Porous MoS2 hydrogel as well as preparation method and application thereof

A hydrogel and moisture technology, applied in gel preparation, water/sewage treatment, general water supply conservation, etc., can solve the problem of not being able to achieve high steam evaporation rate and anti-salt performance at the same time, the material is not friendly to the environment, and the material has poor mechanical properties and other problems, to achieve excellent anti-salt performance, high-efficiency desalination yield, mild effect on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

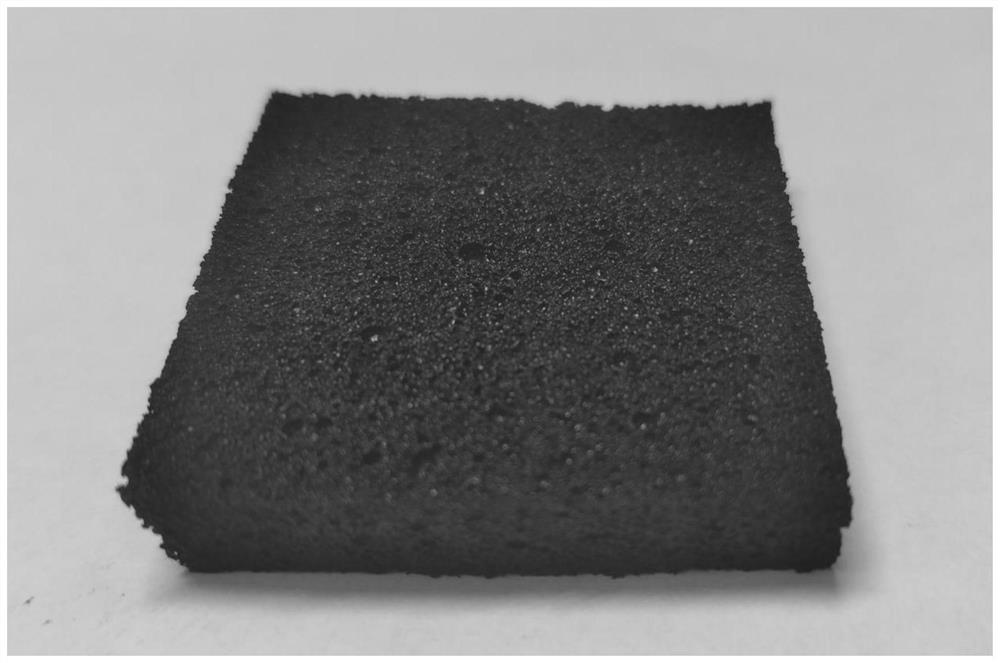

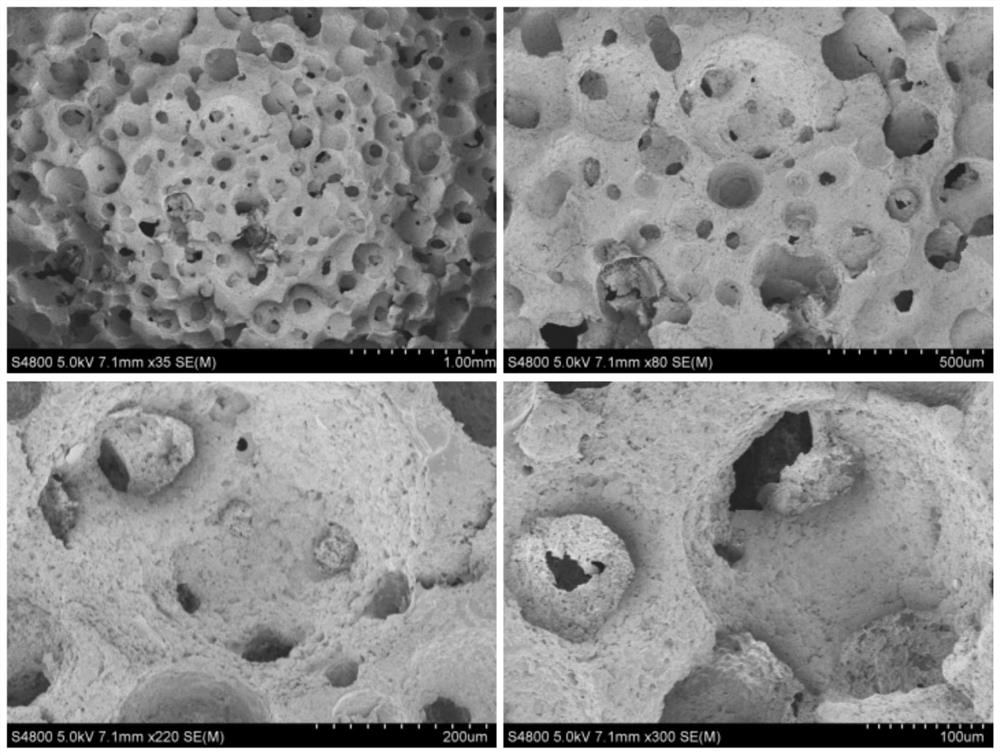

[0028] A kind of porous MoS provided by the embodiment of the present invention 2 The preparation method of hydrogel comprises the following steps:

[0029] S1, MoS 2 Preparation of molybdate, thiourea and water in a reactor to react to obtain a black substance, then wash and dry the black substance to obtain MoS 2 nanomaterials. Preferably, the reactor is a reactor with a polytetrafluoroethylene liner. Petal-shaped MoS can be prepared by reacting molybdate, thiourea and water in a reactor 2 nanomaterials. MoS 2 Nanomaterials have a wide light absorption range and high solar energy absorption rate, so they can be used as light-to-heat conversion materials.

