Gel cellulose compound film and preparation method thereof

A technology of gelling cellulose and cellulose film, which is applied in the field of composite materials, can solve the problems of low mechanical strength of cellulose materials, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

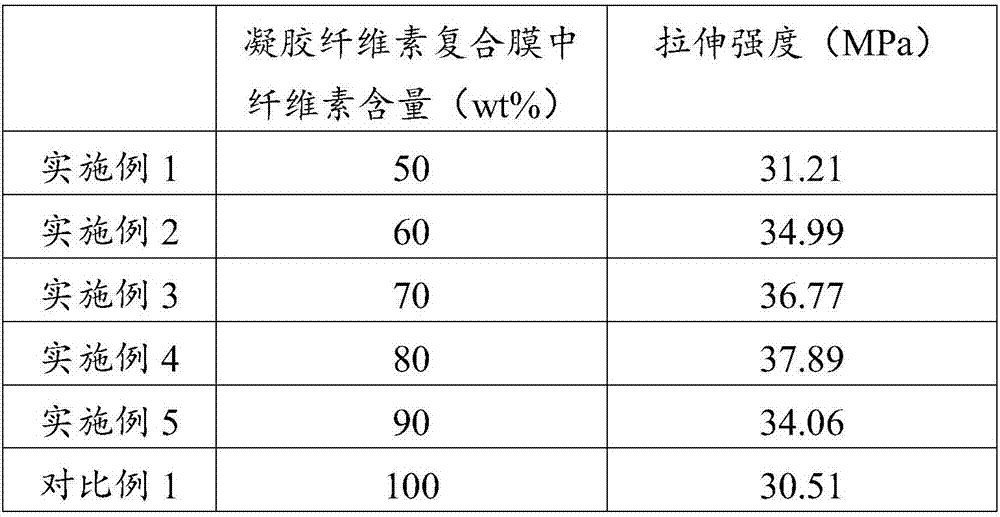

Examples

preparation example Construction

[0028] The invention provides a kind of preparation method of gel cellulose composite membrane, comprises the following steps:

[0029] 1) Dissolving cellulose in an alkali solution to obtain a cellulose solution;

[0030] 2) performing defoaming treatment on the cellulose solution to obtain a defoamed cellulose solution;

[0031] 3) forming a film of the defoamed cellulose solution on the substrate to obtain a wet cellulose film;

[0032] 4) coagulating the wet fiber membrane in a coagulation bath to obtain a cellulose gel membrane;

[0033] 5) freeze-drying the cellulose gel film to obtain a solid cellulose film;

[0034] 6) The solid cellulose membrane is loaded with PHBH in a PHBH solution to obtain a PHBH-cellulose composite membrane, and the PHBH solution is a mixture of poly(3-hydroxybutyrate-3-hydroxyhexanoate) and an organic solvent liquid;

[0035] 7) Carrying out hot-pressing treatment on the PHBH-cellulose composite membrane to obtain a gelled cellulose composi...

Embodiment 1

[0069] (1) Prepare a mixed aqueous solution with a sodium hydroxide content of 7wt% and a urea content of 12wt%. Dissolve 3g of cotton cellulose in 97g of a mixed aqueous solution, freeze for 4 hours at -20°C and mechanically stir until the cellulose Dissolve completely, obtain the cellulose solution that concentration is 3wt%;

[0070] (2) centrifuging the cellulose solution to obtain a defoamed cellulose solution;

[0071] (3) Pour the obtained degassed cellulose solution evenly on a glass plate, and place it horizontally for 30 minutes to obtain a wet cellulose film with a thickness of 70 μm;

[0072] (4) taking out the obtained wet cellulose film after coagulating in a methanol coagulation bath for 30min to obtain a cellulose gel film;

[0073] (5) Pre-freeze the cellulose gel film in a refrigerator at -20°C for 10 hours, freeze it in a freeze dryer at -55°C for 10 hours, and keep the temperature and humidity at 30°C and 65% for 4 hours to obtain solid fibers plain film;...

Embodiment 2

[0077] (1) Prepare a mixed aqueous solution with a sodium hydroxide content of 5wt% and a urea content of 10wt%. Dissolve 6g of wood pulp cellulose in 94g of a mixed aqueous solution, freeze at -10°C for 6h, and mechanically stir until the fibers The element dissolves completely, and obtaining concentration is the cellulose solution of 6wt%;

[0078] (2) centrifuging the cellulose solution to obtain a defoamed cellulose solution;

[0079] (3) Pour the obtained degassed cellulose solution evenly on a glass plate, and place it horizontally for 60 minutes to obtain a wet cellulose film with a thickness of 40 μm;

[0080] (4) taking out the obtained wet cellulose film to obtain the cellulose gel film after coagulating in a methanol aqueous coagulation bath for 90 min;

[0081] (5) Pre-freeze the cellulose gel film in a refrigerator at -10°C for 15 hours, freeze it in a freeze dryer at -60°C for 15 hours, and keep the temperature and humidity at 25°C and 60% for 8 hours to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com