Connecting device for replacing AGC cylinder of rolling mill

A connecting device and rolling mill technology, which is applied to the rolling mill control device, the metal rolling stand, the metal rolling mill stand, etc., can solve the problems of occupying a lot of manpower and equipment, many operation steps, and long time, so as to reduce the maintenance engineering cost, Improve the replacement efficiency and make the effect of convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

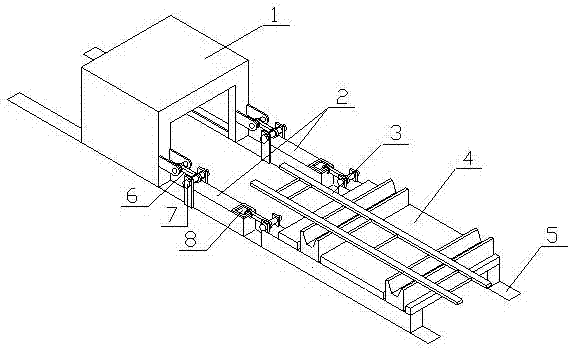

[0030] In the connection device for replacing the AGC cylinder of a rolling mill according to the present invention, in the original design of the rolling mill, hook openings are provided on both sides of the spreader 1, and the hook openings on both sides of the spreader are matched with the hooks on both sides of the carriage 4 to form a spreader. The movable connection with the sliding frame includes two connecting device bodies.

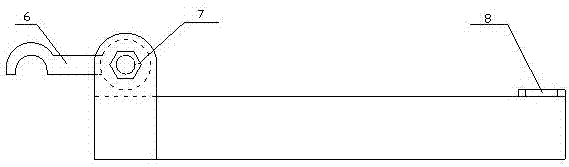

[0031] see now figure 1 , figure 1 It is a structural schematic diagram of the connection device of the embodiment of the present invention. As shown in the figure, the connecting device body is hollow square steel, 1500mm long, 150mm wide, and 150mm high; one end of the cuboid steel block is provided with a 100×100mm square hole, and a 150×150×20mm reinforcing plate is welded above the square hole. A 100×100mm square hole is opened at the same position on the reinforcing plate, and the two sides of the other end are solidly welded to the end p...

Embodiment 2

[0043] In this embodiment, except that the main body of the connection device is assembled and welded by steel plates, the others are the same as in Embodiment 1.

[0044] The present invention has substantive features and significant technical progress. The use value of the connecting device for the replacement of the AGC cylinder of the rolling mill of the present invention is that when the step pad is placed on the carriage in the third step, the step pad will be partially stretched. Out of the sliding frame, the hook on the blocking sliding frame is connected with the special spreader for the AGC cylinder, and the fourth step operation has to be carried out. By adopting the connecting device used for the replacement of the AGC cylinder of the rolling mill to connect the carriage with the special spreader, the fourth step is omitted, and the time for reversing the roll-changing cart is reduced once, and the rolling speed of the roll-changing cart is slow. The time for hoist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com