Method for preferably selecting silicon material based on XRD (X-ray diffraction) and application thereof

A material, siliceous technology, applied in the field of material quality determination, can solve the problem of time-consuming and laborious, and achieve the effect of reducing energy consumption, strong applicability, and increasing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

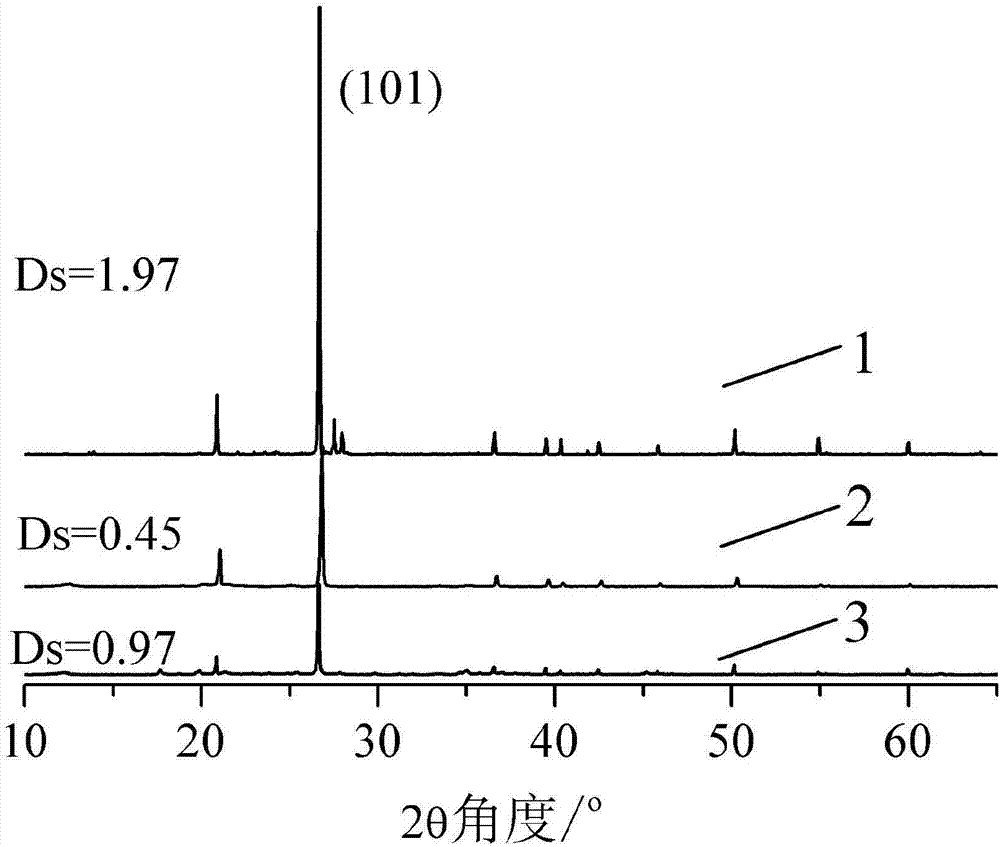

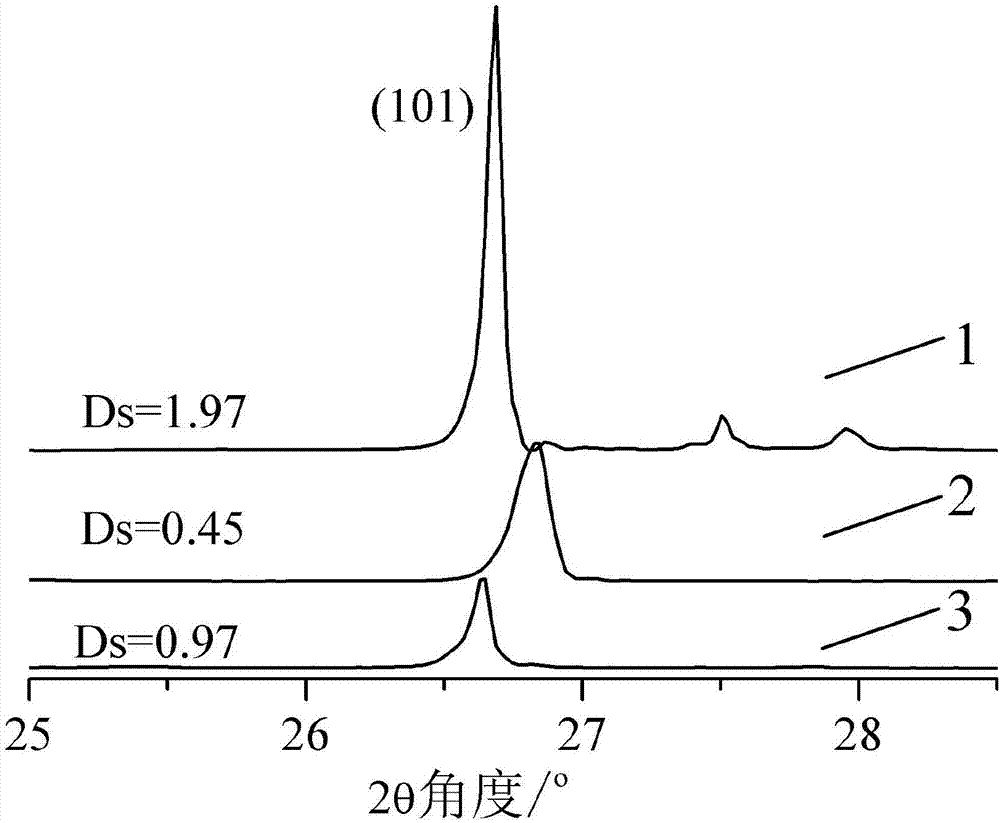

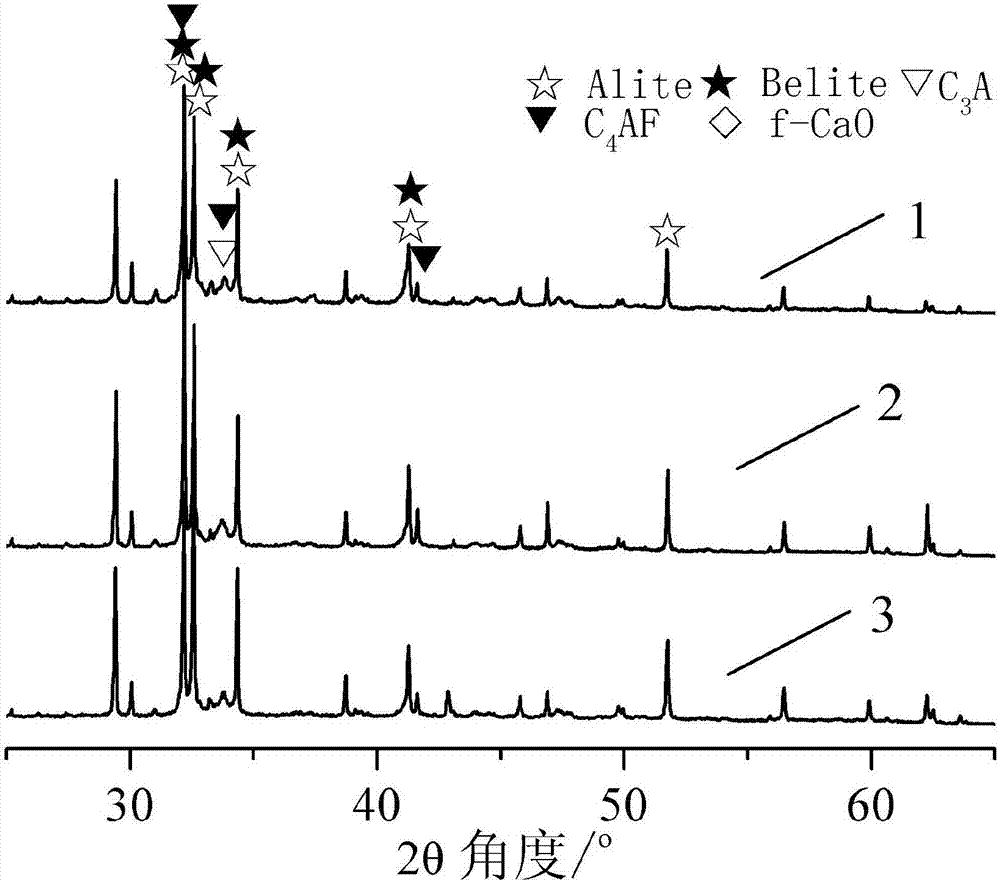

[0049] The chemical compositions of three kinds of siliceous raw materials including quartz sand 1, high silica sandstone 2 and medium silica sandstone 3 are shown in Table 1-1. The raw materials are pulverized and finely ground, and the sieve residue with a particle size of 80 μm is controlled to be less than 10%. By slowly scanning (or increasing instrument power) etc. (the measurement condition of this embodiment is: D8ADVANCE type, X-ray diffractometer (X-ray diffraction, XRD), LynxEye one-dimensional array detector, 40kw, 250mA, Cu Kα 1,2 Diffraction, step size 0.01°, scanning speed 8° / min. ), so that in the XRD diffraction results of all samples, the diffraction peak intensity of the quartz (101) crystal plane (that is, around θ=26.64 degrees) is not less than 10,000 data points. The XRD diffraction patterns of the three siliceous raw materials are shown in figure 1 . First, calculate the ratio R of the absolute intensity of the (101) crystal plane diffraction peak to...

Embodiment 2

[0060] The chemical compositions of the four siliceous raw materials are shown in Table 2-1. Among them, the first mineral processing waste rock 6 and the second mineral processing waste rock 5 are due to SiO 2 The content is low, and it needs to be corrected by adding high-silicon raw materials. In order to avoid the influence caused by the difference in chemical composition, SiO 2 The content of chemical reagents was corrected, and the introduced amounts were 24.5% and 68.7% (mass percentage) of the total siliceous raw materials used respectively. The above-mentioned raw materials are pulverized and finely ground, and the sieve residue with a particle size of 80 μm is controlled to be below 10%. By slowly scanning (or increasing instrument power) etc. (the measuring condition of this embodiment is: D8ADVANCE type, X-ray diffractometer (X-ray diffraction, XRD), LynxEye one-dimensional array detector, 40kw, 250mA, Cu K α 1,2 Diffraction, step size 0.01°, scanning speed 8° / m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com