Lead-free Bi0.5Na0.5TiO3-based magnetoelectric composite ceramic and preparation method thereof

A technology of magnetoelectric composite and composite ceramics, which is applied in the field of lead-free Bi0.5Na0.5TiO3-based magnetoelectric composite ceramics and its preparation, and can solve the problems of reducing the coupling performance of magnetoelectric materials, adverse magnetoelectric conversion effects, and harm to human health. , to achieve the effect of increasing the magnetic-mechanical-electric coupling performance, excellent environmental coordination, and large polarization strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

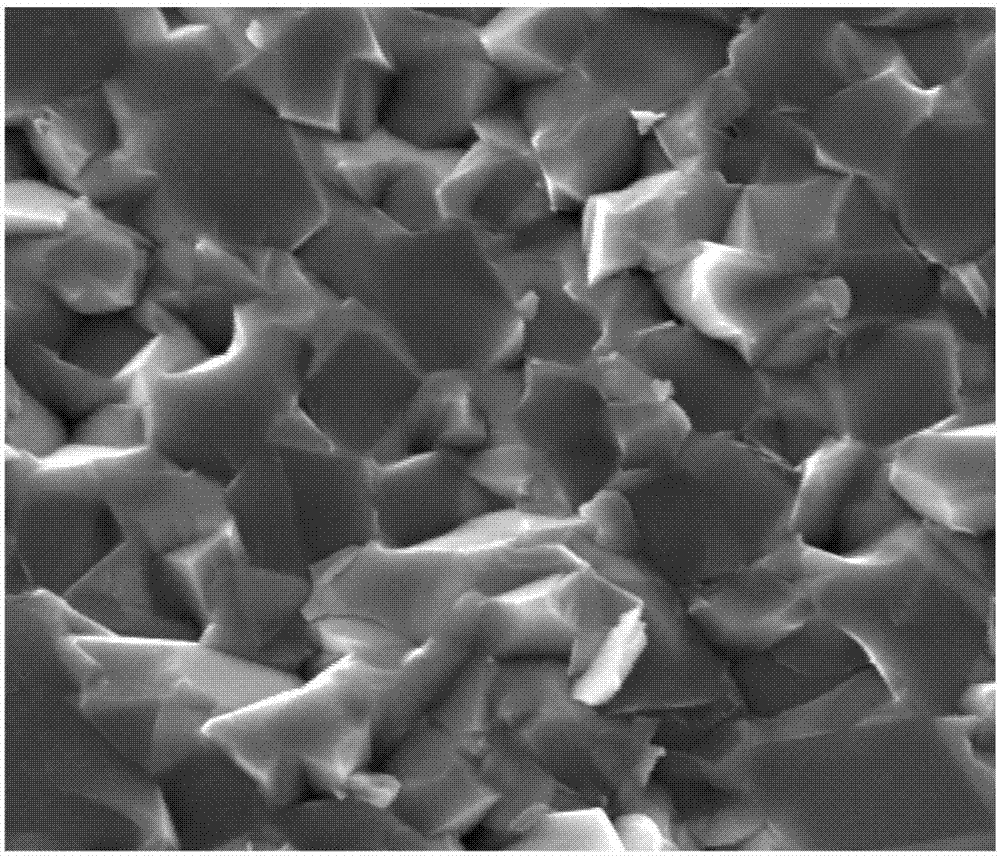

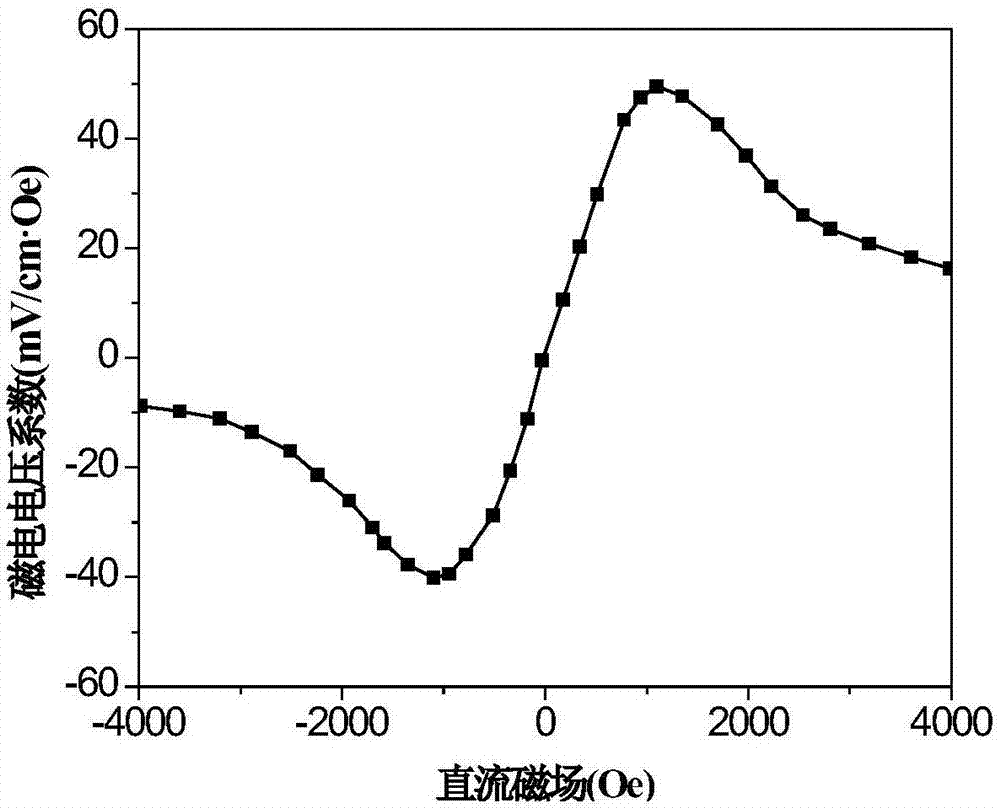

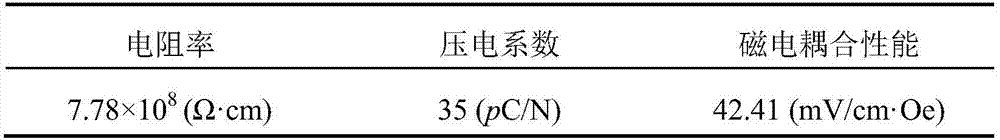

[0028] Lead-free Bi 0.5 Na 0.5 TiO 3 The chemical composition of the base magnetoelectric composite ceramics is: (1-z)[(1-x)Bi 0.5 Na 0.5 TiO 3 -xBi 0.5 K 0.5 TiO 3 ]-zNi 0.8 Zn 0.2 Fe 2 o 4 , where x=0.18, z=0.35. Concrete preparation technological process is as follows:

[0029] 1)Ni 0.8 Zn 0.2 Fe 2 o 4 The preparation of the ferrite ferromagnetic phase: first weigh a certain amount of Ni(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O and Zn(NO 3 ) 2 ·6H 2O was dissolved in an appropriate amount of deionized water, and fully stirred to form a transparent solution; then weighed a certain amount of complexing agent ethylenediaminetetraacetic acid, which was 1.2 times the total molar amount of cations in the composite solution, and added it to the composite solution. solution, and adjust its pH value to 7 with ammonia water, stir evenly until a transparent solution is formed, then place it in a water bath with a constant temperature of 85°C and heat and stir for ...

Embodiment 2

[0037] Lead-free Bi 0.5 Na 0.5 TiO 3 The chemical composition of the base magnetoelectric composite ceramics is: (1-z)[(1-y)Bi 0.5 Na 0.5 TiO 3 -yBaTiO 3 ]-zCoFe 2 o 4 , where y=0.06, z=0.3. Concrete preparation technological process is as follows:

