A non-preservative component composition with antibacterial effect and its preparation method and application

A technology for preservative ingredients and compositions, applied in the field of non-preservative ingredient compositions and their preparation, can solve the problems of dark color, allergy, poor broad-spectrum antibacterial properties and the like of non-preservative ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] A preparation method of a non-preservative component composition with antibacterial effect, comprising:

[0062] Adding steps at one time: add the p-hydroxyacetophenone in the formula amount into the vacuum stirring pot, heat to dissolve, and cool;

[0063] The second addition step: under the condition of stirring, sequentially add glycerin caprylate, caprylyl hydroxamic acid, propylene glycol, caprylyl glycol and ethylhexylglycerin in the prescribed amount, stir evenly, and vacuum degas to obtain a composition without antiseptic components.

[0064] As a further embodiment, in the first addition step, add the formula amount of p-hydroxyacetophenone into the vacuum stirring pot, heat to 65-70°C until the dissolution is complete, and then cool to 30-35°C; in the second addition step , maintain the stirring speed at 20-25r / min, add the prescribed amount of glycerin caprylate, caprylyl hydroxamic acid, propylene glycol, caprylyl glycol and ethylhexylglycerin in sequence, s...

Embodiment 1-3

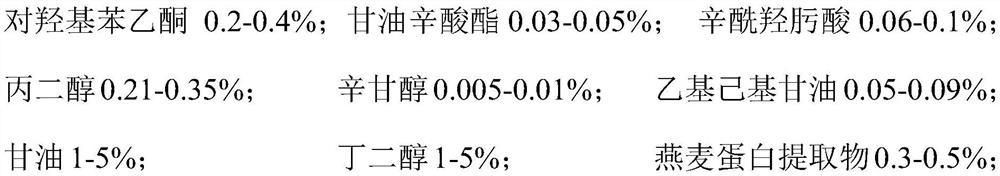

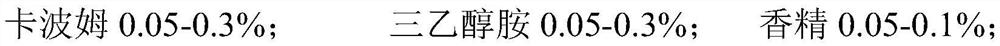

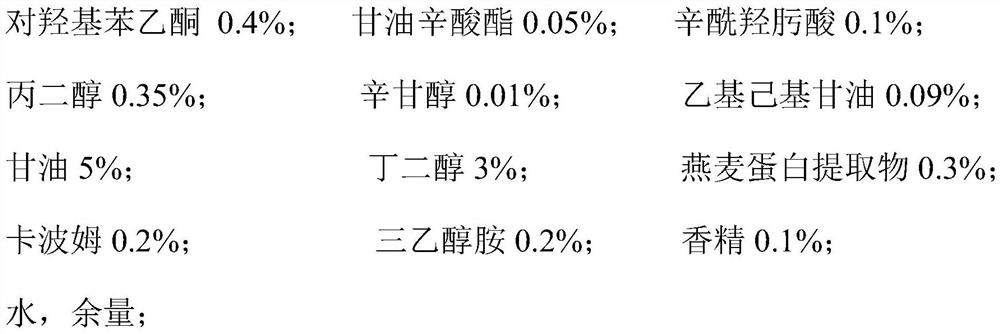

[0079] A serum consisting of water, glycerin, butylene glycol, oat protein extract, propylene glycol, para-hydroxyacetophenone, ethylhexylglycerin, caprylyl hydroxamic acid, glyceryl caprylate, caprylyl glycol, carbomer , triethanolamine and essence, the utensils of above-mentioned various compositions are as shown in table 1 below.

[0080] The essence formula table of table 1 embodiment 1-3 and comparative example 1

[0081] raw material name Example 1 Example 2 Example 3 Comparative example 1 water(%) T0 100 T0 100 T0 100 T0 100 glycerin(%) 5 5 5 5 Butanediol (%) 3 3 3 3 Oat protein extract (%) 0.3 0.3 0.3 0.3 Propylene glycol (%) 0.35 0.28 0.21 0 p-Hydroxyacetophenone (%) 0.4 0.3 0.2 0 Ethylhexylglycerin (%) 0.09 0.072 0.045 0 Caprylyl hydroxamic acid (%) 0.1 0.08 0.06 0 Glyceryl caprylate (%) 0.05 0.04 0.03 0 Caprylyl glycol (%) 0.01 0.008 0.005 0 Carbomer (%) 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com