Mixer used for ventilation air methane and drawing-out methane and having automatic concentration control function

A mixer and gas technology, applied in the direction of mixers, mixing methods, gas and gas/steam mixing, etc., can solve the problems of not being able to adjust the methane concentration, and the mixer cannot meet the mixing requirements of exhaust gas and exhaust air, etc., to achieve Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in conjunction with accompanying drawing and specific embodiment:

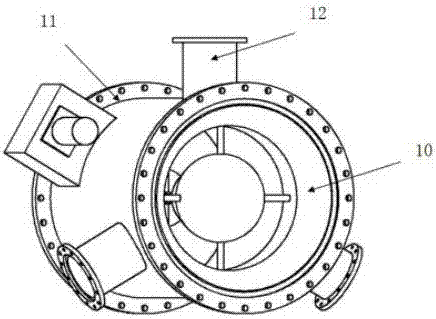

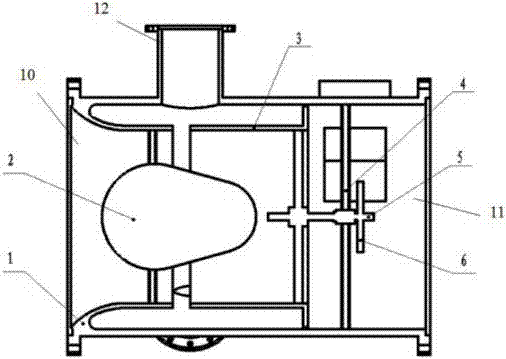

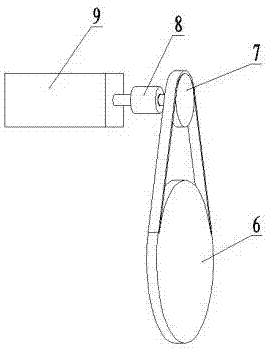

[0018] Such as figure 1 , figure 2 As shown, a kind of exhaust gas and exhaust gas mixer with automatic concentration control function, the mixer has a cylindrical shell 1; the two ends of the shell 1 are exhaust air inlet port 10 and The mixed gas outlet port 11; the exhaust air inlet port 10 and the mixed gas outlet port 11 are provided with flanges to connect with the corresponding pipes; the outer circular surface of the shell 1 has a plurality of exhaust gas outlets uniformly distributed along the circumference Inlet pipe 12; the axis of the exhaust gas inlet pipe 12 is perpendicular to the axis of the housing 1; the number of the exhaust gas inlet pipes is 2-3 to ensure that the exhaust gas can evenly enter the mixer; The exhaust air inlet end 10 of the shell 1 is provided with a transition pipe with a reduced diameter, which is connected with the shell by cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com