Method for one-step hydrothermal synthesis of different-morphology bismuth tungstate two-dimensional photocatalytic materials

A photocatalytic material, bismuth tungstate technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of long time, high reaction temperature, nanosheets Thickness and other problems, to achieve the effect of short preparation cycle, simple operation, green raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

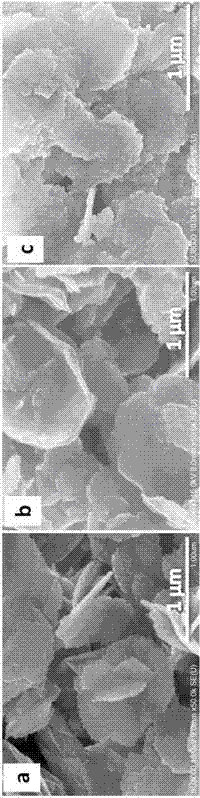

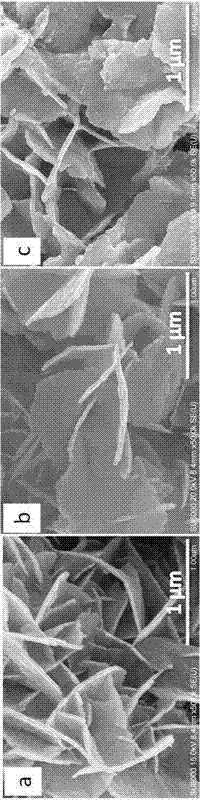

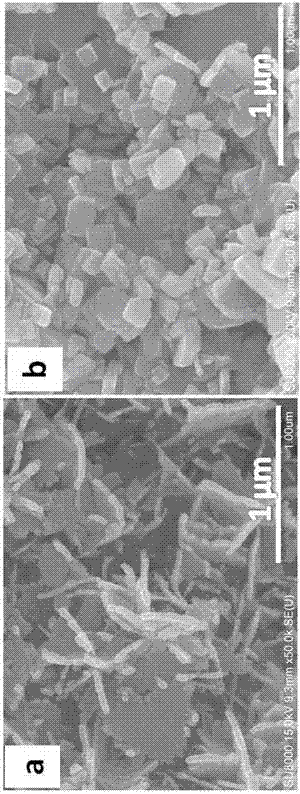

Embodiment 1

[0035] Weigh 165mg of sodium tungstate and 25mg of cetyltrimethylamine bromide into 40mL of deionized water, stir to dissolve completely, then add 361mg of bismuth nitrate pentahydrate to the above clear solution, continue to stir for 40min, and add the obtained solution to Put the autoclave into a high-pressure reactor, seal the autoclave and put it in a drying oven at a constant temperature of 120°C for 24 hours. After the reaction, cool it down to room temperature naturally. After the product is taken out, it is centrifuged and dried to obtain two-dimensional bismuth tungstate nanosheets.

Embodiment 2

[0037]Weigh 33mg of sodium tungstate and 5mg of cetyltrimethylamine bromide into 40mL of deionized water, stir to dissolve completely, then add 72.2mg of bismuth nitrate pentahydrate to the above clear solution, and continue stirring for 40min to obtain a solution Put it into a high-pressure reactor, seal the high-pressure reactor and put it in a drying oven to react at a constant temperature of 120°C for 24 hours. After the reaction, naturally cool to room temperature, take out the product, centrifuge and dry to obtain two-dimensional bismuth tungstate nanosheets .

Embodiment 3

[0039] Weigh 16.5 mg of sodium tungstate and 2.5 mg of cetyltrimethylamine bromide into 40 mL of deionized water, stir to dissolve them completely, then add 36.1 mg of bismuth nitrate pentahydrate to the above clear solution, and continue stirring for 40 min to obtain Add the solution into the autoclave, seal the autoclave and put it in a drying oven at 120°C for 24 hours of constant temperature reaction. After the reaction, cool it down to room temperature naturally, take out the product, centrifuge and dry to obtain two-dimensional bismuth tungstate Nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com