[0038] 1) CoFe 2 o 4 Preparation of ferrite ferromagnetic phase: first weigh a certain amount of Co(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O was dissolved in an appropriate amount of deionized water, and fully stirred to form a transparent solution; then weighed a certain amount of complexing agents ethylenediaminetetraacetic acid and citric acid, and the mixing molar ratio of ethylenediaminetetraacetic acid and citric acid was 3:1 , the total amount of complexing agent is 1.4 times the total molar amount of cations in the composite solution, and it is added to the composite solution, and its pH value is adjusted to 7 with ammonia water, stirred evenly until a transparent solution is formed, and then placed at a con...

Embodiment 3

[0045] Lead-free Bi 0.5 Na 0.5 TiO 3 The chemical composition of the base magnetoelectric composite ceramics is: (1-z)[(1-y)Bi 0.5 Na 0.5 TiO 3 -yBaTiO 3 ]-zNiFe 2 o 4 , where y=0.08, z=0.2. Concrete preparation technological process is as follows:

[0046] 1) NiFe 2 o 4 The preparation of the ferrite ferromagnetic phase: first weigh a certain amount of Ni(NO 3 ) 2 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O was dissolved in an appropriate amount of deionized water, and fully stirred to prepare a transparent solution; then weighed a certain amount of complexing agents ethylenediaminetetraacetic acid and citric acid, and the mixing molar ratio of ethylenediaminetetraacetic acid and citric acid was 4:1 , the total amount of complexing agent is 1.3 times the total molar amount of cations in the composite solution, and it is added to the composite solution, adjusted to pH 7 with ammonia water, stirred evenly until a transparent solution is formed, and then placed at a constant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com