Saw chain for felling saw

A technology for logging saws and saw chains, applied in the field of electric logging saws, which can solve the problems of prone to strain, decreased shear resistance of rivets, and potential safety hazards, and achieve improved stability, excellent shear resistance, and guaranteed firmness and The effect of safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

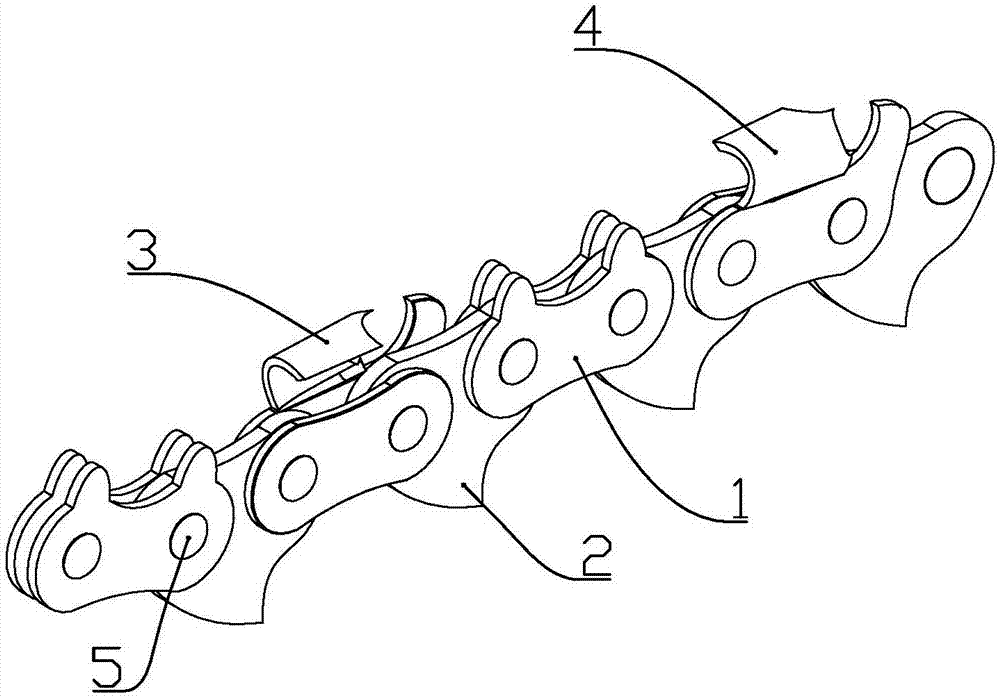

[0041] according to Figure 1 to Figure 12 As shown, this embodiment is a saw chain of a logging saw, including a connecting link 1 and a cutting link connected by a driving piece 2, and the driving piece is connected to the connecting link and the cutting link through rivets respectively. Rotationally connected, the cutting chain link includes a left cutting chain link 3 and a right cutting chain link 4 arranged in turn.

