Laser welding machine

A laser welding machine and laser emission technology, applied in laser welding equipment, welding equipment, welding equipment, etc., can solve the problems of low welding yield, high production cost, and affecting the quality of cladding welding and sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

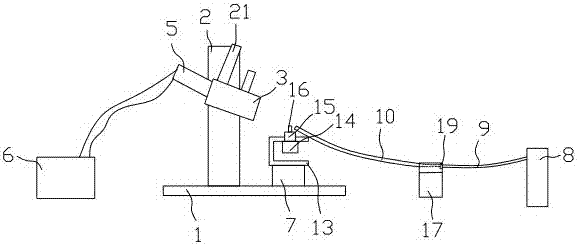

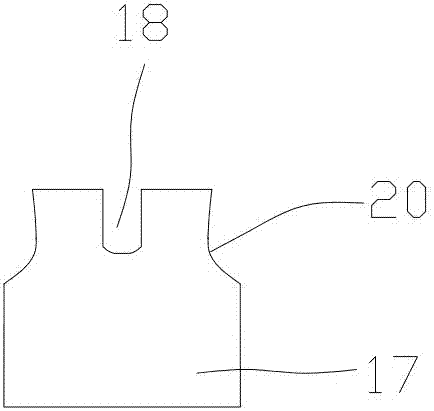

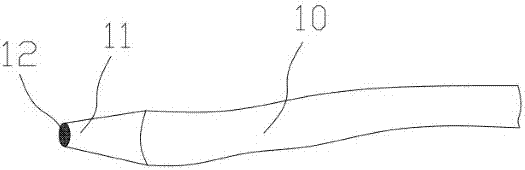

[0011] A laser welding machine such as Figure 1 to Figure 5 As shown, including a base 1, a mounting bracket 2 is provided on the base 1, a laser emitting head 3 is installed on the mounting bracket 2, and a monitor 5 for monitoring the welding process of the cladding 4 is connected to the laser emitting head 3. The monitor 5 is connected to the display 6 circuit, and the side of the laser emitting head 3 is provided with a cladding fixture that drives the cladding 4 to rotate relative to the laser emitting head 3, and the bottom of the cladding fixture is provided with a drive cladding fixture to lift and translate The mobile module 7, the mobile module 7 is installed on the base 1, and the base 1 is also provided with an argon gas bottle 8, the argon gas bottle 8 is connected with the argon gas outlet pipe 9, and the argon gas outlet pipe 9 is connected with the bamboo tube 10 connection, the free end of the bamboo tube 10 is provided with a nozzle 11, and the nozzle 11 of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com