Preparation method of CNTs (Carbon Nanotubes) modified PAN (Polyacrylonitrile) phase change material microcapsule composite thin film

A technology of phase-change microcapsules and phase-change materials, which can be applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of difficult operation, high cost, limited energy saving effect, etc., and achieve fast heat transfer rate and heat storage. Good temperature regulation performance and good specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

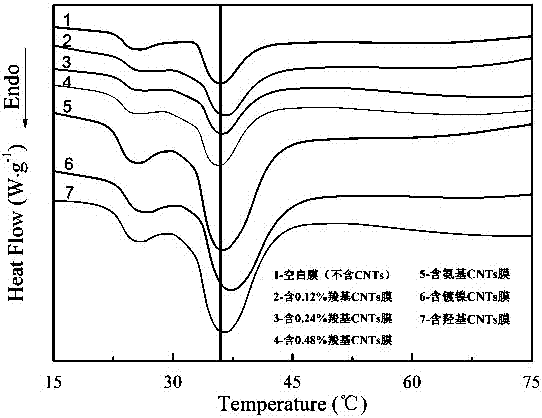

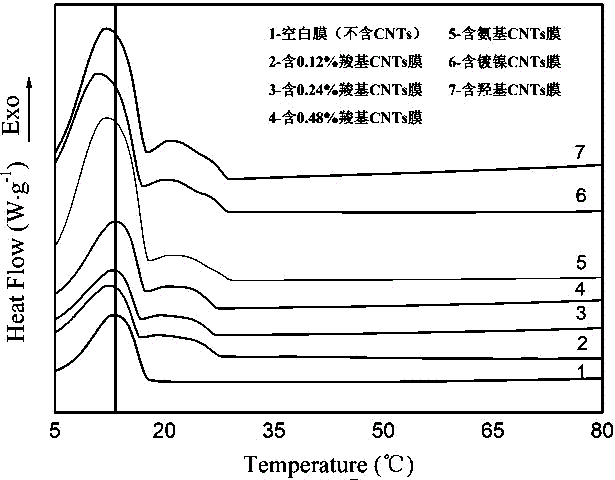

[0035] The invention discloses a preparation method of a CNTs-modified PAN phase-change material microcapsule composite film, which is carried out sequentially according to the following steps:

[0036] Polymers in the method include polyacrylonitrile (PAN), N-methylpyrrolidone, n-nonadecane phase change microcapsules, CNTs and polyvinylpyrrolidone;

[0037] The first step is to pulverize a sufficient amount of PAN powder and dry it in an oven at a constant temperature of 75°C for 12 hours to remove the moisture;

[0038] The second step is to weigh an appropriate amount of N-methylpyrrolidone and add it to the beaker, then weigh 2.4±0.1 grams of n-nonadecane phase-change microcapsules and pour them into the beaker, and ultrasonically disperse them for 30 minutes to make a base liquid; repeat the above actions, Prepare 7 groups of the same base solution, and carry out the experiments of groups 1-7 respectively;

[0039]Add CNTs to the base liquid, and then continue to ultraso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com