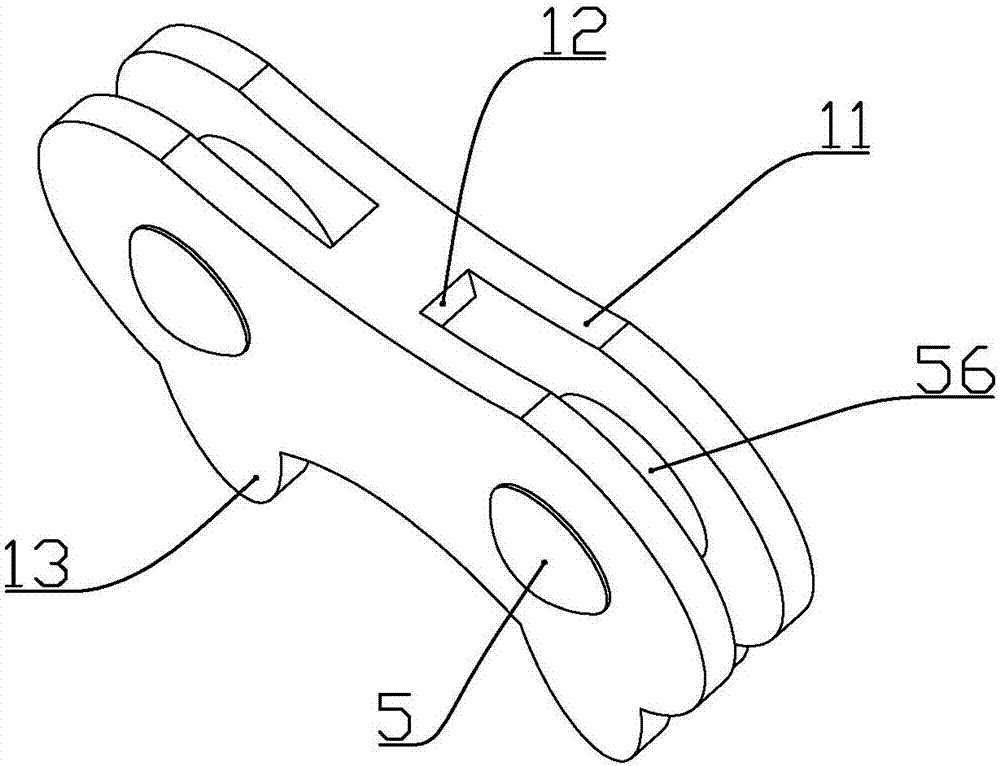

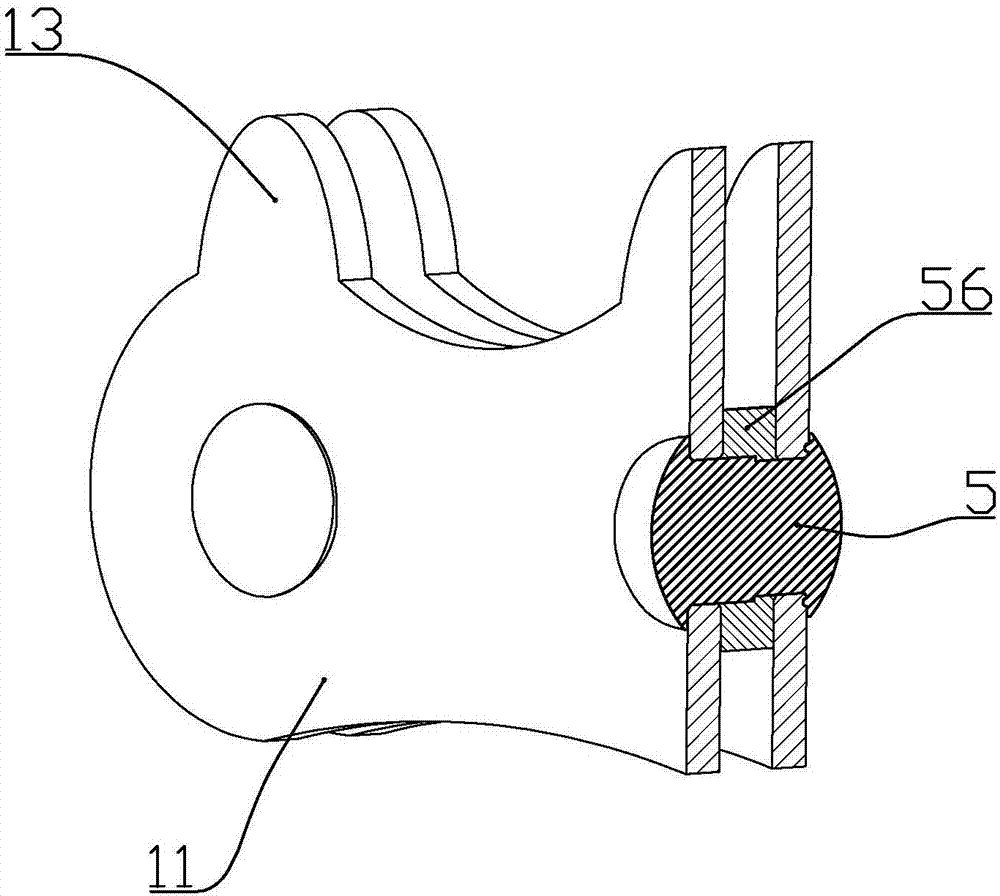

[0042] The connecting link is composed of two connecting pieces 11 and a connecting part 12 integrally connected between the two connecting pieces and located in the middle of the length direction. The connecting link is stamped and formed by a complete metal sheet; Two large connection holes 62 are provided on the sheet, and two small connection holes 61 are provided at the position corresponding to the two large connection holes on the other said connection sheet, and the aperture of the small connection hole is smaller than the aperture of the large conn...

Embodiment 2

[0056] combine Figure 5 to Figure 15 As shown, this embodiment is a saw chain of a logging saw, including a connecting link 1 and a cutting link connected by a driving piece 2, and the driving piece is connected to the connecting link and the cutting link through rivets respectively. Rotationally connected, the cutting chain link includes a left cutting chain link 3 and a right cutting chain link 4 arranged in turn.

[0057]The connecting link is composed of two connecting pieces 11 and a connecting part 12 integrally connected between the two connecting pieces and located in the middle of the length direction. The connecting link is stamped and formed by a complete metal sheet; Two large connection holes 62 are provided on the sheet, and two small connection holes 61 are provided at the position corresponding to the two large connection holes on the other said connection sheet, and the aperture of the small connection hole is smaller than the aperture of the large connection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com