Wear resistant self-cleaning photovoltaic glass anti-reflection hydrophobic coating liquid and preparation method thereof

A photovoltaic glass and self-cleaning technology, which is applied in antifouling/underwater coatings, biocide-containing paints, coatings, etc., can solve the problems of poor service life, poor hydrophobic angle of alkali catalysis, high energy consumption, etc., and prevent light transmission Efficiency reduction, easy to keep clean, simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

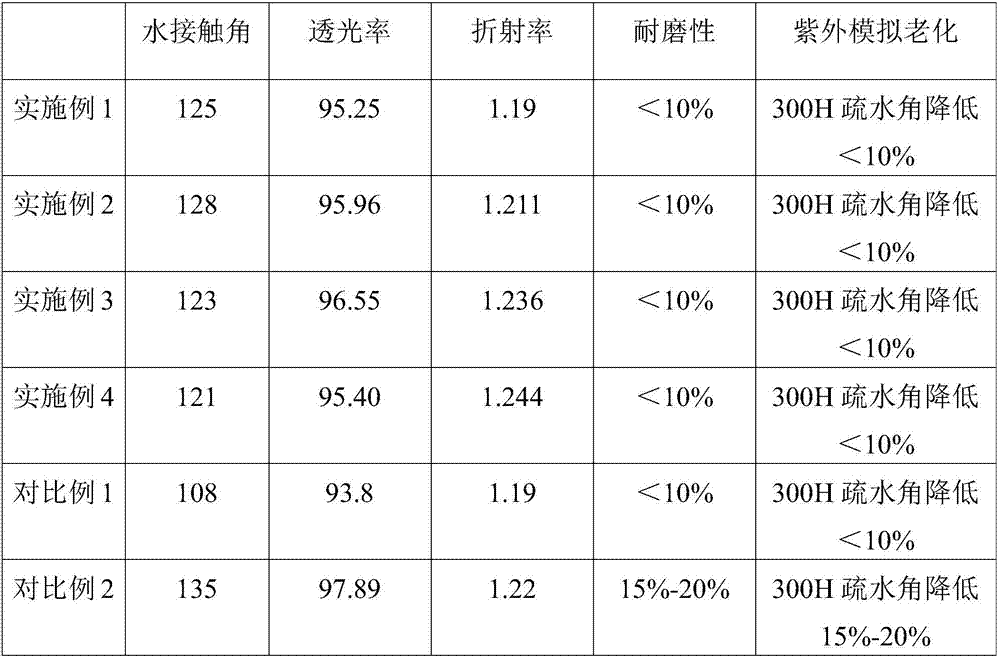

Examples

Embodiment 1

[0027] A: Acid-catalyzed gel: dissolve 3 grams of heptadecanylfluorodecyltrimethoxysilane and 1.5 grams of tetraethyl orthosilicate in 80 grams of ethanol, add 36% hydrochloric acid, adjust the pH to 3, and heat at 50 degrees Celsius for 3 hours to stop Stir, heat to 40°C, vacuum the hydrochloric acid

[0028] B: Alkali-catalyzed gel: 3 grams of heptadecafluorodecyltrimethoxysilane and 1.5 g of tetraethyl orthosilicate were dissolved in 80 grams of ethanol, slowly added 25% ammonia water at 25 degrees Celsius, adjusted to pH 10, and stirred for 5 hours , heated to 40 degrees Celsius, vacuumed to remove ammonia, sealed and aged at room temperature for 7 days

[0029] C: Slowly add 1 volume of base-catalyzed gel to 1 volume of acid-catalyzed gel, stir while adding, and continue stirring for 3 minutes after the addition is complete.

[0030] D: Spray the mixed system on the ultra-white glass, level it naturally, and cure it at room temperature for 24 hours to test

Embodiment 2

[0032] A: Acid-catalyzed gel: Dissolve 3 g of tridecafluorooctyltrimethoxysilane and 1.5 g of tetraethyl orthosilicate in 80 g of ethanol, add 36% hydrochloric acid, adjust the pH to 3, and heat at 50 degrees Celsius for 3 hours to stop Stir, heat to 40°C, vacuum out acetic acid

[0033] B: Alkali-catalyzed gel: 3 grams of heptadecafluorodecyltrimethoxysilane and 1.5 g of tetraethyl orthosilicate were dissolved in 80 grams of ethanol, slowly added 25% ammonia water at 25 degrees Celsius, adjusted to pH 10, and stirred for 5 hours , heated to 40 degrees Celsius, vacuumed to remove ammonia, sealed and aged at room temperature for 7 days

[0034] C: Slowly add 1 volume of base-catalyzed gel to 1 volume of acid-catalyzed gel, stir while adding, and continue stirring for 3 minutes after the addition is complete.

[0035] D: Spray the mixed system on the ultra-clear glass, and cure it at room temperature for 24 hours to test

Embodiment 3

[0037] A: Acid-catalyzed gel: Dissolve 3 grams of heptadecanylfluorodecyltrimethoxysilane and 1.5 grams of tetraethyl orthosilicate in 80 grams of ethanol, add 36% nitric acid, adjust the pH to 3, and heat at 50 degrees Celsius for 3 hours to stop Stir, heat to 40°C, vacuum out acetic acid

[0038] B: Alkali-catalyzed gel: 3 g of tridecafluorooctyltrimethoxysilane and 1.5 g of tetraethyl orthosilicate were dissolved in 80 g of ethanol, slowly added 25% ammonia water at 25 degrees Celsius, adjusted the pH to 10, and stirred for 5 hours , heated to 40 degrees Celsius, vacuumed to remove ammonia, sealed and aged at room temperature for 7 days

[0039] C: Slowly add 1 volume of base-catalyzed gel to 1 volume of acid-catalyzed gel, stir while adding, and continue stirring for 3 minutes after the addition is complete.

[0040] D: Spray the mixed system on the ultra-clear glass, and cure it at room temperature for 24 hours to test

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com