Method for operating blast furnace

一种高炉操作、一方的技术,应用在高炉、高炉细节、高炉零部件等方向,能够解决燃烧效率降低、喷枪堵塞、喷枪前端破裂等问题,达到排出CO2减少、燃烧效率提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

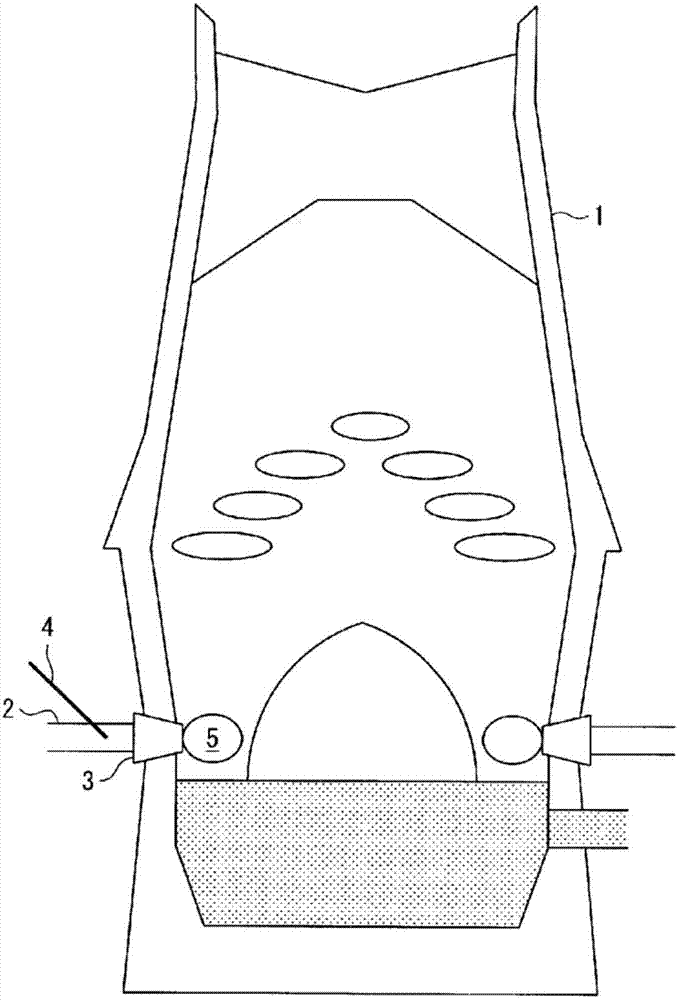

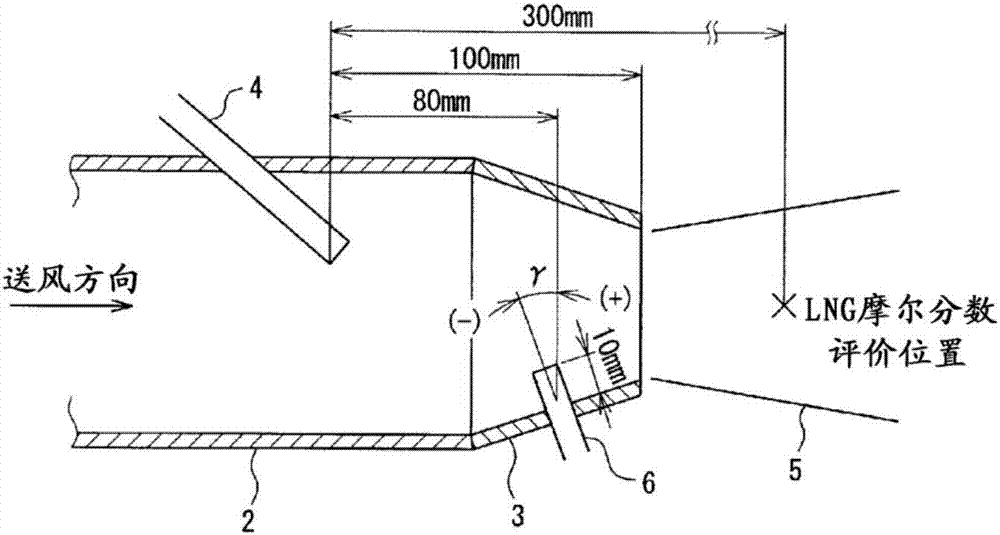

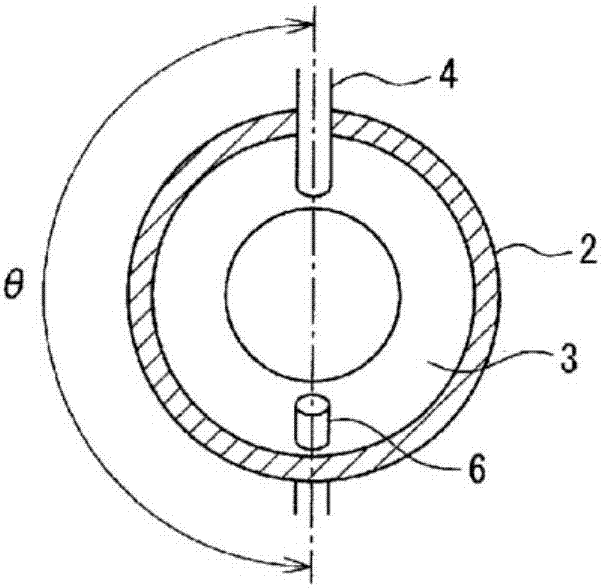

[0024] Next, one embodiment of the blast furnace operating method of the present invention will be described with reference to the drawings. figure 1 It is an overall view of a blast furnace to which the blast furnace operating method of this embodiment is applied. As shown in the figure, an air blowing pipe 2 for sending hot air is connected to a tuyere 3 of a blast furnace 1, and a spray gun 4 is installed so as to pass through the air blowing pipe 2 . Hot air uses air. In the coke accumulation layer in front of the tuyere 3 in the direction of hot air conveyance, there is a combustion space called the swirl zone 5, and in this combustion space, iron ore is mainly reduced, that is, pig iron is produced. In the figure, only one spray gun 4 is inserted into the air supply pipe 2 on the left side of the drawing, but it is well known that the set spray gun can be inserted in any of the air supply pipe 2 and the tuyere 3 arranged in a circumferential shape along the furnace wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com