Railway rail surface laser-cladding rust-proof conducting method and apparatus for implementing method

A laser cladding and rail technology, applied in the directions of roads, tracks, laying tracks, etc., can solve problems such as signal false alarms, and achieve the effect of small heat affected zone, high heat conversion efficiency, and improved construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

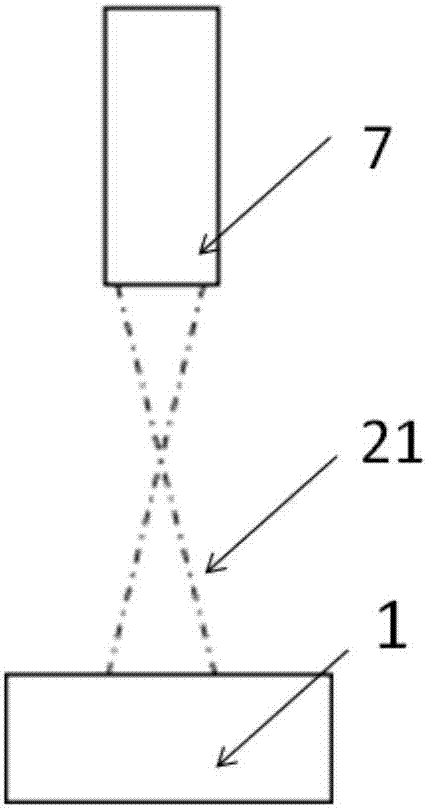

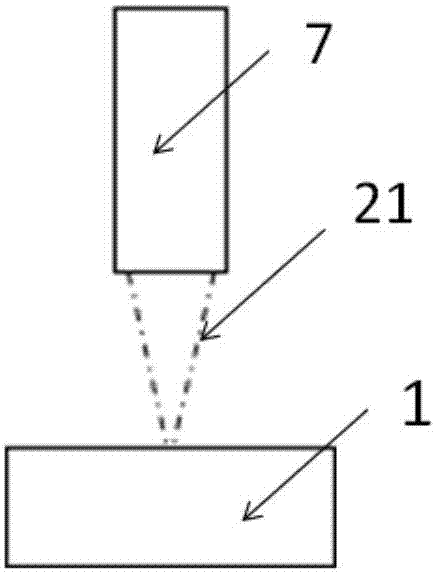

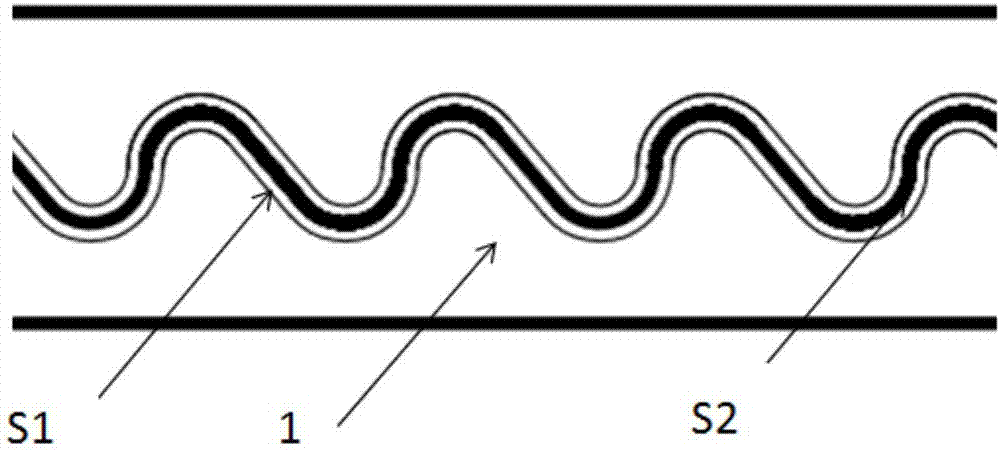

[0042] This embodiment provides a laser cladding anti-rust and conductive method for railway rail rail surface. A high-energy laser is used to clad specific metal powder (nickel) on the surface of the rail to form an S-shaped conductive metal wire. The S wire has good electrical conductivity. , No rust characteristics. In other embodiments, other specific shapes of conductive metal lines, such as non-linear conductive metal lines such as Z-shape, can also be formed.

[0043] The method mainly includes the steps of laser rust removal and laser cladding;

[0044] (1) Laser derusting. The laser irradiates the rail surface of rail 1 along the S path. The irradiation width is 2-5mm. When it is destroyed, an S-shaped path S1 showing the true color of the rail is formed on the surface of rail 1, see image 3 .

[0045] (2) Laser cladding. After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com