A preparation method of cemented filling material for mining with resource utilization of cadmium-containing hazardous waste

A hazardous waste and cemented filling technology, which is applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of high cost, large area of follow-up safe landfill, large capacity expansion ratio, etc., to achieve The effect of high cost, large floor area and large capacity increase ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A gelling agent for mines, prepared from the following raw materials in percentage by weight:

[0040] Slag 54%

[0041] Steel slag 35%

[0042] Desulfurization gypsum 11%

[0043] A method for preparing cemented filling materials for mines for co-processing hazardous wastes containing cadmium, characterized in that: the activated cement, aggregates, hazardous wastes containing cadmium, water reducer, and water are mixed uniformly, specifically Proceed as follows:

[0044] (1) Dry the required raw material slag, steel slag, and desulfurized gypsum to a moisture content of 0.01% to 1%, and then separately powder the slag, steel slag, and desulfurized gypsum according to the dry weight percentage of 54%, 35%, and 11%. Grind to a specific surface area of 450m 2 / Kg, 480m 2 / Kg, 360m 2 / Kg mixes in the blender and makes cementing agent;

[0045] (2) Dry the hazardous waste containing cadmium to a moisture content of 0.01% to 1% and grind it to a specific surface ar...

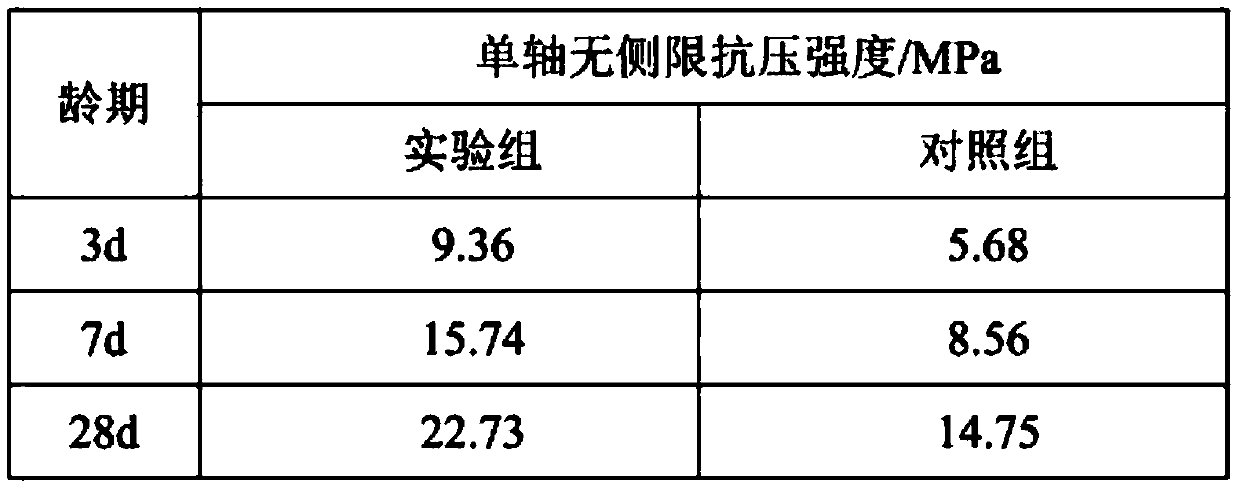

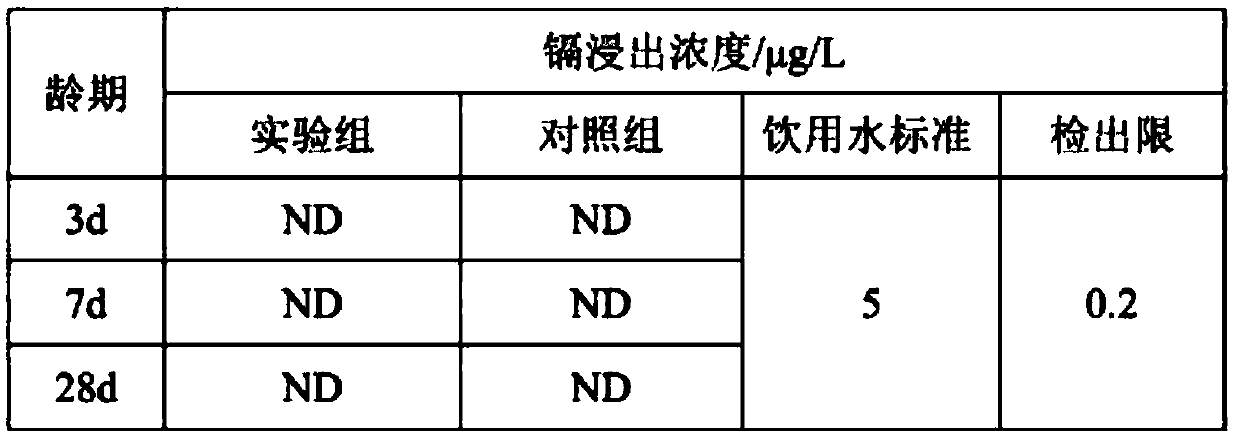

Embodiment 2

[0060] A gelling agent for mines, prepared from the following raw materials in percentage by weight:

