Purification method and device dioxins in solid waste incineration fume

A technology for incinerating flue gas and solid waste, applied in chemical instruments and methods, separation methods, combined devices, etc., can solve problems such as unsatisfactory effects, and achieve the effects of reduced fly ash, low consumption, and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

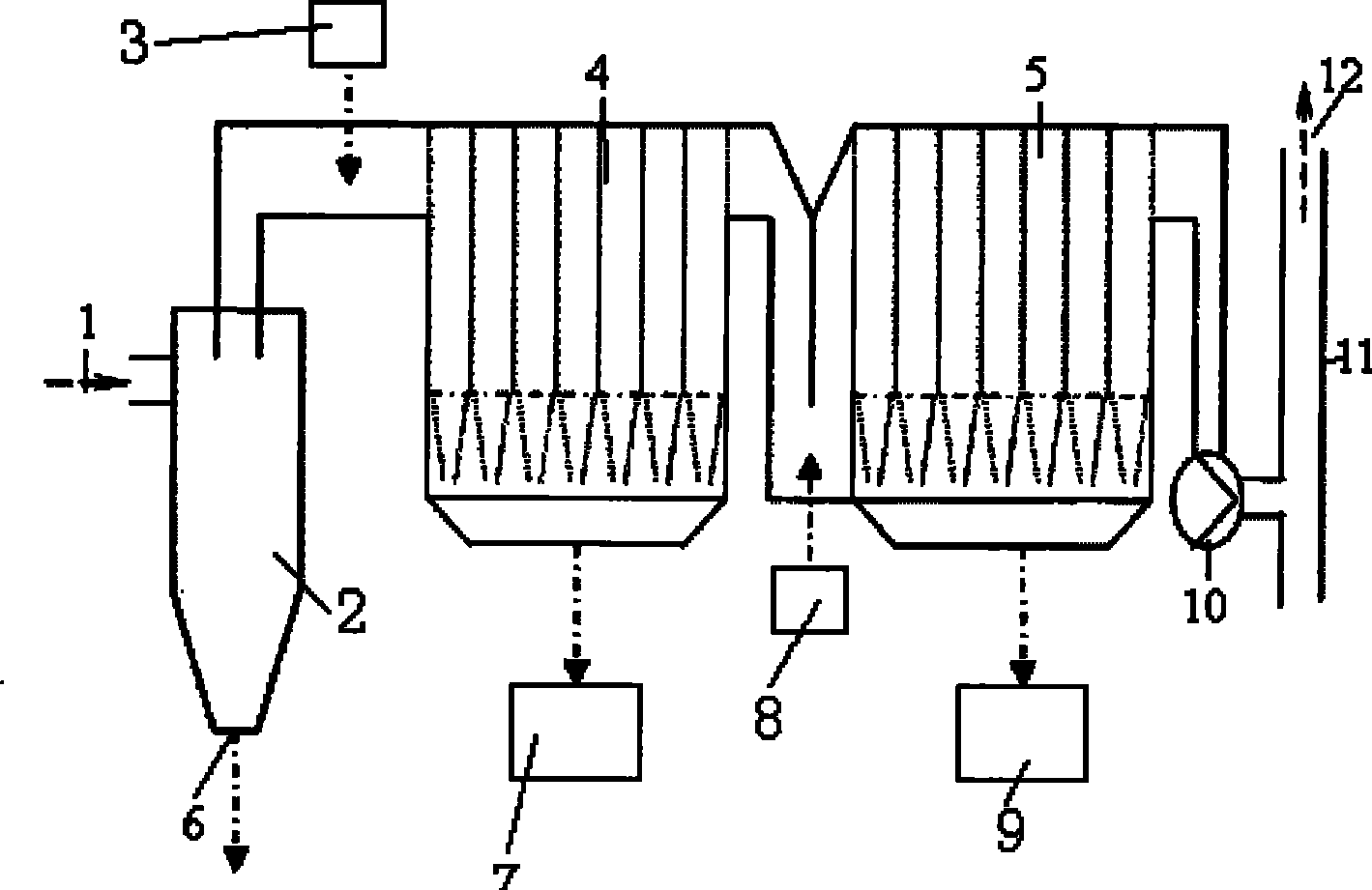

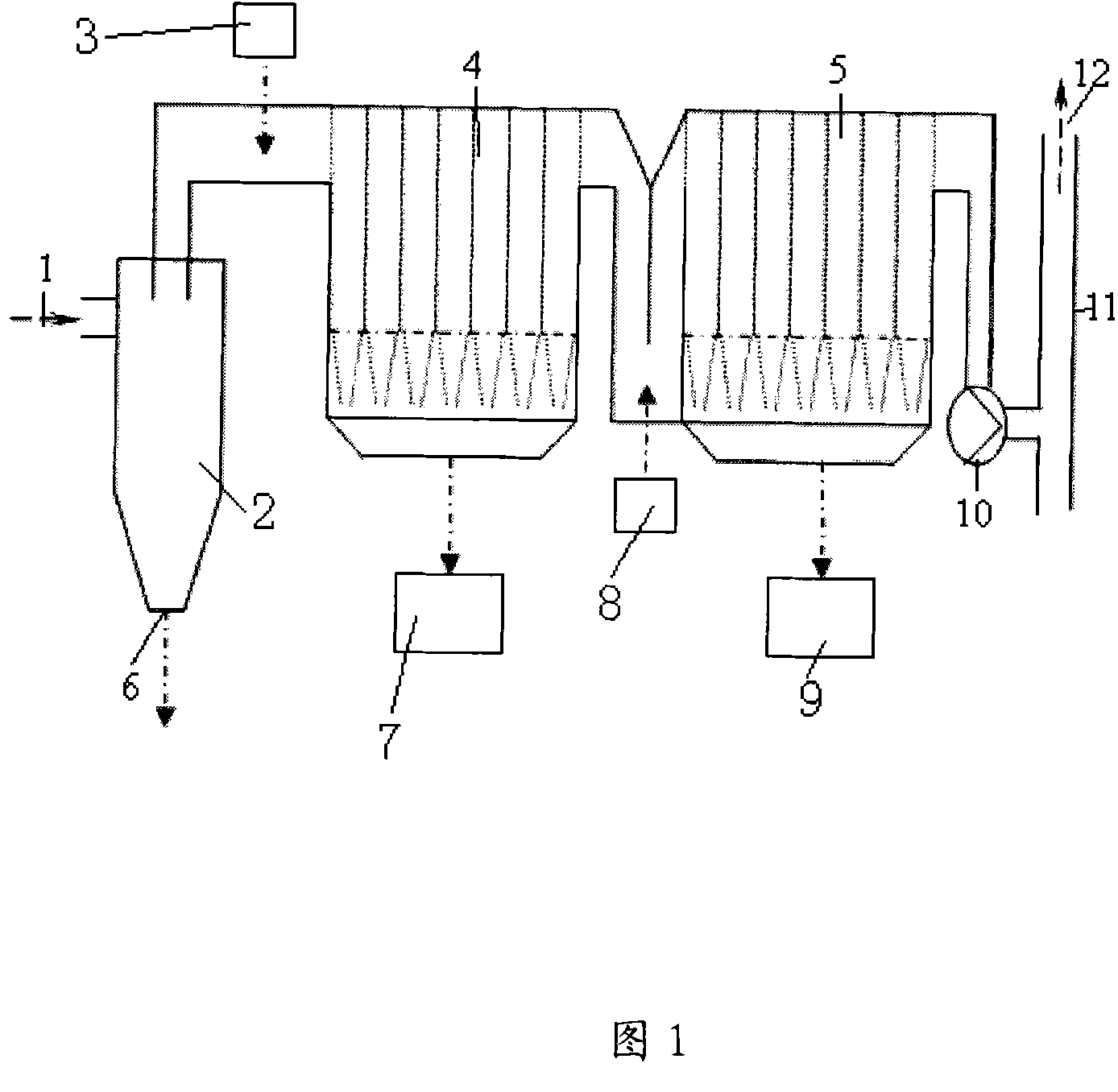

[0029] Example 1 Purification equipment for dioxin in solid waste incineration flue gas

[0030] As shown in Figure 1, the equipment used in the purification method of dioxin in the solid waste incineration flue gas comprises a cyclone dust collector 2, and the downstream of the cyclone dust collector 2 is connected with a first-stage bag filter 4, and the cyclone dust collector 2 and the first A modified activated carbon injection device 3 is arranged between the first-stage bag filter 4; A fresh activated carbon injection device 8 is provided, and the downstream of the second-stage bag filter 5 is connected to a chimney 11 through an induced draft fan 10 .

[0031] The cyclone dust collector is provided with an ash outlet 6 of the cyclone dust collector.

[0032] The first-stage bag filter is provided with a first-stage bag filter fly ash collection bin 7 .

[0033] The second-stage bag filter is provided with a waste activated carbon collection bin 9 for the second-stage ...

Embodiment 2

[0034] Example 2 Purification method of dioxin in solid waste incineration flue gas

[0035] Below in conjunction with accompanying drawing 1, the method for purifying dioxins in the solid waste incineration flue gas of the present invention will be further described.

[0036] As shown in Figure 1, the temperature is 150-200°C, and the solid waste incineration flue gas 1 after dry or semi-dry removal of acid gas has an original particle content of 1.5-6g / Nm 3 , into the cyclone dust collector 2, the flue gas velocity is 8 ~ 10m / s. More than 90% of the particles with a diameter of more than 10 μm are removed in the cyclone dust collector 2 .

[0037] The modified activated carbon is injected into the cyclone dust collector and the first-stage bag filter through the modified activated carbon injection device 3, and the air or steam delivery medium is sprayed countercurrently into the connecting pipe of the first-stage bag filter to mix with the flue gas. The modified activated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com