High pressure loss fire grate segment structure device for garbage incinerator

A technology for waste incinerators and grate pieces, which is applied to incinerators, grate, combustion types, etc., can solve problems such as failure to reach the rate of reduction on hot ignition, increase in slag leakage rate of incinerators, partial wear of grate pieces, etc. The effect of tail contact area, improved air intake form, and easy disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

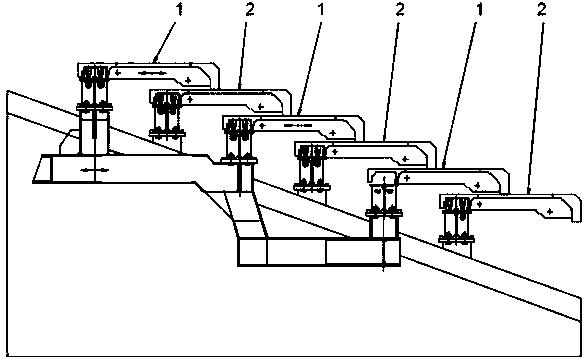

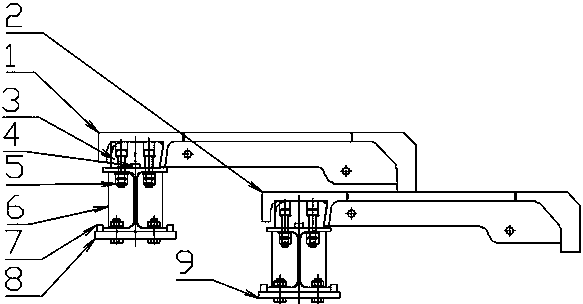

[0035] see figure 1 and figure 2 , the present invention provides a high pressure loss grate structure device for a garbage incinerator, which is mainly composed of a fixed grate 2 and a movable grate 1 .

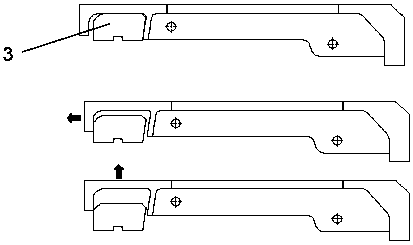

[0036] The fixed grate piece 2 is provided with a grate piece support block 3, a support block stopper 4, a support block support profile steel 6, a profile steel stop block 7 and a fixed grate piece base 9. Supporting block supporting profiled steel 6 and profiled steel block 7 are installed on the fixed fire grate sheet base 9 and are fixed by bolts. The top of the support block support section steel 6 is installed with a fire grate sheet support block 3 and a support block block 4, and is fixed by the support block fixing bolt 5. Each fixed fire grate piece 2 is provided with the double support member installed side by side on the fixed fire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com