Composite electrolyte of sandwich structure and preparation method thereof

A composite electrolyte and sandwich technology, applied in the direction of electrolytes, solid electrolytes, non-aqueous electrolytes, etc., can solve the problems of low conductivity and poor interface performance of all solid electrolytes, and achieve the effect of simple preparation process, good flexibility and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

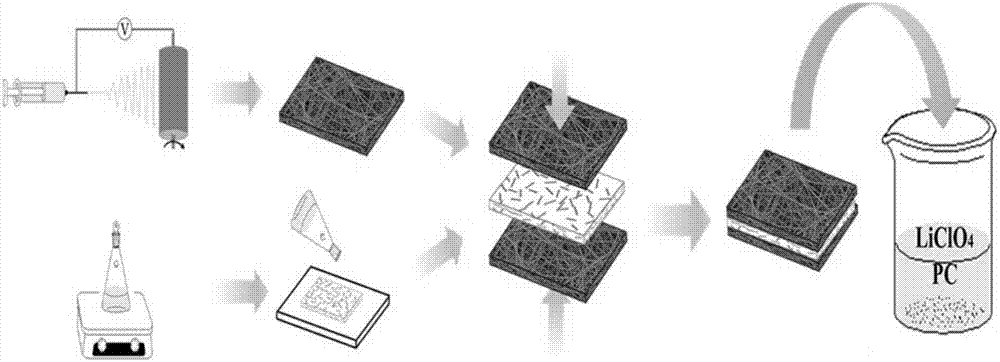

[0024] (1) DMF and DMK are formulated into a mixed solution according to the mass ratio of 1:1 for later use, and an appropriate amount of PVDF powder is added to the above mixed solution to make a solution with a PVDF mass fraction of 17%, and stirred at 60°C for 12 hours to obtain a uniform transparent mixed solution;

[0025] (2) At an injection speed of 1.5ml / h, a spinning voltage of 18kv, electrospinning is carried out under the conditions of using a roller to receive (roller speed 800r / min);

[0026] (3) After spinning, put the electrospun film into an oven, and dry it at 60° C. for 3-48 hours to completely volatilize the solvent. The obtained film is standby;

