Method for passivating black phosphorus nanometer materials

A technology of nanomaterials and black phosphorus, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve problems such as high cost, complicated method process, poor passivation effect, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In the present embodiment, the purity specifications of the raw materials used are respectively: Zn(CH 3 COO) 2 (99.9+%), KOH particles (85%), deionized water (R=16.2MΩ), chloroform (chromatographically pure), N-methylpyrrolidone (99.9%).

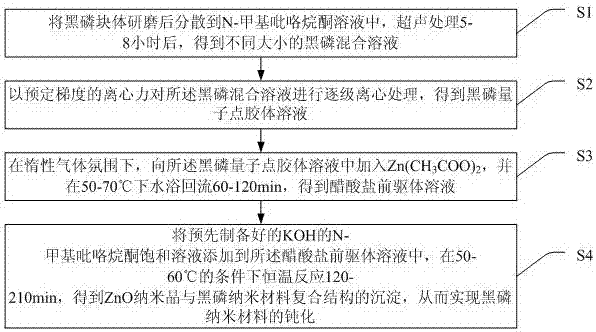

[0048] (1) Grind 5 mg of black phosphorus blocks and disperse them in 20 ml of N-methylpyrrolidone solution, and ultrasonicate for 6 hours to obtain a mixed solution of black phosphorus with different layers;

[0049] (2) The obtained mixed solution is mixed with a certain gradient, 70×g, 278×g, 1112×g, 2503×g, 6953×g, 13628×g and 17800×g (g=9.80m / s 2 ) centrifugal force to carry out stepwise centrifugation to obtain black phosphorus quantum dot colloidal solution;

[0050] (3) 47.58mg Zn(CH 3 COO) 2 Dissolve in 10ml of black phosphorus quantum dot colloidal solution, feed nitrogen into the solution, make the whole reaction in a nitrogen atmosphere, and reflux in a water bath at 60°C for 60 minutes simultaneously to obtain Zn(CH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com