Preparation method of ultra-low iron loss sendust core

A technology of sendust and ultra-low iron, which is applied in the field of preparation of ultra-low iron loss sendust cores, can solve the problems of limited reduction, achieve uniform structure, minimize eddy current loss, and high-frequency magnetic permeability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

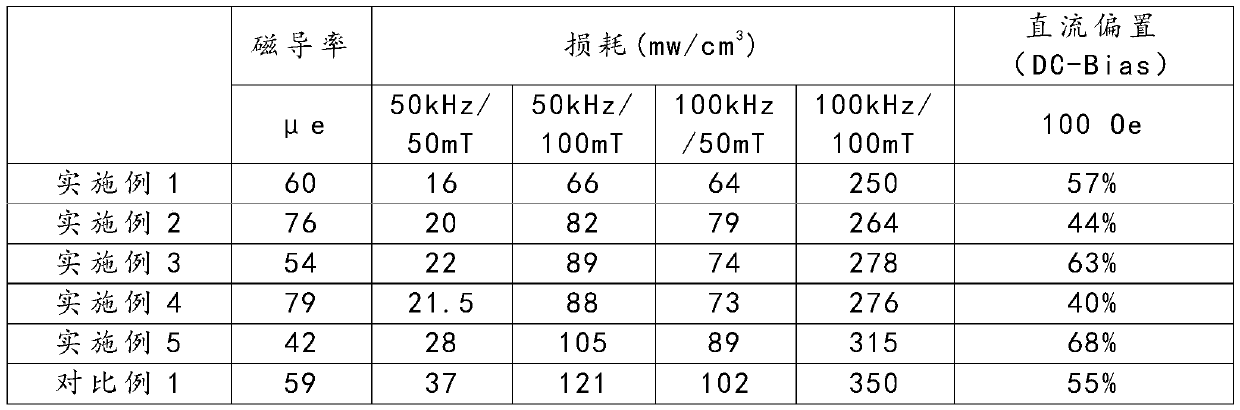

Examples

preparation example Construction

[0024] Embodiments of the present invention provide a method for preparing an ultra-low iron loss sendust core on the one hand, including:

[0025] Gas-atomized powder spraying to obtain gas-atomized Fe-Si-Al powder, pass the gas-atomized Fe-Si-Al powder through a 200-mesh sieve, take the powder under the sieve for insulation coating treatment, and then press and form to obtain a magnetic core, and anneal the magnetic core Finally, spray the insulating treatment agent on the surface of the magnetic core;

[0026] Wherein, the insulating coating treatment includes: pouring the water glass solution into the powder under the sieve and stirring until dry; adding mica powder and stirring evenly, then adding modified silicone resin and stirring evenly, and finally adding zinc stearate.

[0027] In this example, the gas atomized sendust powder obtained by gas atomization powder spraying is used. After sieving, the powder under the sieve has obtained a suitable magnetic permeability t...

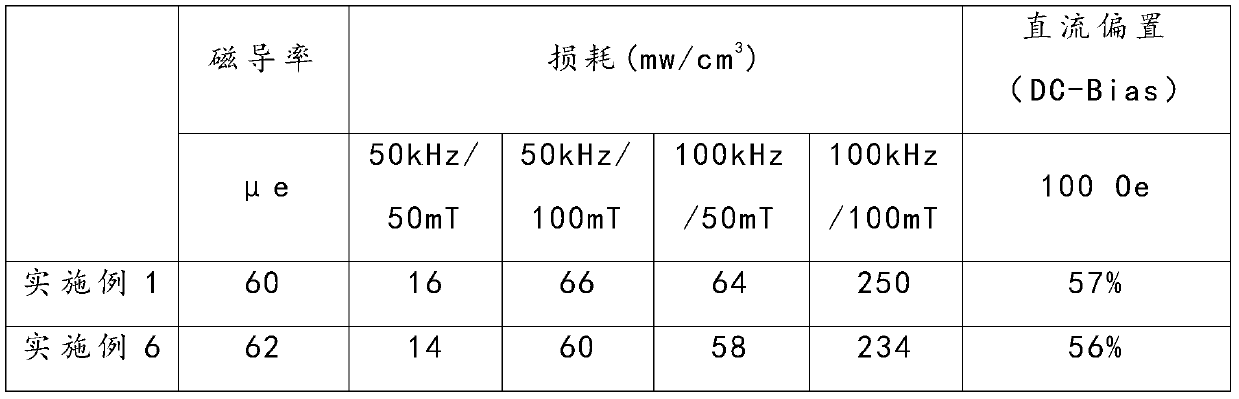

Embodiment 1

[0041]Gas atomized powder spraying to obtain gas atomized iron silicon aluminum powder (Al: 5.4%, Si: 9.6%, the rest is iron), pass the gas atomized iron silicon aluminum powder through a 200-mesh sieve, and take the powder under the sieve for insulation coating deal with;

[0042] Then the pressure is 20t / cm 2 , pressed into a magnetic core with an outer diameter of 27mm;

[0043] The magnetic core is annealed at 750°C for 30 minutes and protected by an atmosphere of liquid nitrogen.

[0044] After the annealing treatment, spray the insulating treatment agent epoxy resin on the surface of the magnetic core;

[0045] Wherein, the insulating coating treatment comprises: the water glass solution obtained by dissolving 2wt% water glass of the mass of the under-sieve powder in water is poured into the under-sieve powder, and stirred until dry; adding 0.5 wt% mica powder of the mass of the under-sieve powder Stir evenly, then add 1wt% modified silicone resin of the mass of the p...

Embodiment 2

[0047] Gas atomized powder spraying to obtain gas atomized iron silicon aluminum powder (Al: 5.4%, Si: 9.6%, the rest is iron), pass the gas atomized iron silicon aluminum powder through a 200-mesh sieve, and take the powder under the sieve for insulation coating deal with;

[0048] Then the pressure is 20t / cm 2 , pressed into a magnetic core with an outer diameter of 27mm;

[0049] The magnetic core is annealed at 750°C for 30 minutes and protected by an atmosphere of liquid nitrogen.

[0050] After the annealing treatment, spray the insulating treatment agent epoxy resin on the surface of the magnetic core;

[0051] Wherein, the insulating coating treatment comprises: the water glass solution obtained by dissolving 1wt% water glass of the mass of the powder under the sieve in water is poured into the powder under the sieve, stirred until dry; adding 0.2 wt% mica powder of the mass of the under-sieve powder Stir evenly, then add 0.5wt% modified silicone resin of the powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com