Mobile intelligent computer numerical control gantry guide rail grinding machine

A rail grinding machine, computer technology, applied in the direction of grinding machine, grinding machine bed, grinding automatic control device, etc., can solve the problems of poor adaptability to the working environment, no heat dissipation function, short working life, etc., to improve working performance, The effect of convenient moving position and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

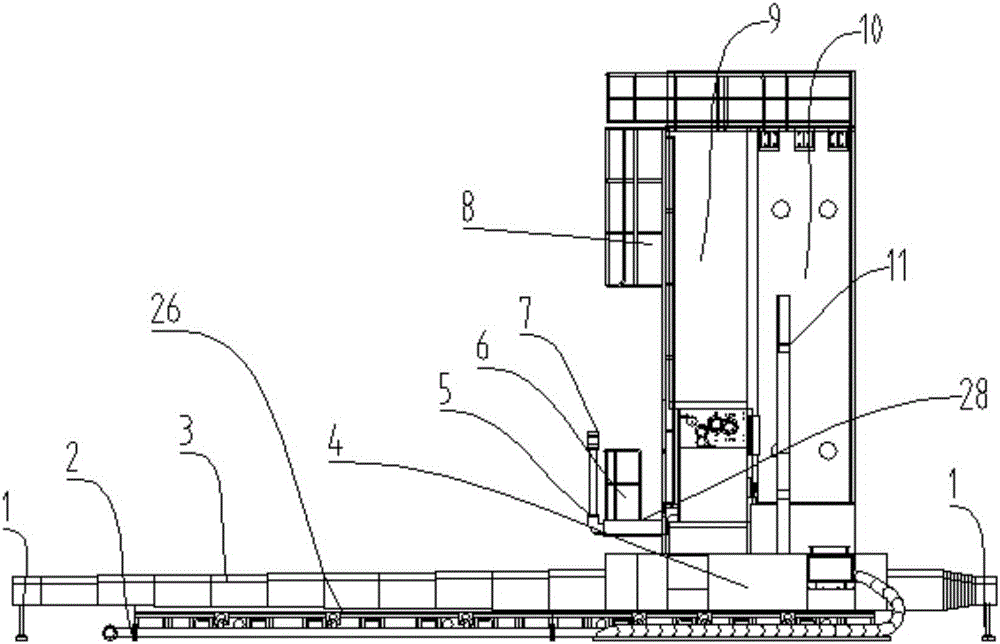

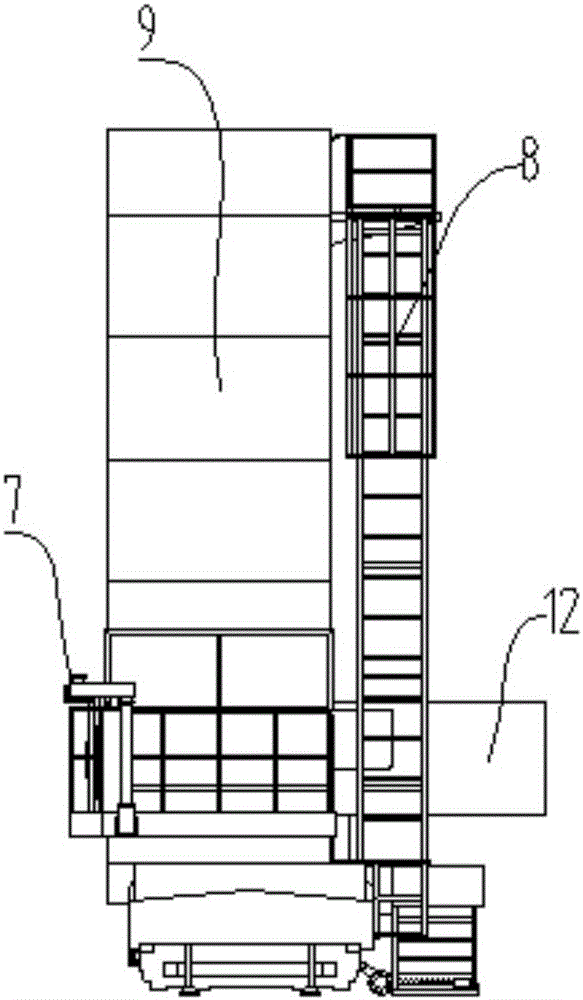

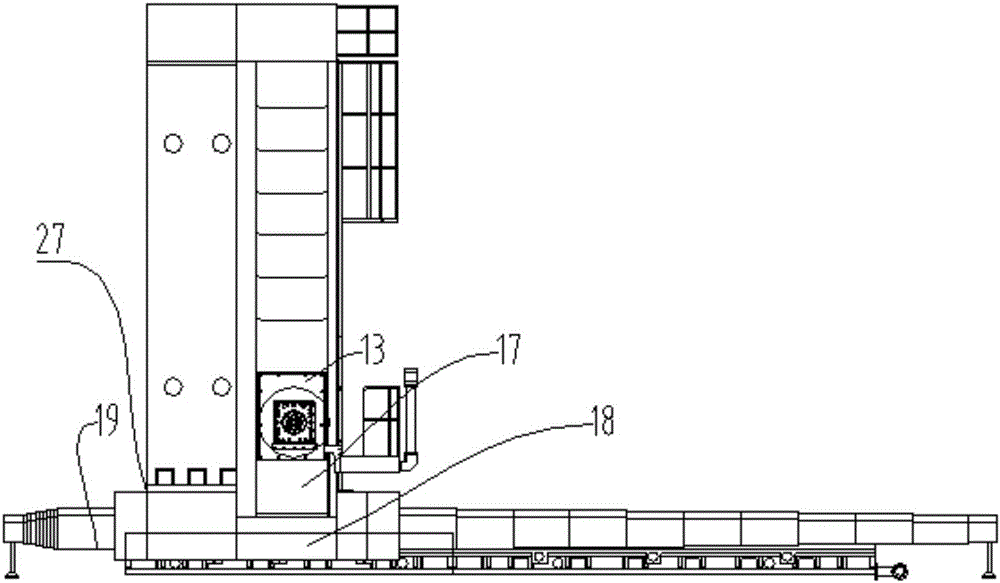

[0018] Such as Figure 1-Figure 5 As shown, a movable intelligent computer numerical control gantry guide rail grinding machine includes a mobile device 26, a grinding device 27, a control device 28 and a cooling device 29, a bed guide rail 3 is arranged above the mobile device 26, and the bed The bed guide rail 3 can provide a slide groove, and an oil pump 6 is arranged above the bed guide rail 3, and the oil pump 6 can press oil out for use by the mobile device 26. The above described bed guide rail 3 is provided with the A control device 28, the control device 28 can set the working data of the CNC grinding machine, monitor the work flow of the CNC grinding machine, a frame 8 is arranged above the oil pump 6, and the frame 8 is installed on the crossbeam 9, which can pass through the crossbeam 9 hoisting the components that need to be ground for processing, the beam 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com