Production technology of cationic polyester and cotton blended yarn

A cationic polyester, production technology, applied in the direction of yarn, textiles, papermaking, fiber treatment, etc., can solve the problems of insufficient dyeing ability of polyester, achieve the effect of improving temperature and hand feeling, less hairiness, and overcoming dyeing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Raw materials: 65% 1.56dtex×38mm cationic polyester and 35% cotton. It can be treated before spinning. According to the test: it is enough to humidify before packing, but it must be stacked for a certain period of time, generally not less than 24 hours, so that the moisture can penetrate evenly. In addition, the humidity control should be based on the principle of gradually dehumidifying. The blowing process is controlled at about 65%-70%, the combing process is controlled at about 60%-65%, and the eddy current spinning process is controlled at about 50%.

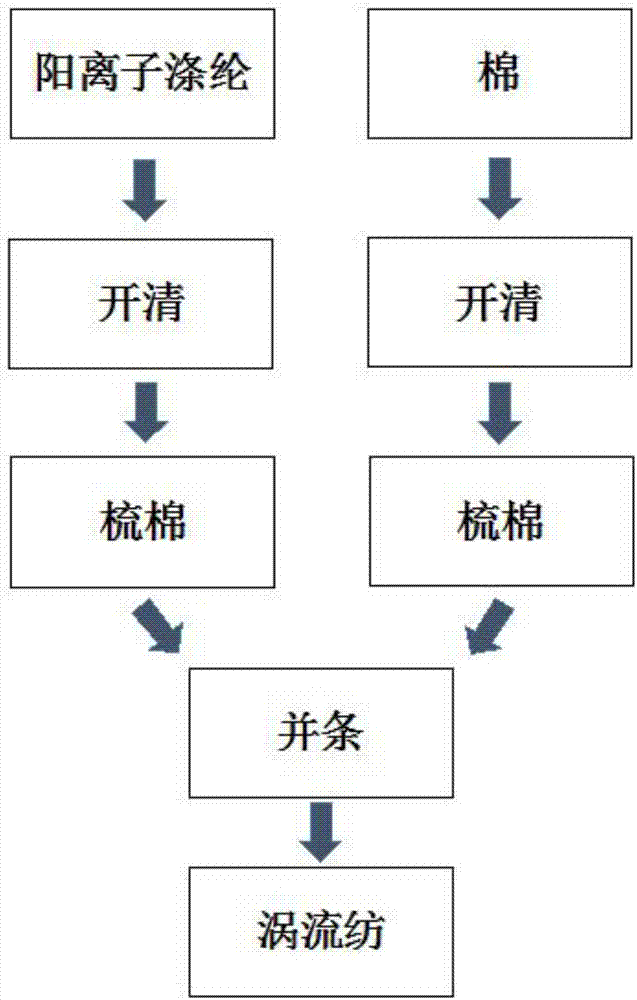

[0020] 2. Spinning process flow: FA002A automatic plucking machine → FA022 multi-compartment blending machine → FA106A cotton opener → FA046A vibrating cotton box feeder → A076F single hand lapping machine → FA224B carding machine → HSD961 drawing frame Machine (one parallel, two parallel)→TD03-600 draw frame (three parallel)→MVS861 vortex spinning machine.

[0021] 3. The technical points of each process.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com