Internal supporting and heat dissipation device for welding of thin-walled half pipe and using method of the internal supporting and heat dissipation device

A cooling device and a half-edge technology, applied in welding equipment, welding accessories, laser welding equipment, etc., can solve problems such as low yield, many weld defects, and large welding deformation, so as to reduce workload, increase welding current, reduce The effect of small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

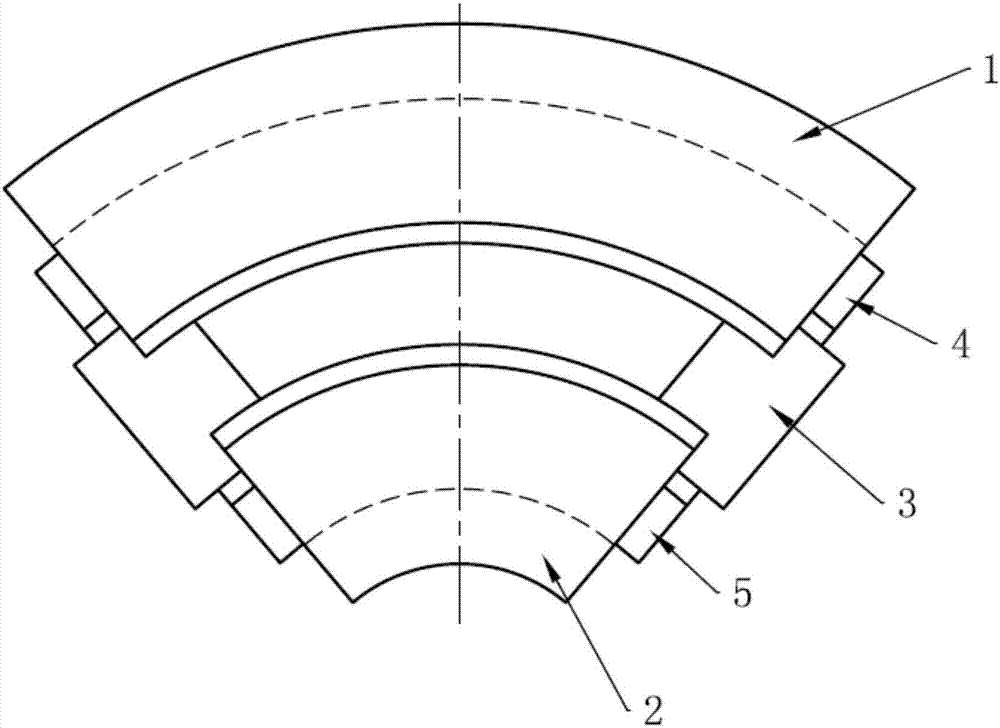

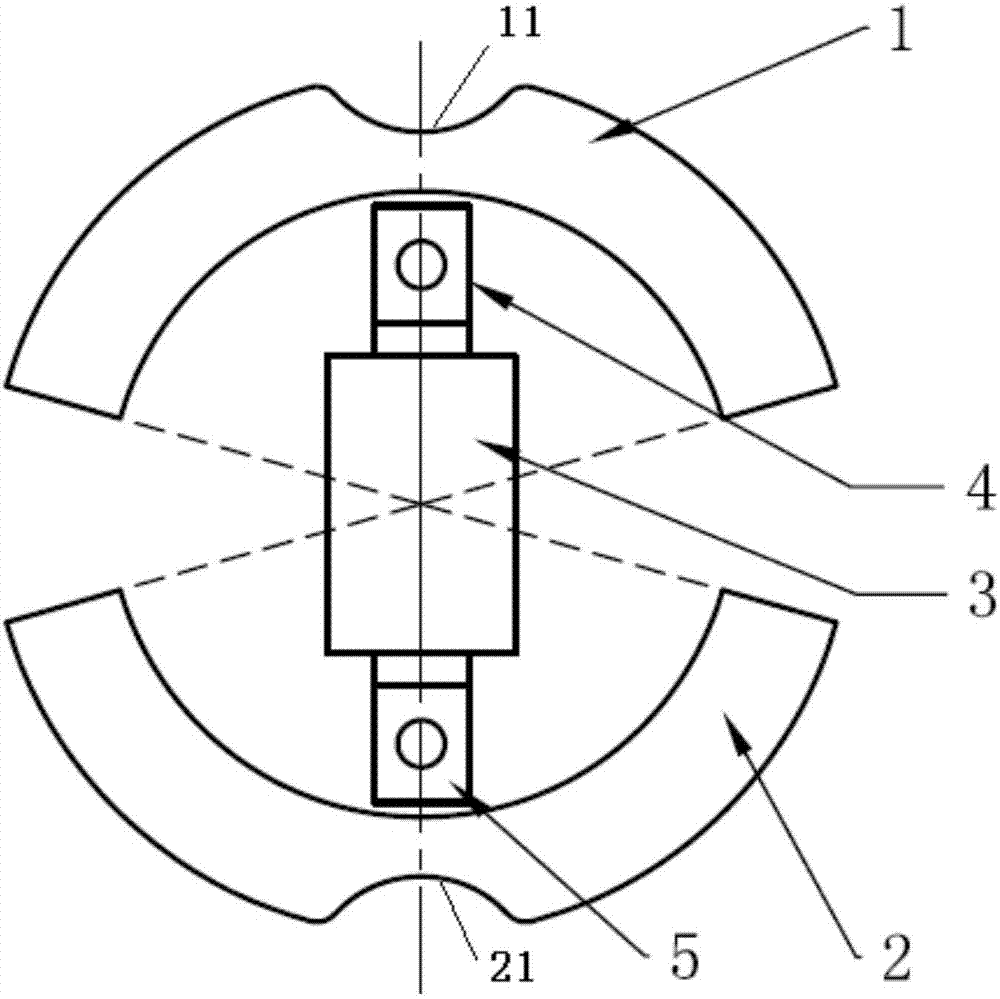

[0020] The following will combine Figure 1 ~ Figure 2 A further detailed description will be made on the inner supporting heat dissipation device for welding thin-walled half-side pipes of the present invention and its application method.

[0021] figure 1 Shown is the front view of the inner supporting cooling device for welding of thin-walled half-side pipes according to the preferred embodiment of the present invention; figure 2 Shown is a side view of an inner support heat sink for welding thin-walled half-side pipes according to a preferred embodiment of the present invention.

[0022] see figure 1 and figure 2 , the inner support cooling device for thin-walled half-side pipe welding includes an upper backing plate 1, a lower backing plate 2, a screw sleeve 3, a first rotating screw 4 and a second rotating screw 5;

[0023] Both ends of the screw sleeve 3 are threadedly connected with the first rotary screw 4 and the second rotary screw 5 respectively;

[0024] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com