All solid waste filling material for stabilizing dioxin incineration fly ash and preparation method thereof

A technology for incinerating fly ash and filling material, which is applied in the field of solid waste filling material and preparation, can solve the problems of waste of resources, environmental pollution, low early strength, etc., and achieves simple and easy operation of the preparation method, saving a large area of land, and environmental pollution. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

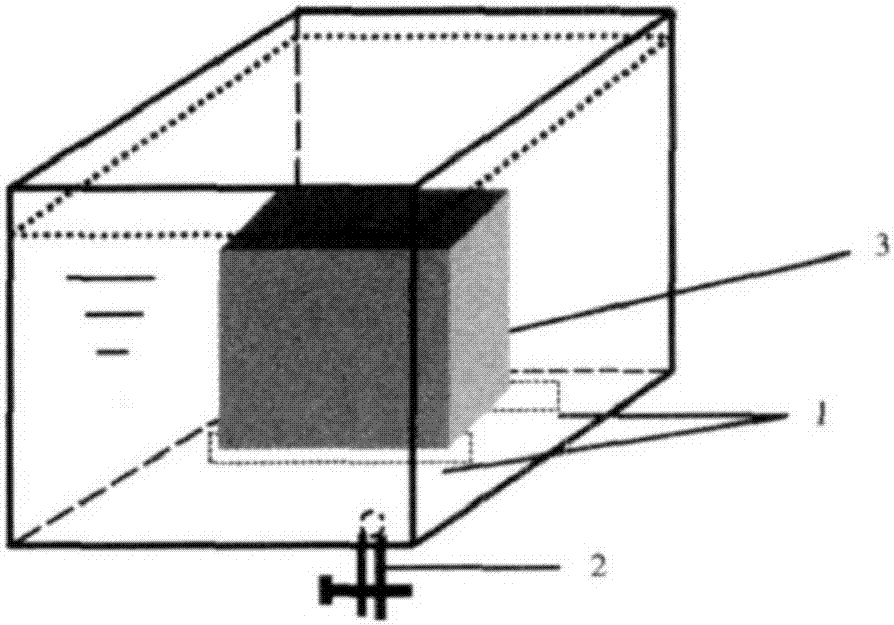

Image

Examples

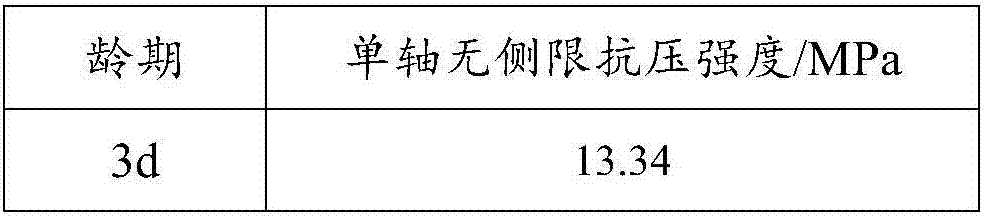

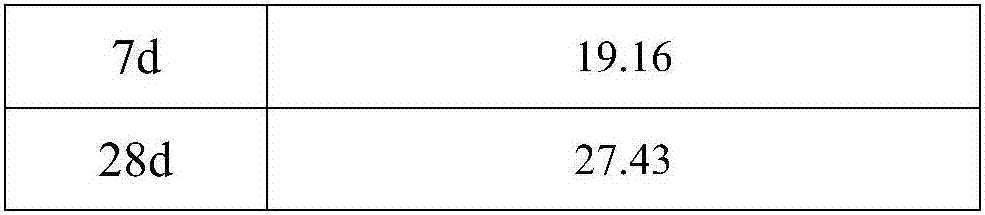

Embodiment 1

[0040] An all-solid waste filling material is prepared from the following raw materials in weight percentage:

[0041] Slag 70%

[0042] Desulfurized gypsum 15%

[0043] Waste incineration fly ash 15%

[0044] A preparation method for all-solid waste filling materials used for stabilizing dioxin-containing waste incineration fly ash, specifically: adding water and mixing the activated cement, aggregate and water reducing agent evenly, the specific steps are as follows:

[0045] (1) Dry the required raw material slag, steel slag, industrial by-product gypsum, and waste incineration fly ash to a moisture content of 0.01% to 0.1%, and then dry the slag, desulfurized gypsum, and waste incineration fly ash by weight percentage on a dry basis. 70%, 15%, and 15% are individually ground to a specific surface area of 380, 315, and 120m 2 / Kg mixes in the blender and makes cementing agent;

[0046] (2) The weight ratio of cement / aggregate is 1 / 4, the mass fraction of slurry is 80%...

Embodiment 2

[0061] An all-solid waste filling material is prepared from the following raw materials in weight percentage:

[0062]

[0063] A preparation method for stabilizing all-solid waste filling materials containing dioxin-containing waste incineration fly ash, the details are as follows: the activated cement, aggregate and water reducing agent are mixed evenly with water, and the specific steps are as follows:

[0064] (1) Dry the required raw materials slag, steel slag, phosphogypsum, granulated ferrochrome slag, and waste incineration fly ash to a moisture content of 0.01% to 0.1%, and then dry the slag, steel slag, phosphogypsum, and granulated ferrochrome slag , Garbage incineration fly ash is separately ground to a specific surface area of 380, 350, 325, 405, 150m3 at 20%, 5%, 5%, 15%, 55% by weight percentage on a dry basis 2 / Kg mixes in the blender and makes cementing agent;

[0065] (2) The cementing agent / aggregate weight ratio is 1 / 1, the mass fraction of the slurr...

Embodiment 3

[0079] A filling material for mines, prepared from the following raw materials in weight percent:

[0080]

[0081] A preparation method for stabilizing all-solid waste filling materials containing dioxin-containing waste incineration fly ash, the details are as follows: the activated cement, aggregate and water reducing agent are mixed evenly with water, and the specific steps are as follows:

[0082] (1) Dry the required raw materials slag, fluorine gypsum, carbide slag, and waste incineration fly ash to a moisture content of 0.01% to 0.1%, and then dry the slag, fluorine gypsum, calcium carbide slag, and waste incineration fly ash by weight percentage on a dry basis Separately grind at 35%, 5%, 10%, and 50% to specific surface areas of 400, 280, 320, and 100m 2 / Kg and mixed in the blender to prepare the cement;

[0083] (2) The weight ratio of cement / aggregate is 1 / 3, the mass fraction of slurry is 76%, and the qualified cemented filling material for mine can be obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com