Natural heat dissipation apparatus of electronic device

A technology of natural heat dissipation and electronic devices, which is applied in the direction of electrical components, structural parts of electrical equipment, and modification through conduction and heat transfer. Low, to ensure the effect of cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

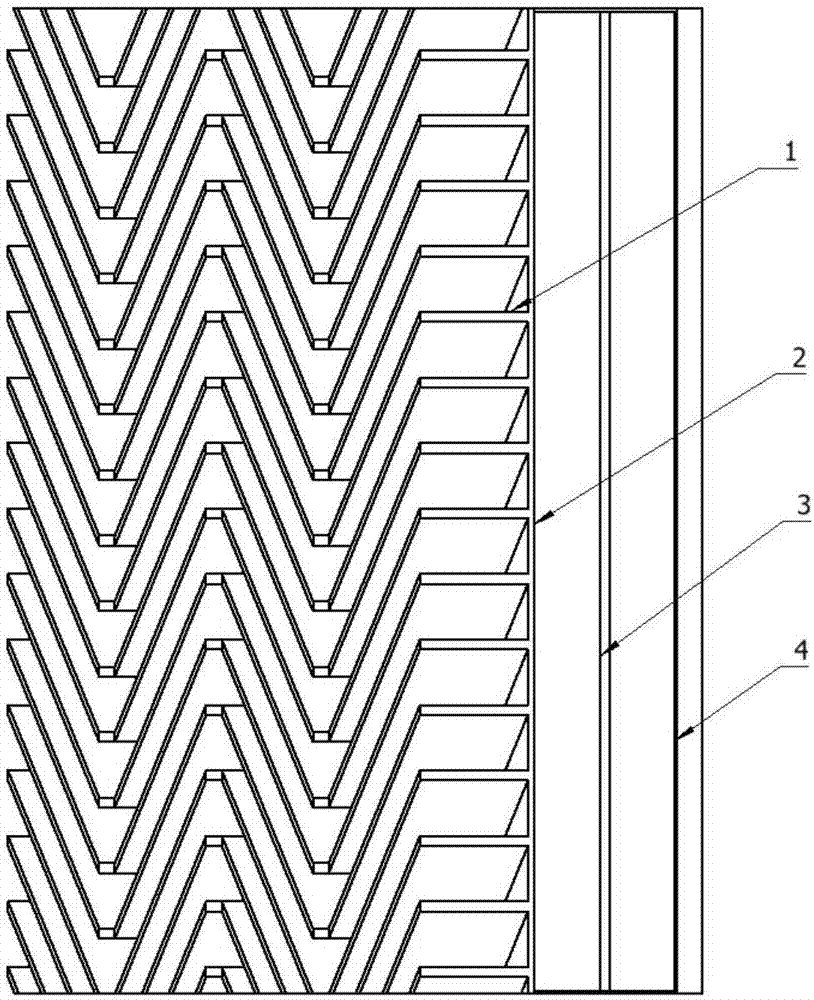

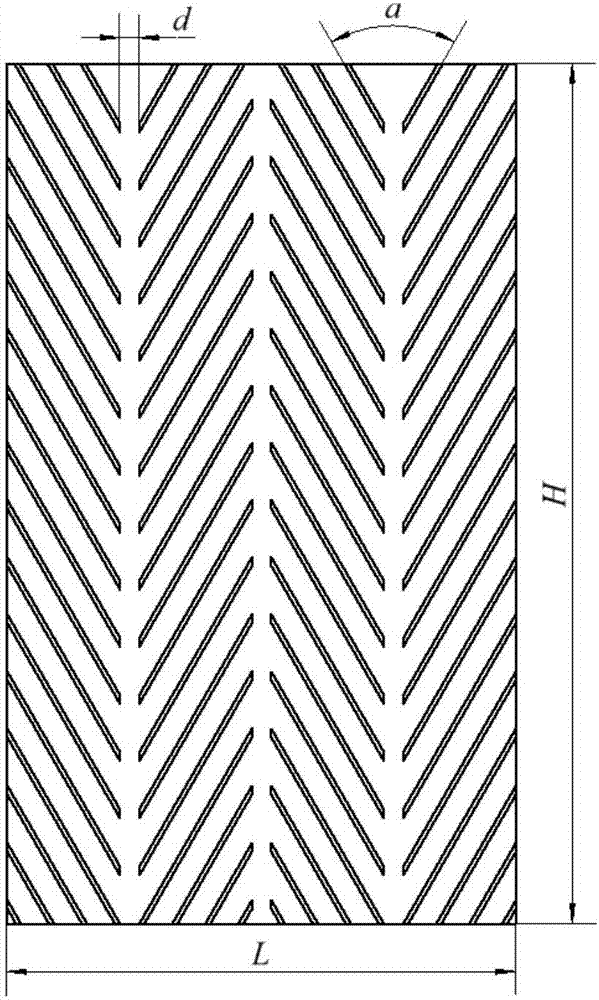

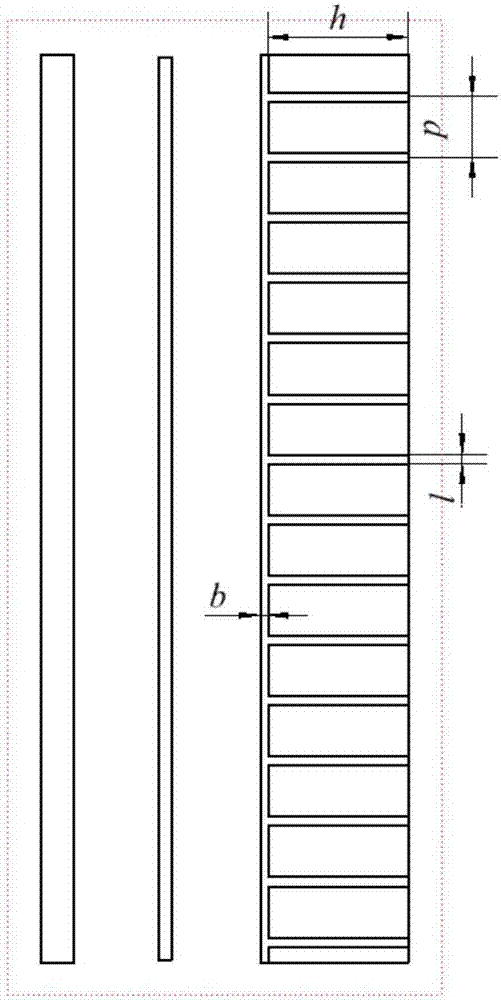

[0023] See attached figure 1 , the heat dissipation device of the present invention comprises a W-shaped heat dissipation fin 1 and a substrate 2 arranged at the bottom of the W-shaped heat dissipation fin 1, and a heat source aluminum plate 3 that is closely attached to the back of the substrate 2, and wraps the heat source aluminum plate 3 The heat-insulating rear shell 4; the corners of the W-shaped heat dissipation fins 1 are disconnected and evenly distributed on the substrate 2. Wherein, the opening angle a of the W-shaped heat dissipation fin 1 is 45° to 90°; the ratio of the dimension d of the disconnected part of the W-shaped heat dissipation fin 1 to the width dimension L of the substrate 2 is d / L=0.03~ 0.10; the ratio l / p of the thickness l of the W-shaped heat dissipation fin 1 to the width dimension L of the fin pitch p=0.05˜0.10.

[0024] The heat generated by the electronic device is transferred to the heat source of the aluminum plate through the heat pipe, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com