Rehabilitating robot and system for ultraviolet curing pipeline

A technology of pipeline repair and ultraviolet light, which is applied in the direction of tube components, special tubes, mechanical equipment, etc., can solve the problems of affecting the curing effect and not being able to adapt to the pipeline, so as to save material costs and time costs, improve curing effects, and consume electricity. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to specific examples and accompanying drawings.

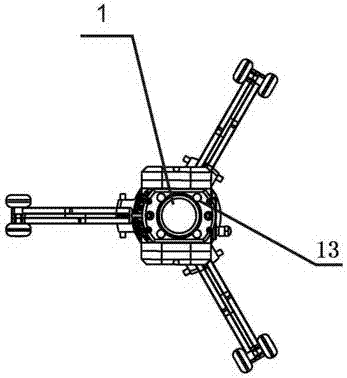

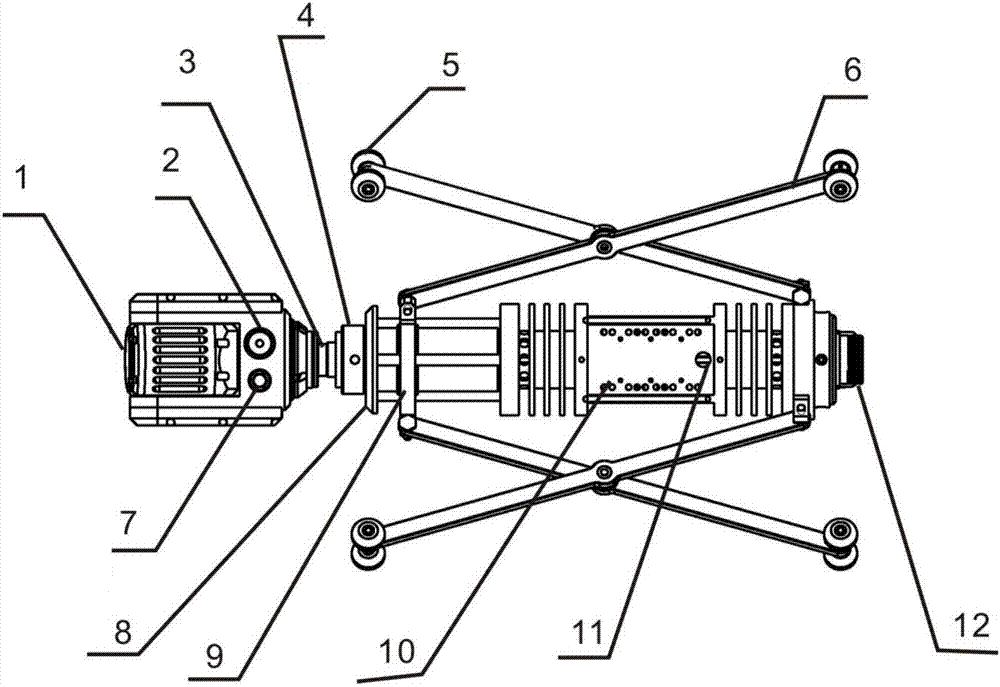

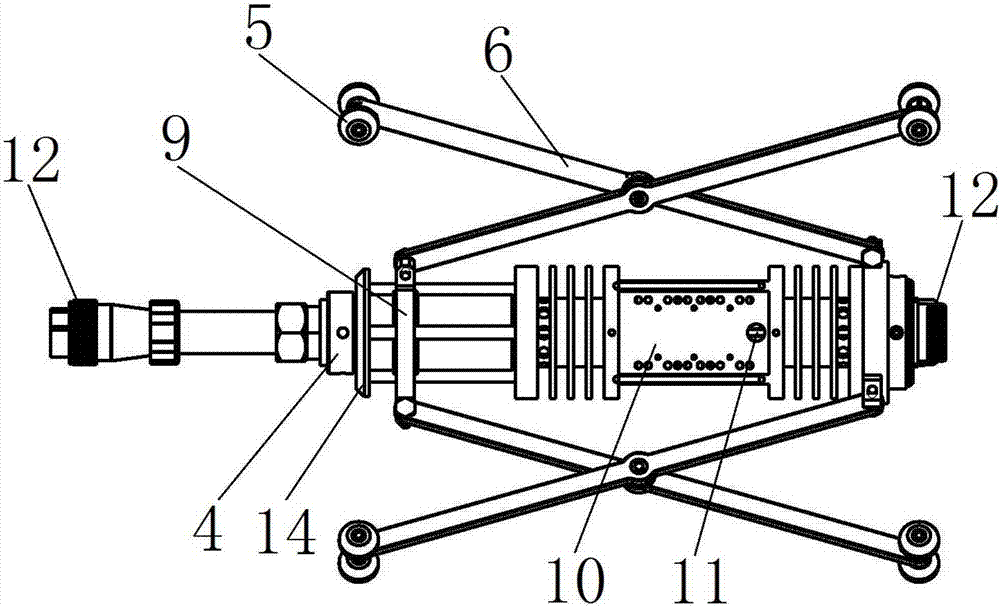

[0027] The invention provides an ultraviolet light curing pipeline repair robot, such as Figure 1 to Figure 6 As shown, the frame body includes a first section frame body 8, a middle section frame body 14 and a tail section frame body 17, wherein the front end of the first section frame body 8 is connected with a front-view camera 1, and an ultraviolet irradiation lamp is fixed on each section frame body. A driving arm 6 is connected to each frame body, and the end of the driving arm 6 is connected with a wheel 5 for rolling on the inner wall of the pipeline. The section frame body 14 and the tail section frame body 17 are connected through the first aviation plug 12, and the end of the tail section frame body 17 is provided with a second aviation plug 15 for connecting the control system through a cable. It includes lamp panels 10 distributed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com