Projector curtain and preparation method thereof

A production method and projector technology, applied in chemical instruments and methods, instruments, fibers affecting crease behavior, etc., can solve the problems of affecting viewing effect, intolerant of dirt, short service life, etc., and achieve dirt resistance and wrinkle resistance. Excellent parameters, good washing and stain resistance, and the effect of improving wrinkle recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

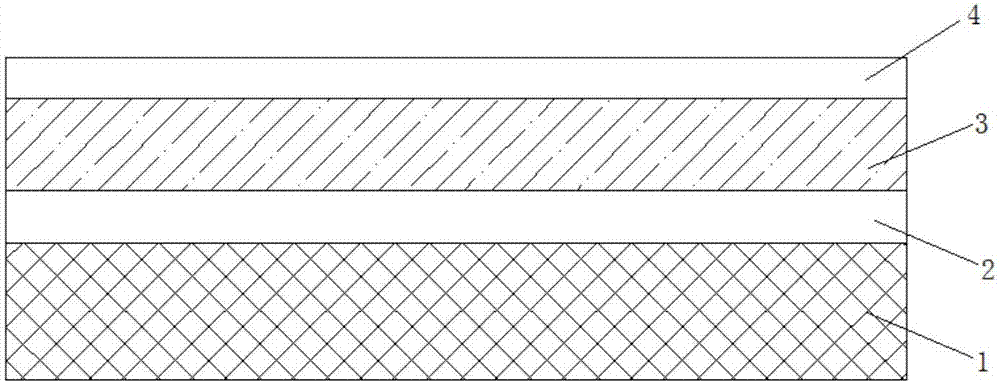

[0024] A projector screen provided in this embodiment is made by curing the base layer 1, the adhesive layer 2, and the reflective layer 3 by hot pressing and then coating a silicone protective layer 4, such as figure 1 shown.

[0025] The above-mentioned basic bottom layer is a multi-axial woven fabric layer soaked with the first immersion liquid; the first immersion liquid is a resin composition, and the above-mentioned resin composition includes 100 parts of polyurethane resin, 0.5 parts of catalyst, 25 parts of soaking agent, 0.6 parts of coupling agent, 0.6 parts of UV absorber, 5 parts of flame retardant, 18 parts of defoaming agent and 25 parts of silicone fabric finishing agent, and 32 parts of curing agent. The second immersion solution is a chitosan solution with a concentration of 1%.

Embodiment 2

[0027] The resin composition of the first immersion solution provided in this embodiment comprises, by weight, 100 parts of polyurethane resin, 0.6 part of catalyst, 15 parts of sizing agent, 0.5 part of coupling agent, 1 part of ultraviolet absorber, 8 parts of flame retardant agent, 25 parts of defoamer and 20 parts of silicone fabric finishing agent, and 35 parts of curing agent. The second immersion solution is a chitosan solution with a concentration of 0.8%.

Embodiment 3

[0029] The resin composition of the first immersion solution provided in this embodiment includes, by weight, 100 parts of polyurethane resin, 0.4 part of catalyst, 23 parts of sizing agent, 0.4 part of coupling agent, 0.8 part of ultraviolet absorber, 6 parts of flame retardant agent, 20 parts of defoamer and 22 parts of silicone fabric finishing agent, and 30 parts of curing agent. The second immersion liquid is a chitosan solution with a concentration of 1.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com