Preparation method of MgAlON ceramic powder based on 3D printing forming

A 3D printing and ceramic powder technology, which is applied in the field of MgAlON ceramic powder preparation based on 3D printing, can solve the problems of macro-preparation of MgAlON ceramic powder and other problems, and achieve the prevention of synthesis reaction, increase the furnace capacity, and facilitate handling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

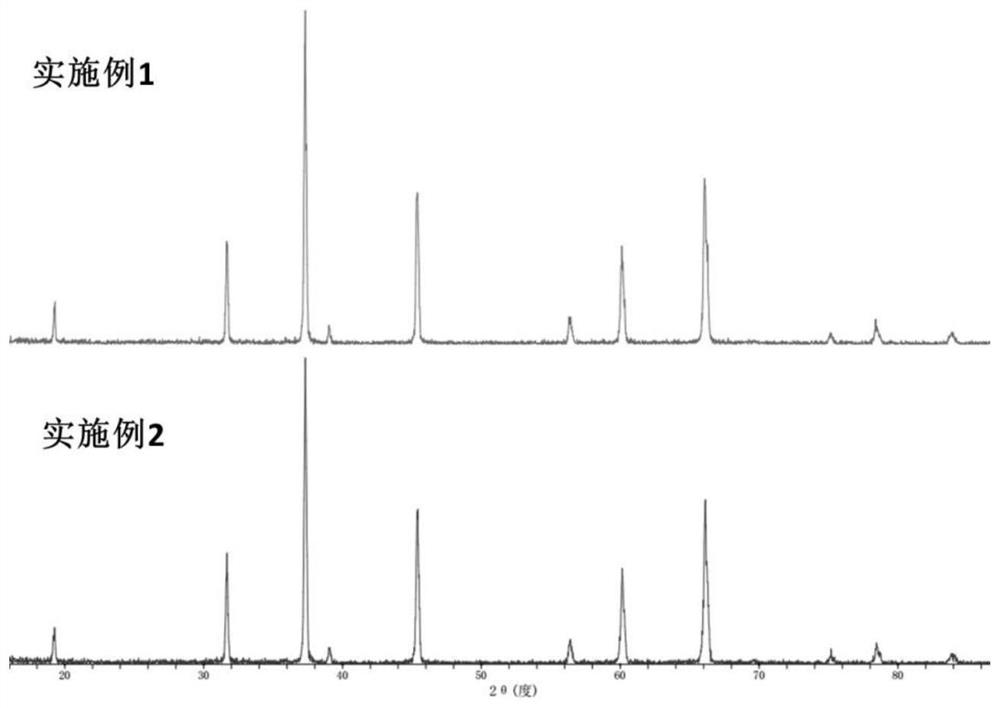

Embodiment 1

[0029] The MgAlON powder is prepared using a ceramic powder preparation method based on 3D printing, which specifically includes the following steps:

[0030] (1) weigh nanoscale γ-A12O3 powder 87.4g, nanoscale MgO powder 8.8g, high-purity carbon black powder 3.8g, polyethylene glycol 5g, urea 0.5g, ammoniacal liquor 0.5g, composite solvent 125g (by water, A mixed liquid composed of tert-butanol (75%, 25% by weight) and alumina balls was put into a polyurethane ball mill jar, and ball milled on a homogenizer at a speed of 2000r / min for 2min to obtain a solid phase content of about 44% raw ink;