[0030] Further, in a preferred embodiment of the present invention, the molybdate includes ammonium molybdate tetrahydrate or sodium molybdate dihydrate, and the mass ratio of the molybdate, the thiourea and the water is 2- 3: 4-5: 60-80.

[0031] Further, in a preferred embodiment of the present invention, the rea...

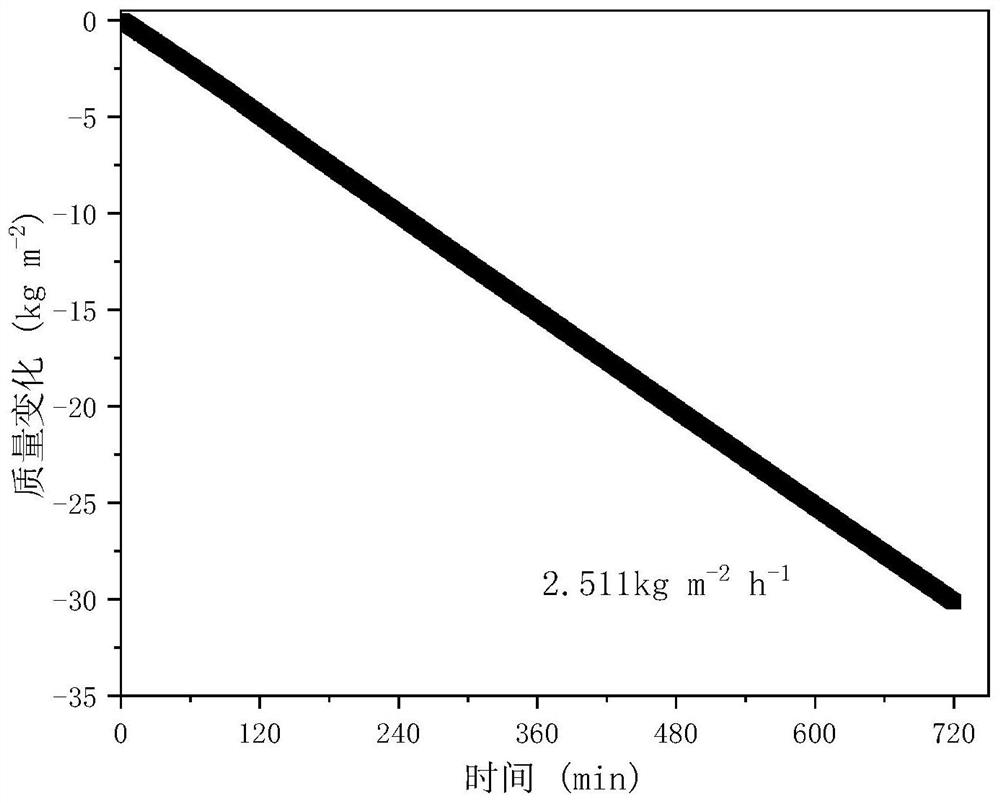

Embodiment 1

[0047] A kind of porous MoS provided by this embodiment 2 Hydrogel, which is prepared according to the following steps:

[0048] (1)MoS 2 Preparation: Put ammonium molybdate tetrahydrate, thiourea, and water into a reaction kettle with a polytetrafluoroethylene lining at a mass ratio of 2:4:60, react at 210°C for 8 hours, and then take it out to obtain a black substance. The above-mentioned black substance was washed alternately with ultrapure water and absolute ethanol for 5 times, and then dried in an oven at 100 °C until the water was completely removed, and the petal-shaped MoS was obtained. 2 nanomaterials.

[0049] (2) Slurry preparation: MoS 2 , acrylamide, N, N'-methylenebisacrylamide and water are put into a ball mill tank at a mass ratio of 5:3:0.2:20, and the ball mill is used to grind and make pulp for 2 hours.

[0050] (3) Stirring and foaming of the slurry by mechanical stirring: Take out 20 mL of the slurry prepared in step (2), add 0.02 g of a surfactant, a...

Embodiment 2

[0054] A kind of porous MoS provided by this embodiment 2 Hydrogel, which is prepared according to the following steps:

[0055] (1)MoS 2 Preparation: Put ammonium molybdate tetrahydrate, thiourea, and water into a reaction kettle with a polytetrafluoroethylene lining at a mass ratio of 3:5:80, react at 210°C for 8 hours, and then take it out to obtain a black substance. The above-mentioned black substance was washed alternately with ultrapure water and absolute ethanol for 5 times, and then dried in an oven at 100 °C until the water was completely removed, and the petal-shaped MoS was obtained. 2 nanomaterials.

[0056] (2) Slurry preparation: MoS 2 , acrylamide, N, N'-methylenebisacrylamide and water are put into a ball mill tank at a mass ratio of 5:3:0.2:20, and the ball mill is used to grind and make pulp for 2 hours.

[0057] (3) Stirring and foaming of the slurry by mechanical stirring: Take out 20 mL of the slurry prepared in step (2), add 0.02 g of a surfactant, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com