Method for catalytic-oxidation purification and energy utilization of low-calorific-value industrial exhaust gas and device

A technology for industrial exhaust gas and catalytic purification, which is applied in the fields of environmental protection and low-grade resource utilization, and can solve the problem that the catalytic purification and energy utilization of industrial exhaust gas with low calorific value cannot be solved, the combustible components cannot be effectively oxidized, and the granular catalyst is not wear-resistant. It can solve the problems of catalyst carbon deposition, improve environmental performance and energy recovery rate, and achieve high safety and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

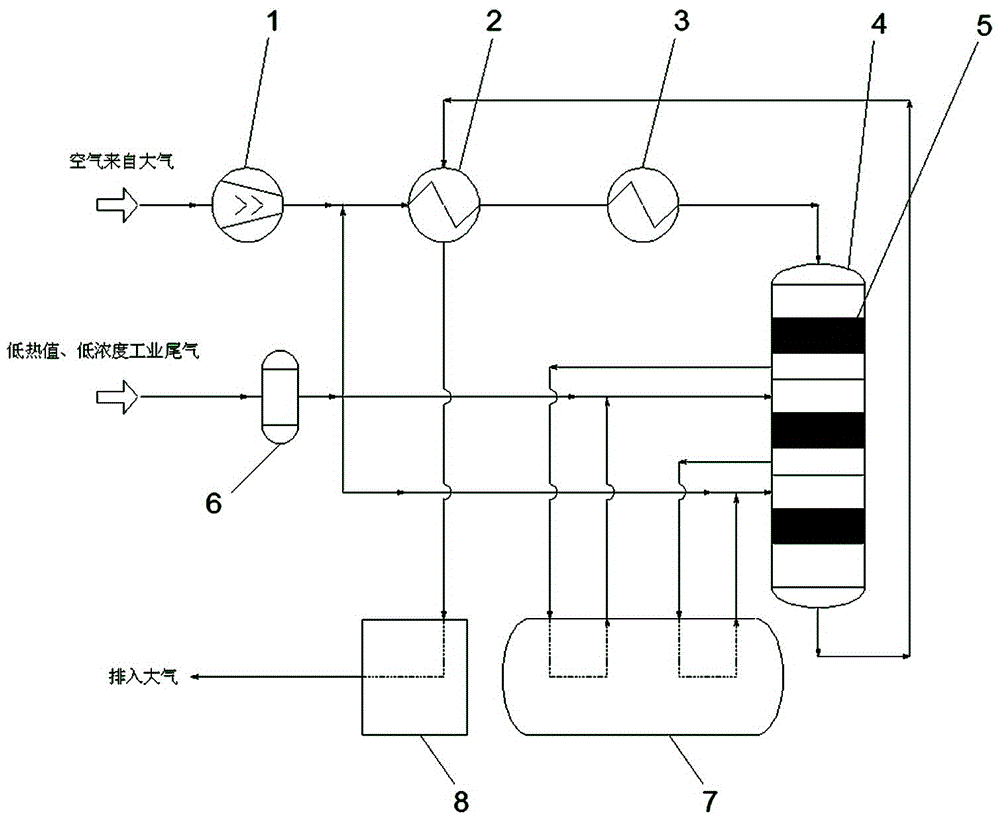

Embodiment 1

[0021] The flow rate is 500Nm 3 / h, the pressure is 41kpaG, the temperature is 35°C, the combustible component is 5% dust-free exhaust gas, and the 300Nm from the main pipe of the air compressor 3 / h, the pressure is 40 kPaG, after the air is fully mixed, it is heated to 350°C by starting the heater, and then sent to the catalytic reactor for complete catalytic oxidation and then heated to 489°C. The reactor inlet heater heats the inlet gas to 360°C, which itself is cooled and discharged to the atmosphere. The various components of the mixed gas leaving the catalytic reactor meet the national emission requirements. Due to the small gas volume and low pressure, there is no energy recovery value.

Embodiment 2

[0023] The flow rate is 24000Nm 3 / h, the pressure is 200kpaG, the temperature is 25°C, the total combustible components are 11% industrial tail gas, and the split flow is 8000Nm 3 / h and 15500Nm from the main pipe of the air compressor 3 / h, the pressure is 210kpaG, after the air is fully mixed, it is heated to 220°C by starting the heater, and sent to the first stage of the catalytic reactor for a complete catalytic oxidation reaction. While the mixed gas is purified, the reaction heat heats the mixed gas to 583°C , the high-temperature gas after the first-stage reaction passes through the waste heat boiler to recover heat and produce steam by-product, the temperature drops to 370°C, and then diverts the 8000Nm of the remaining tail gas 3 / h is fully mixed with the mixed gas after heat exchange at the outlet of the first stage, and sent to the second stage of the catalytic reactor for a complete catalytic oxidation reaction. While the mixed gas is purified, the reaction hea...

Embodiment 3

[0025] The flow rate is 40000Nm 3 / h, the pressure is 2000kpaG, the temperature is 23°C, the total combustible components are 15% industrial tail gas, and the split flow is 13000Nm 3 / h and 25500Nm from the main pipe of the air compressor 3 / h, the pressure is 2000kpaG, after the air is fully mixed, it is heated to 235°C by starting the heater, and then sent to the first stage of the catalytic reactor for a complete catalytic oxidation reaction. While the mixed gas is purified, the reaction heat heats the mixed gas to 590°C . After the first-stage reaction, the high-temperature gas passes through the waste heat boiler to recover the heat and produce steam by-product. The temperature drops to 310°C, and then the 13000Nm of the remaining tail gas is diverted. 3 / h is fully mixed with the mixed gas after heat exchange at the outlet of the first stage, and sent to the second stage of the catalytic reactor for complete catalytic oxidation reaction. While the mixed gas is purified,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com