All-solid waste filling material for stabilizing dioxin-containing incineration fly ash and preparation method thereof

A technology for incinerating fly ash and filling material, applied in the field of all-solid waste filling material and preparation, can solve the problems of pollution cost, low early strength, high cost of cement filling and mining, and achieve the effect of saving land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

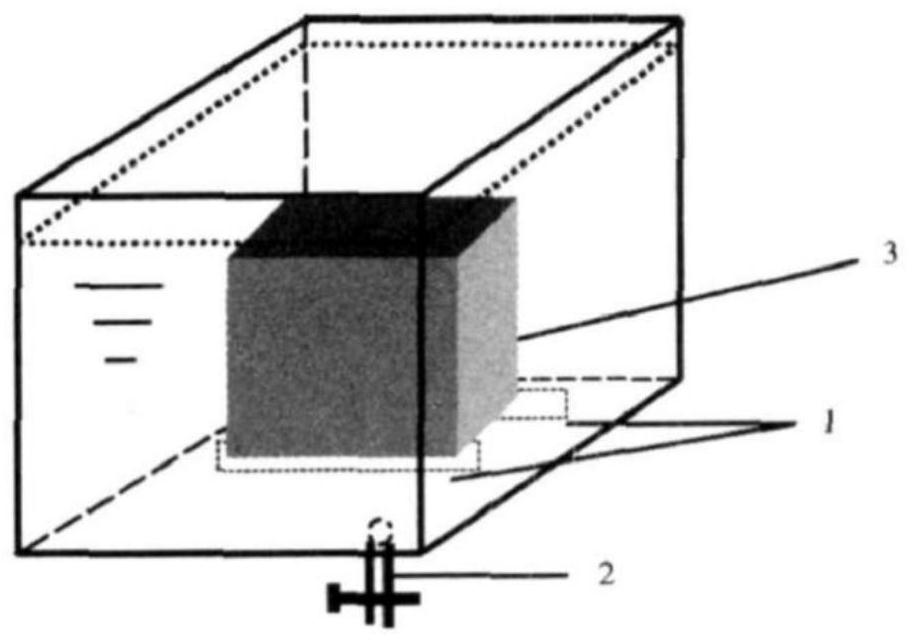

Image

Examples

Embodiment 1

[0040] An all-solid waste filling material is prepared from the following raw materials in weight percentage:

[0041] Slag 70%

[0042] Desulfurized gypsum 15%

[0043] Waste incineration fly ash 15%

[0044] A preparation method for all-solid waste filling materials used for stabilizing dioxin-containing waste incineration fly ash, specifically: adding water and mixing the activated cement, aggregate and water reducing agent evenly, the specific steps are as follows:

[0045] (1) Dry the required raw material slag, steel slag, industrial by-product gypsum, and waste incineration fly ash to a moisture content of 0.01% to 0.1%, and then dry the slag, desulfurized gypsum, and waste incineration fly ash by weight percentage on a dry basis. 70%, 15%, and 15% are individually ground to a specific surface area of 380, 315, and 120m 2 / Kg mixes in the blender and makes cementing agent;

[0046] (2) The weight ratio of cement / aggregate is 1 / 4, the mass fraction of slurry is 80%...

Embodiment 2

[0060] An all-solid waste filling material is prepared from the following raw materials in weight percentage:

[0061] Slag 20%

[0062] Steel slag 5%

[0063] Phosphogypsum 5%

[0064] Granulated ferrochrome slag 15%

[0065] Waste incineration fly ash 55%

[0066] A preparation method for stabilizing all-solid waste filling materials containing dioxin-containing waste incineration fly ash, the details are as follows: the activated cement, aggregate and water reducing agent are mixed evenly with water, and the specific steps are as follows:

[0067] (1) Dry the required raw materials slag, steel slag, phosphogypsum, granulated ferrochrome slag, and waste incineration fly ash to a moisture content of 0.01% to 0.1%, and then dry the slag, steel slag, phosphogypsum, and granulated ferrochrome slag , Garbage incineration fly ash is separately ground to a specific surface area of 380, 350, 325, 405, 150m3 at 20%, 5%, 5%, 15%, 55% by weight percentage on a dry basis 2 / Kg mi...

Embodiment 3

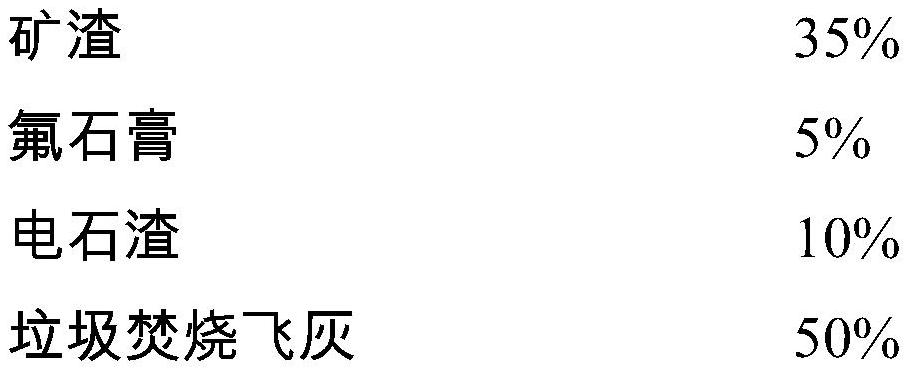

[0082] A filling material for mines, prepared from the following raw materials in weight percent:

[0083]

[0084] A preparation method for stabilizing all-solid waste filling materials containing dioxin-containing waste incineration fly ash, the details are as follows: the activated cement, aggregate and water reducing agent are mixed evenly with water, and the specific steps are as follows:

[0085] (1) Dry the required raw materials slag, fluorine gypsum, carbide slag, and waste incineration fly ash to a moisture content of 0.01% to 0.1%, and then dry the slag, fluorine gypsum, calcium carbide slag, and waste incineration fly ash by weight percentage on a dry basis Separately grind at 35%, 5%, 10%, and 50% to specific surface areas of 400, 280, 320, and 100m 2 / Kg and mixed in a blender to prepare the cement;

[0086] (2) The weight ratio of cement / aggregate is 1 / 3, the mass fraction of slurry is 76%, and the qualified cemented filling material for mine can be obtained b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com