Preparation method of low-on-resistance high-threshold-value voltage enhancement type GaN device

A technology with high threshold voltage and low on-resistance, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problem of low barrier layer, large square resistance in the p-GaN cap layer area, affecting device conduction characteristics, etc., to achieve the effect of high optimization space, low on-resistance, and reduction of mutual constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

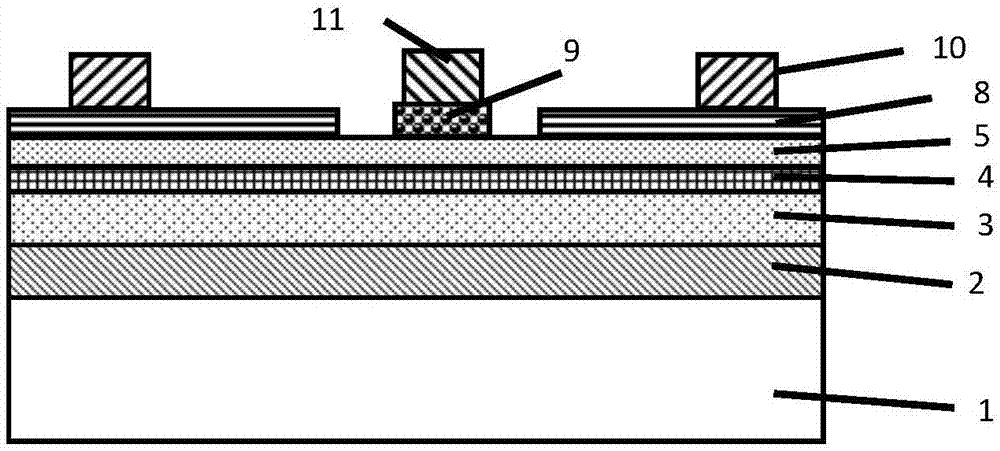

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

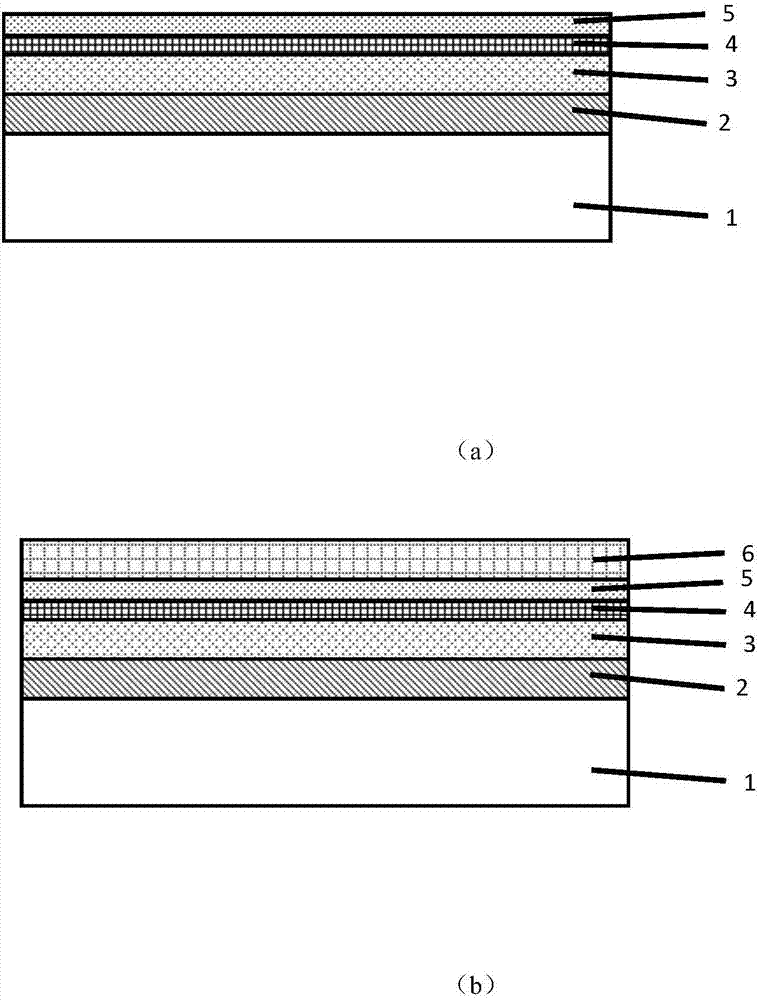

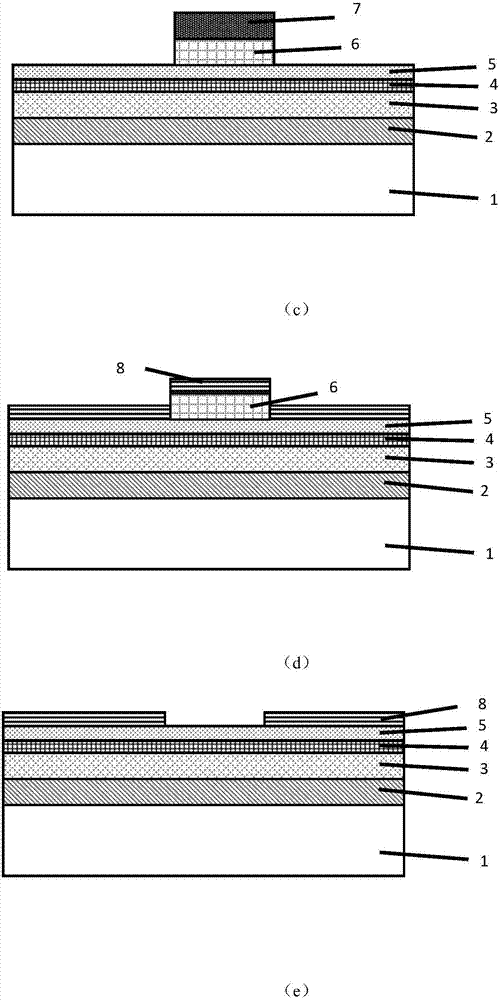

[0023] Such as figure 1 Shown is a schematic diagram of the GaN enhanced device structure with low on-resistance and high threshold voltage according to the present invention, and its preparation method includes growing a full-structure material growth with a buffer layer, a channel layer, an insertion layer, and a barrier layer; the outer channel Preparation of selective growth mask; definition of gate area mask; selective regrowth of outer channel layer structure and removal of mask; preparation of gate area selective growth mask; definition of gate regrowth area; gate area barrier layer re-growth Growth and removal of masks; preparation of ohmic contacts; preparation of gate contacts. Specifically include the following steps:

[0024] (1) On the substrate 1, utilize the epitaxial growth method to epitaxially grow the buff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com