Flue gas denitrification modularized control device

A modular control and denitration technology, applied in electrical program control, program control in sequence/logic controllers, gas treatment, etc., can solve the problems of low electric shock protection level, waste of resources, long installation period, etc. Low level of electric shock protection, reduced waste of cable resources, scientific and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

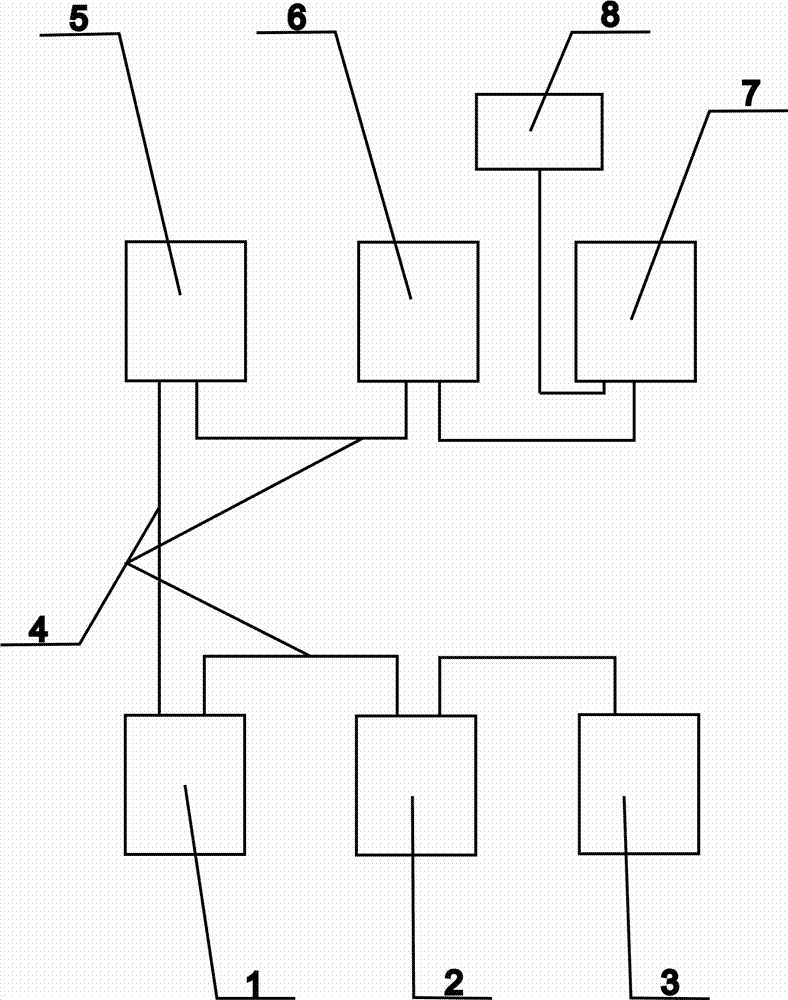

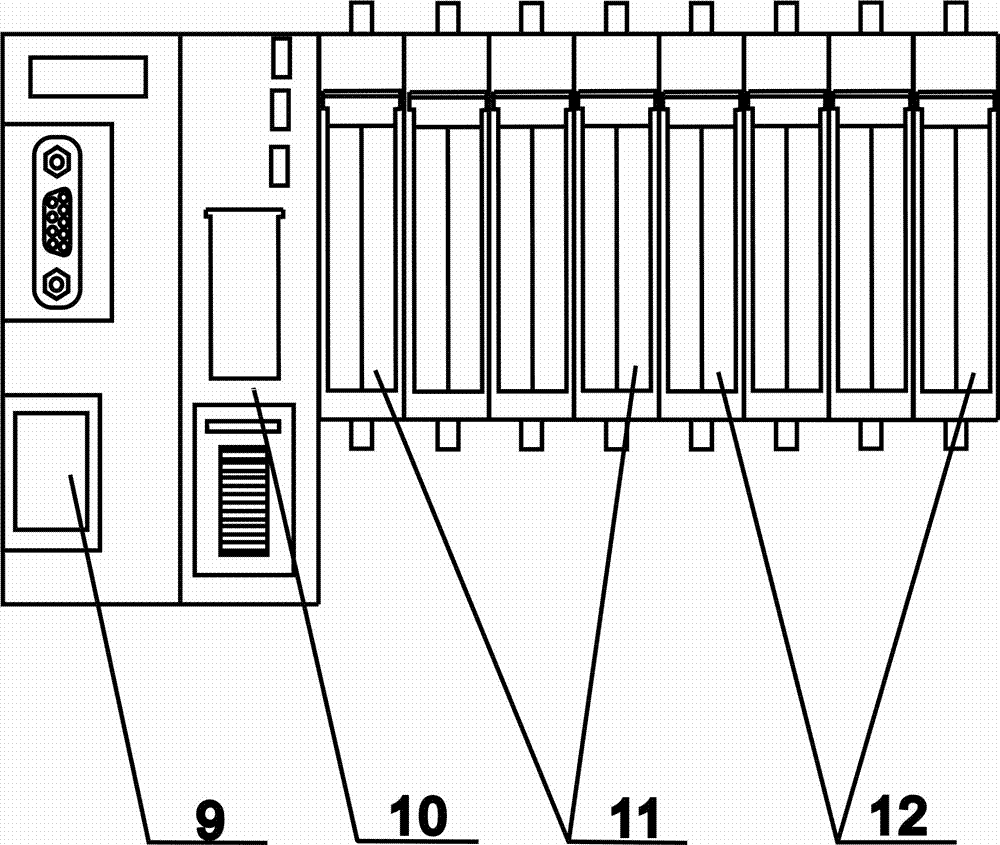

[0025] As shown in the figure, a flue gas denitrification modular control device includes an ammonia water filling and storage unit 1, an ammonia water delivery unit 2, a soft water delivery unit 3, and an open field standard bus 4; the ammonia water filling and storage unit 1 is set in At the bottom left position, from left to right, there are ammonia water delivery unit 2 and soft water delivery unit 3 respectively, ammonia water filling and storage unit 1, ammonia water delivery unit 2 and soft water delivery unit 3 are connected by open field standard bus 4 ; At the left side of the top, there are left mixed distribution unit 5 and right mixed distribution unit 6, and a control management unit 7 is arranged on the right side of the left mixed distribution unit 5 and the right mixed distribution unit 6, and on the left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com