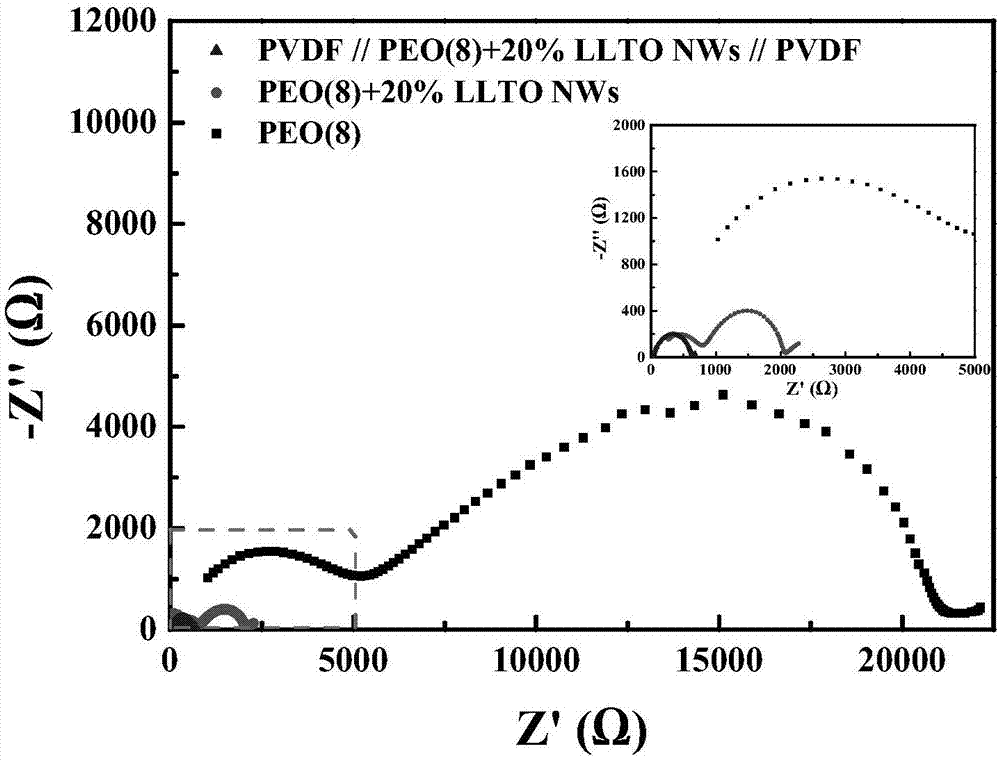

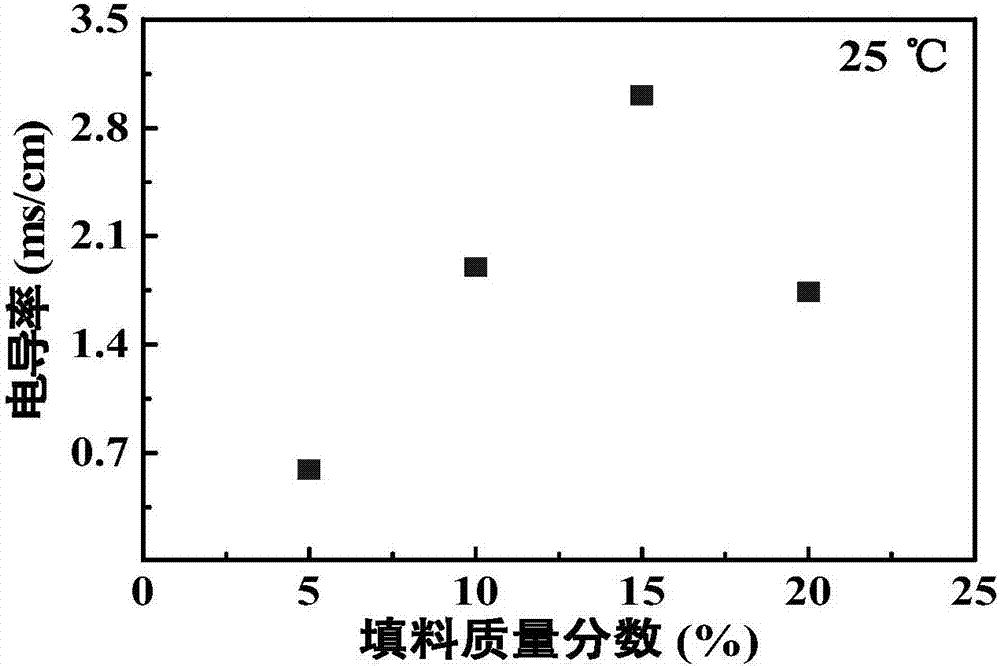

[0027] (4) Take 1g PEO, 0.3g LiClO 4 Put into 10-25ml ACN and stir well to form a homogeneous solution, divide into four parts and add a certain amount of LLTO nanofibers (LLTO NWs) to it to make a mixed solution with a mass fraction of LLTO NWs of 5%, and stir fully at room temperature;

[0028] (5) Put the m...

Embodiment 2

[0032] (1) DMF and DMK are formulated into a mixed solution according to the mass ratio of 1:1 for later use, and an appropriate amount of PVDF powder is added to the above mixed solution to make a solution with a PVDF mass fraction of 17%, and stirred at 60°C for 12 hours to obtain a uniform transparent mixed solution;

[0033] (2) At an injection speed of 1.5ml / h, a spinning voltage of 18kv, electrospinning is carried out under the conditions of using a roller to receive (roller speed 800r / min);

[0034] (3) After spinning, put the electrospun film into an oven, and dry it at 60° C. for 3-48 hours to completely volatilize the solvent. The obtained film is standby;

[0035] (4) Take 1g PEO, 0.3g LiClO 4 Put it into 10-25ml ACN and stir well to form a homogeneous solution, divide it into four parts and add a certain amount of LLTO nanofibers (LLTO NWs) to it to make a mixed solution with a mass fraction of LLTO NWs of 10%, and stir fully at room temperature;

[0036] (5) Pu...

Embodiment 3

[0040] (1) DMF and DMK are formulated into a mixed solution according to the mass ratio of 1:1 for later use, and an appropriate amount of PVDF powder is added to the above mixed solution to make a solution with a PVDF mass fraction of 17%, and stirred at 60°C for 12 hours to obtain a uniform transparent mixed solution;

[0041] (2) At an injection speed of 1.5ml / h, a spinning voltage of 18kv, electrospinning is carried out under the conditions of using a roller to receive (roller speed 800r / min);

[0042] (3) After spinning, put the electrospun film into an oven, and dry it at 60°C for 3-48 hours to completely volatilize the solvent. The obtained film is standby;

[0043] (4) Take 1g PEO, 0.1-0.3g LiClO 4Put into 10-25ml ACN and stir well to form a homogeneous solution, divide into four parts and add a certain amount of LLTO nanofibers (LLTO NWs) to it to make a mixed solution with a mass fraction of LLTO NWs of 15%, and stir fully at room temperature;

[0044] (5) Put the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com