Rotary compressor and temperature adjusting device

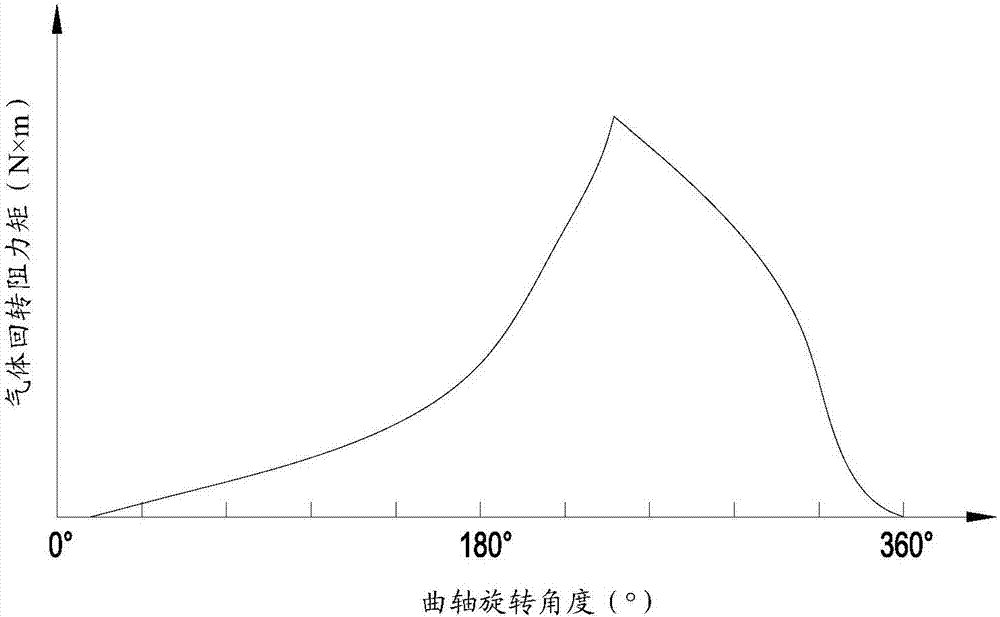

A technology for rotary compressors and compression chambers, which is applied to rotary piston machinery, compressors, rotary piston pumps, etc., can solve problems such as increased control difficulty, noise deterioration, and bus voltage fluctuations in electronic control systems, so as to improve user Experience and eliminate the effect of loud noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

