PET/PE alloy sheet and preparation method thereof

A technology of alloy sheet and compatibilizer, which is applied in the field of material processing, can solve the problems that the mechanical properties of PET/PE sheet products are difficult to achieve and obtain, and achieve the effect of being suitable for large-scale production, low cost, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

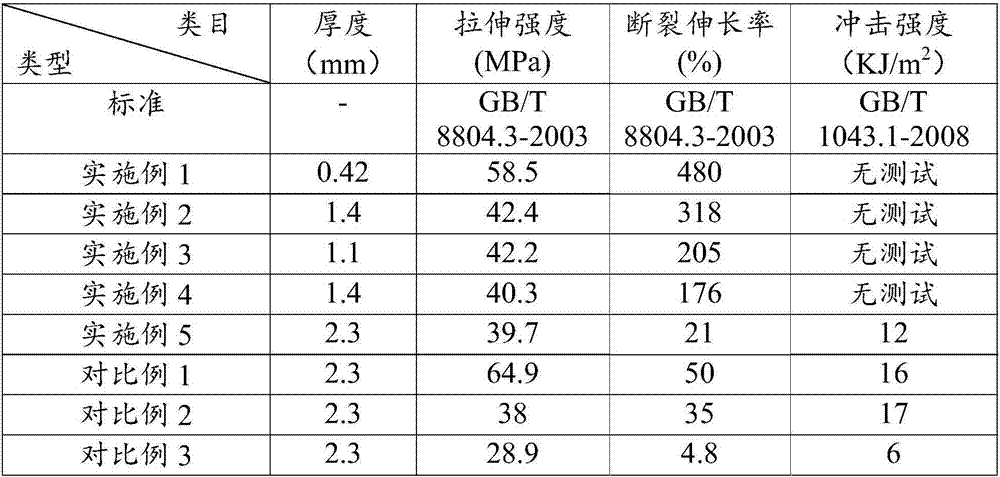

Examples

preparation example Construction

[0059] The above-mentioned preparation method of a PET / PE alloy sheet comprises blending PET, PE and a compatibilizer in proportion, melt extruding, and roll forming to obtain a PET / PE alloy sheet.

[0060] The preparation method of the PET / PE alloy sheet of the invention has simple process, does not need to dry the PET material, has low cost, and is suitable for large-scale production.

[0061] In a preferred embodiment of the present invention, the stirring speed of the blending is 190-210 r / min, preferably 200 r / min.

[0062] In a preferred embodiment of the present invention, the blending time is 4-6 minutes, preferably 5 minutes.

[0063] Adopting a specific blending speed and time can help promote the full and uniform mixing of PET, PE and compatibilizer, promote the compatibility of PET and PE in the subsequent melt extrusion process, and further improve the mechanical properties of the obtained PET / PE alloy sheet.

[0064] The present invention has no special requirem...

Embodiment 1

[0075] A preparation method of a PET / PE alloy sheet, comprising the steps of:

[0076] (1) Take 70 parts of commercially available PET (manufactured by Hainan Yisheng Petrochemical Co., Ltd.), 10 parts of commercially available LLDPE (the brand is JL210, produced by South Korea SK Group) and 1 part of commercially available MAH in terms of parts by mass. Branch EVA compatibilizer (manufacturer is Nanjing Sutai Polymer Technology Co., Ltd.);

[0077] (2) Pass PET, PE and compatibilizer through a high-speed mixer, and stir and mix for 6 minutes at room temperature at a speed of 190r / min;

[0078] (3) Melting and extruding the mixture obtained in step (2) through a twin-screw extruder, wherein the barrel temperature is 180°C, 210°C, 240°C, 260°C, 260°C, and the die head temperature is 260°C;

[0079] (4) The PET / PE alloy sheet is obtained by roll forming with a three-roll calender at a traction speed of 10 mm / min.

Embodiment 2

[0081] A preparation method of a PET / PE alloy sheet, comprising the steps of:

[0082] (1) Take 90 parts of commercially available PET (manufactured by Hainan Yisheng Petrochemical Co., Ltd.), 30 parts of commercially available HDPE (the brand is 5000S, produced by China National Petroleum Corporation) and 5 parts of commercially available PET in terms of mass parts. Sell GMA grafted POE compatibilizer (manufactured by Suzhou Yasai Plastic Chemical Co., Ltd.);

[0083] (2) Pass PET, PE and compatibilizer through high-speed mixer, at room temperature, under the rotating speed of 210r / min, stir and mix 4;

[0084] (3) Melting and extruding the mixture obtained in step (2) through a twin-screw extruder, wherein the barrel temperature is 190°C, 230°C, 260°C, 270°C, 270°C, and the die head temperature is 270°C;

[0085] (4) The PET / PE alloy sheet is obtained by roll forming with a three-roll calender at a traction speed of 30 mm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com