[0061]

[0062] A method for preparing cemented filling materials for mines for co-processing hazardous wastes containing cadmium, characterized in that: the activated cement, aggregates, hazardous wastes containing cadmium, water reducer, and water are mixed uniformly, specifically Proceed as follows:

[0063] (1) Dry the required raw material slag, steel slag, and phosphogypsum to a moisture content of 0.01% to 1%, and then separately powder the slag, steel slag, and phosphogypsum at 45%, 20%, and 13% by weight on a dry basis. Grind to a specific surface area of 400m 2 / Kg, 460m 2 / Kg, 360m 2 / Kg, and dried to moisture content of 0.01% ~ 1%, respectively 15% and 7% on a dry basis, and ground to 360m 2 / Kg, 300m 2 / Kg of granulated ferrochromium slag and fly ash are mixed in a mixer to make a cement;

[0064] (2) Dry the hazardous waste containing cadmium to a moi...

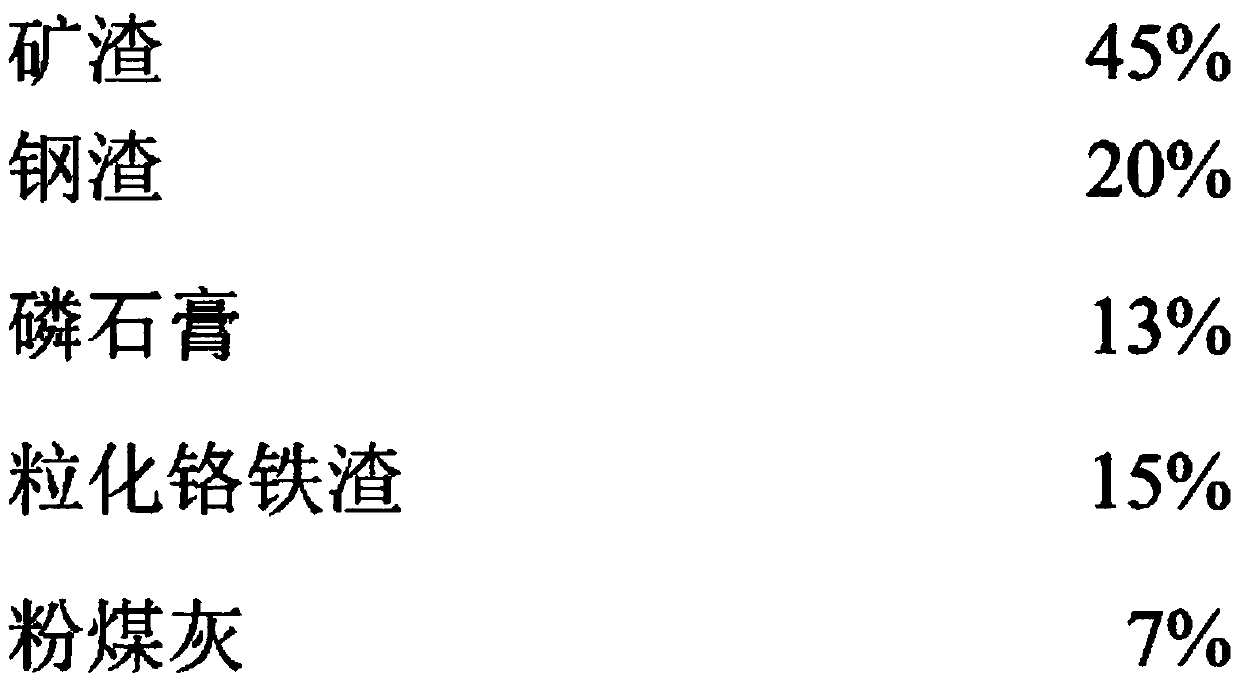

Embodiment 3

[0080] A gelling agent for mines, prepared from the following raw materials in percentage by weight:

[0081]

[0082] A method for preparing cemented filling materials for mines for co-processing hazardous wastes containing cadmium, characterized in that: the activated cement, aggregates, hazardous wastes containing cadmium, water reducer, and water are mixed uniformly, specifically Proceed as follows:

[0083] (1) Dry the required raw material slag, steel slag, desulfurized gypsum, and fluorine gypsum to a moisture content of 0.01% to 1%, and then dry the slag, steel slag, desulfurized gypsum, and fluorine gypsum to 42% and 20% by weight on a dry basis, respectively. %, 8%, 5% are individually ground to a specific surface area of 480m 2 / Kg, 510m 2 / Kg, 330m 2 / Kg, 310m 2 / Kg, and dried to a moisture content of 0.01% to 1%, respectively 15% and 10% on a dry basis, and individually ground to 440m 2 / Kg, 370m 2 / Kg of granulated electric furnace phosphorus slag and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com