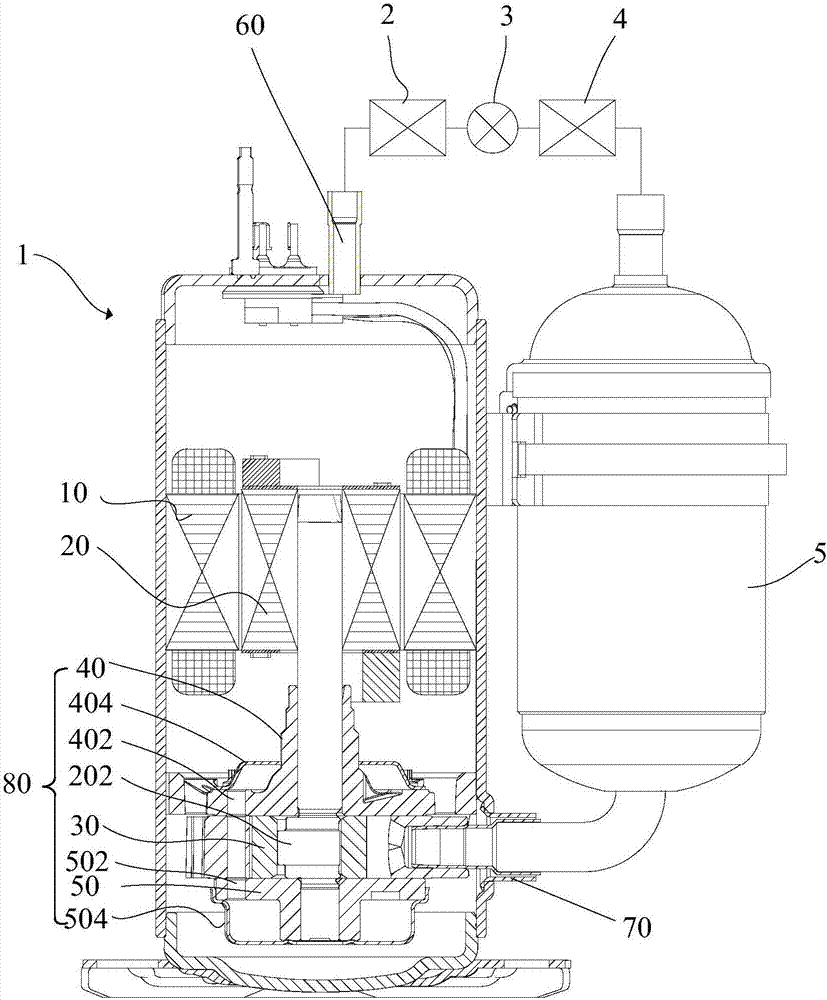

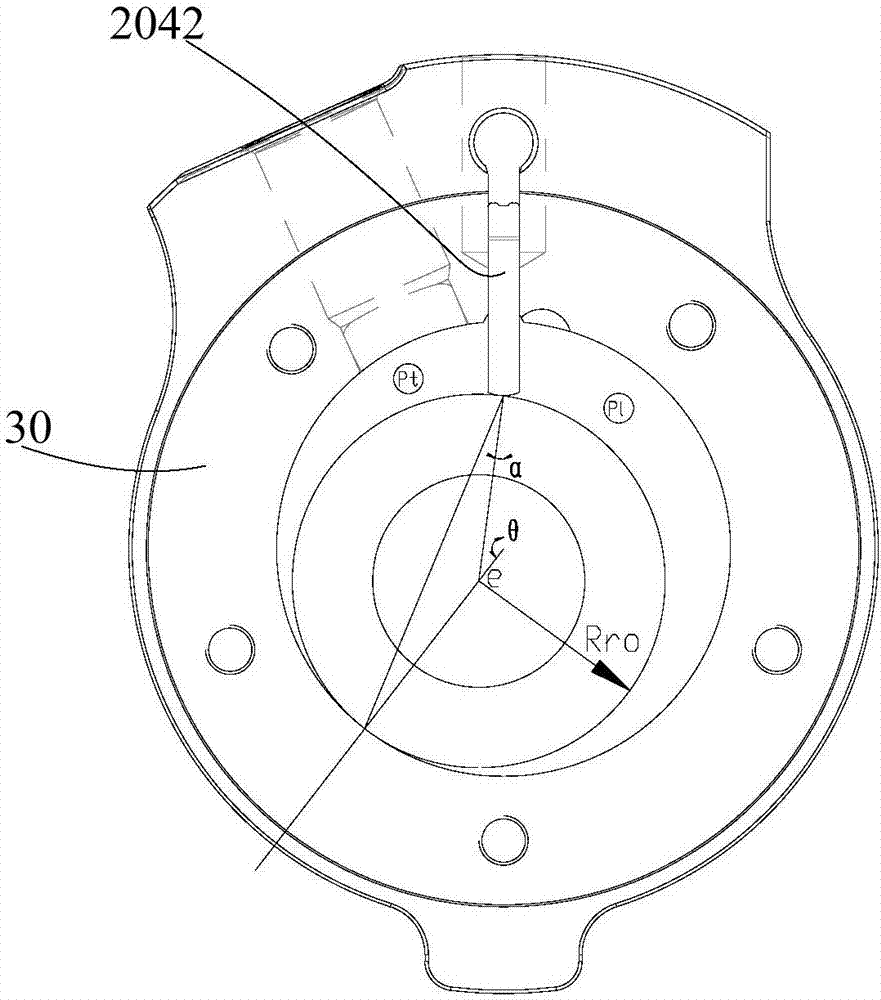

[0070] In this specific example, if Figure 1 to Figure 7 As shown, the casing of the rotary compressor 1 includes a stator 10 and a rotor 20 , and the stator 10 and the rotor 20 are coaxial. The rotary compressor 1 includes a cylinder, and the eccentric section 202 on the crankshaft is located in the cylinder. There are two bearings located on both sides of the cylinder and sleeved on the rotor 20, namely the first bearing 40 and the second bearing 50, the first exhaust structure 402 of the first bearing 40, and the second exhaust structure of the second bearing 50. Structure 502 communicates with the exhaust port of the cylinder. The first bearing 40 is covered with a first muffler 404, and the second bearing 50 is covered with a second muffler 504. The gas from the gas-liquid separator 5 enters the cylinder through the intake pipe 70, and the cylinder processes the gas into high-temperature and high-pressure gas. Discharged from the first exhaust structure 402 and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com