Coke dry quenching boiler economizer serpentine pipe in-place installation lifting device and use method thereof

A technology of serpentine tubes and economizers, applied in the field of spreaders, can solve the problems of inconvenient installation of serpentine tubes for CDQ boiler economizers, complicated peripheral equipment of economizers, excessive dismantling and restoration workload, etc., to prevent The effects of unlucky damage, reduced engineering cost, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

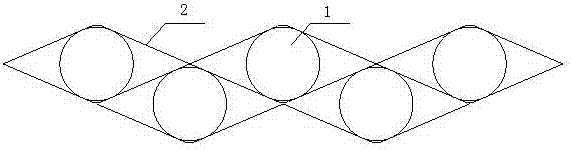

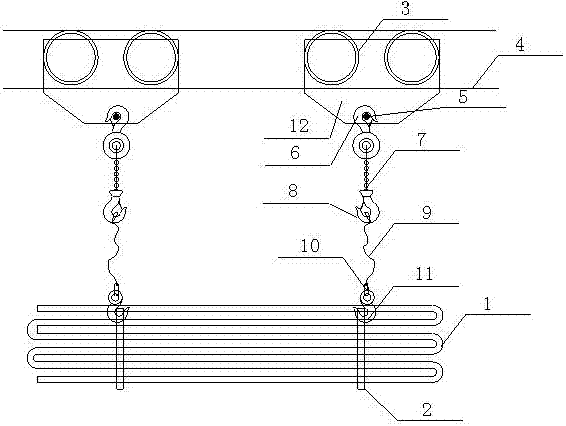

[0035] The serpentine tube of the CDQ boiler economizer of the present invention is installed in place, and includes a rail, a pulley hanger, a chain hoist 7 and a diamond-shaped bracket 2 .

[0036] see now figure 1 and figure 2 , figure 1 It is a schematic structural diagram of the serpentine tube in the embodiment of the present invention being clamped in a diamond-shaped bracket, figure 2 It is a schematic diagram of the use state of the serpentine tube in-position spreader according to the embodiment of the present invention. As shown in the figure, the track is a section of I-beam 4, and the I-beam is horizontally erected above the installation position of the serpentine tube of the economizer of the CDQ boiler.

[0037] The pulley hanger is provided with two side plates 12, the upper parts of the two side plates are each provided with two pulleys 3, the middle parts of the two side plates are horizontally connected to each other by solid welding, and the lower part...

Embodiment 2

[0040] A method for using a spreader for installing an economizer serpentine tube in a CDQ boiler, which is characterized by comprising the following steps:

[0041] a. The track is stably and firmly erected horizontally above the installation position of the economizer serpentine tube of the CDQ boiler, which is convenient for hoisting the economizer serpentine tube and moving the economizer serpentine tube on the track;

[0042] b. The serpentine tube of the economizer of the CDQ boiler is installed in place. The spreader itself is installed. After the pulley hanger, the chain hoist and the sling are connected, the two pulley hangers are matched with each other and are installed on the I-beam. 4 on;

[0043] c. Use two diamond-shaped brackets to be movably clamped at both ends of the serpentine tube, so that the two pulley hangers cooperate with each other to lift the diamond-shaped bracket with a hand chain hoist, and the third hook below the hand chain hoist hangs the snak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com