Method for preparing ordered mesoporous carbon microspheres

A mesoporous carbon and microsphere technology, which is applied in the preparation/purification of carbon, etc., can solve the problems of increased reaction cost, influence of ordered pore structure of products, and difficult control of reaction conditions, and achieves mild reaction conditions, abundant raw materials, shortened The effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Using straw as raw material and surfactant sodium dodecylsulfonate as soft template, weigh 1g of template agent and dissolve it in 30ml of water, stir continuously in a water bath at 60°C until it is completely dissolved, and weigh 10g of ground straw powder and mix it with After mixing, transfer it to a polytetrafluoroethylene-lined reactor with a volume of 100ml, ensure that the volume of the solution and the volume of the kettle are 13:20, raise the temperature to the target temperature of 260°C at a heating rate of 5°C / min, keep the temperature for 16 hours, and cool down to room temperature The dark brown solid was collected by filtration, washed until the filtrate was colorless, and then ground. The obtained powder was placed in a tubular calciner, and carbonized at 800°C for 1 hour under the protection of nitrogen atmosphere to remove the template agent, and carbon microspheres with ordered mesoporous structure were obtained. .

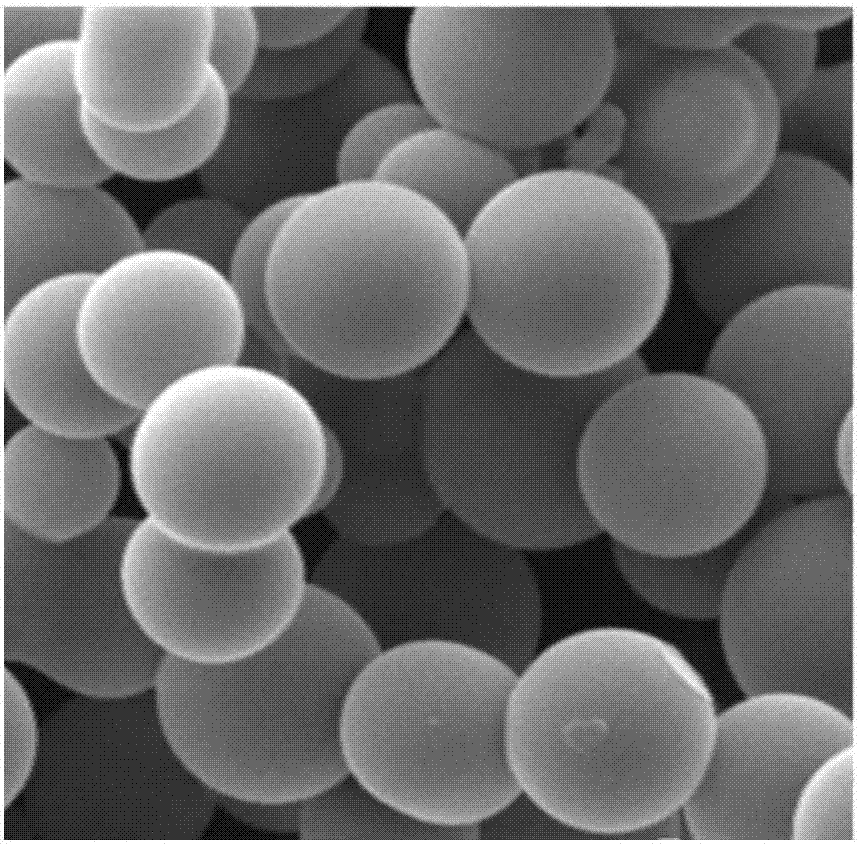

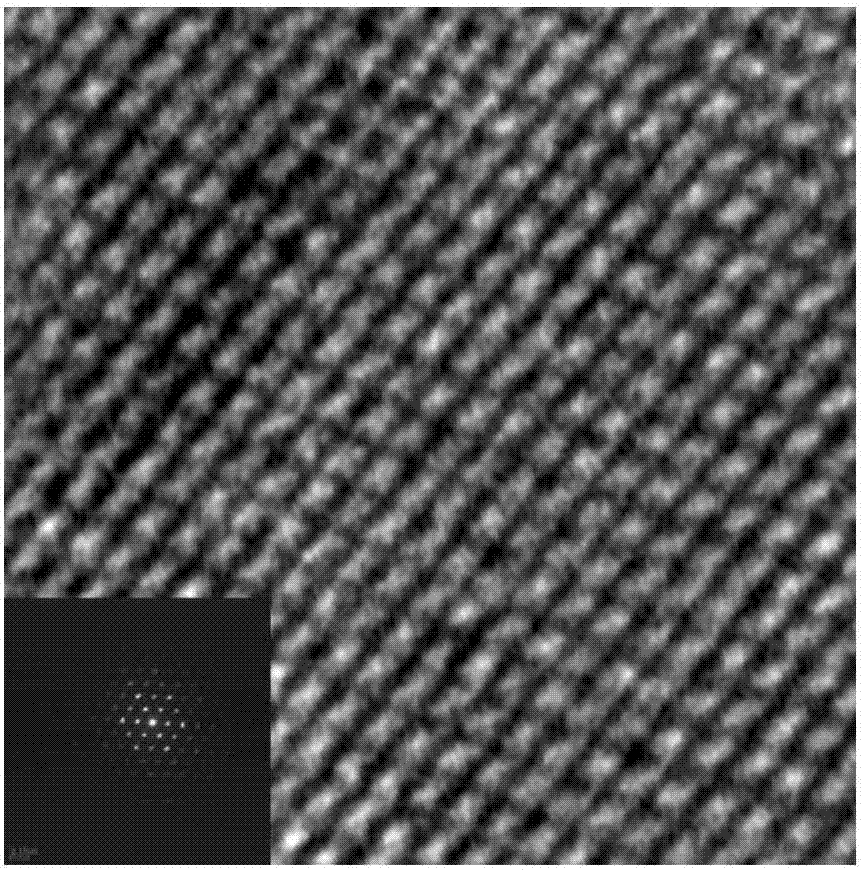

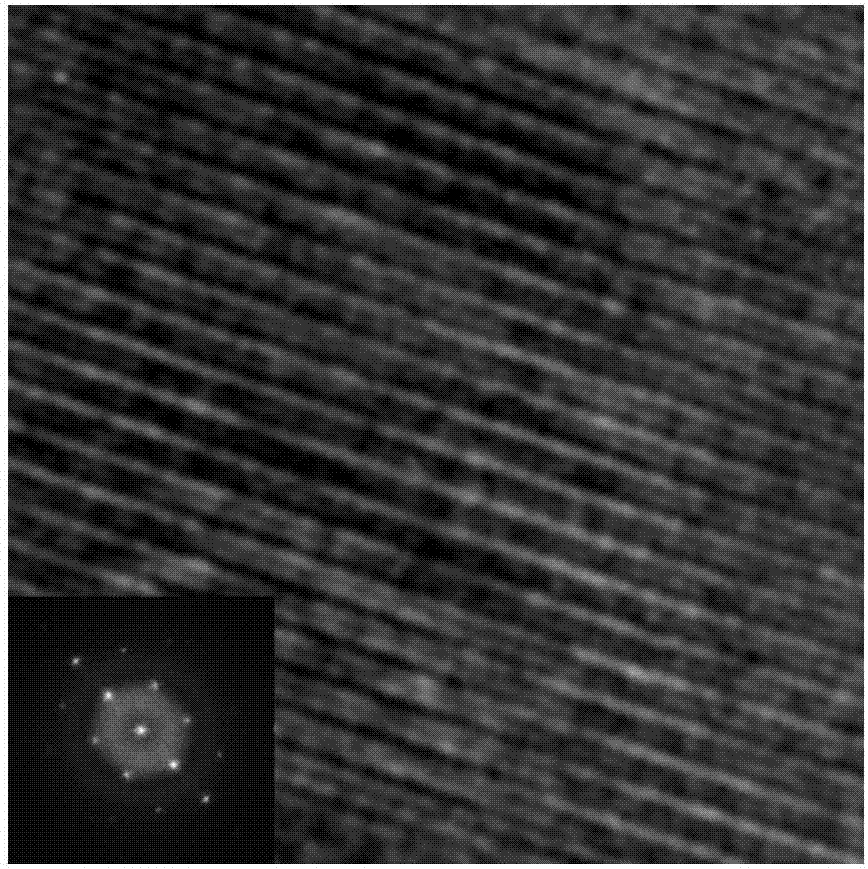

[0024] The material prepared by t...

Embodiment 2

[0026] Using rice straw as raw material and surfactant P123 as soft template, weigh 0.5g of template agent and dissolve it in 30ml of water, stir continuously in a 60°C water bath until it is completely dissolved, then weigh 4g of rice straw powder and mix it with it, then transfer it to a 100ml In a polytetrafluoroethylene-lined reactor, ensure that the volume of the solution and the volume of the kettle are 13:20, the temperature is raised to the target temperature of 220°C at a heating rate of 5°C / min, and the temperature is kept at a constant temperature for 14 hours. After cooling down to room temperature, the dark brown solid is collected by filtration and washed until The filtrate was colorless and ground, and the obtained powder was put into a tubular calciner, and carbonized at 900°C for 2 hours under the protection of nitrogen atmosphere to remove the template agent, and carbon microspheres with ordered mesoporous structure were obtained.

[0027] The material prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com