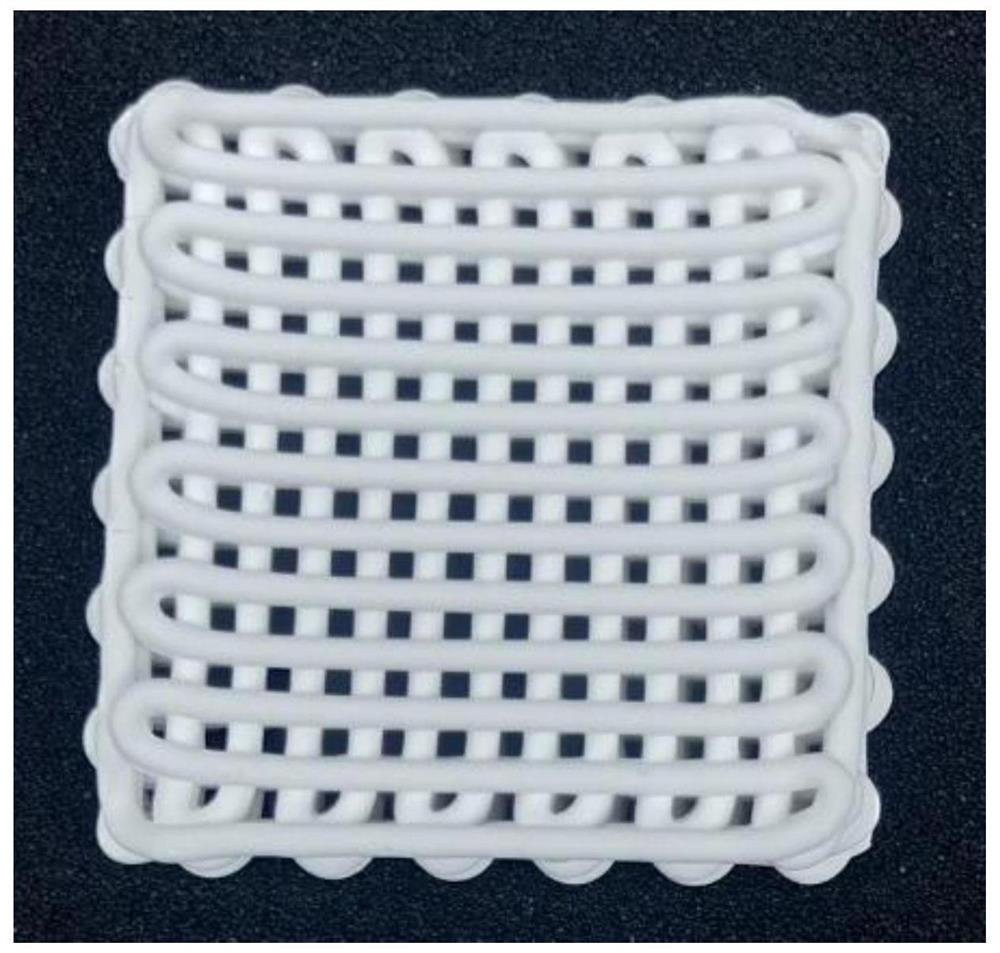

[0031] (2) Inject the above raw material ink into the barrel of the 3D printer for printing and molding. The diameter of the printing nozzle is 2mm, the printing pressure is 180kPa, and the printing speed is 15mm / s. After printing, put the raw material body into a drum with a temperature of 100°C Dried for 12 hours in an air oven to obtain a raw material body with an internal regular ...

Embodiment 2

[0035] The MgAlON powder is prepared using a ceramic powder preparation method based on 3D printing, which specifically includes the following steps:

[0036] (1) Weigh 87.5g of nanoscale α-A12O3 powder, 8.5g of nanoscale MgO powder, 4.0g of high-purity carbon black powder, 4g of polyvinyl alcohol, 0.4g of tetramethylammonium hydroxide, 0.4g of ammonia water, and 112g of composite solvent (the mixed liquid that is made up of water, tert-butanol, proportion by weight is 80%, 20% respectively) and aluminum oxide grinding ball, put into the plastic container and stir, fully grind on the three-roller mill then, obtain solid phase content approx. 47% raw ink;

[0037] (2) Inject the above raw material ink into the barrel of the 3D printer for printing and molding. The diameter of the printing nozzle is 3mm, the printing pressure is 120kPa, and the printing speed is 15mm / s. Dry in a freeze dryer for 24 hours to obtain a raw material body with an internal regular three-dimensional t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com