Glass used for film solar energy battery substrate

A solar cell and glass technology, which is applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve problems such as the decline in performance indicators of solar cell devices, the inability to meet the high temperature process technology of batteries, and the low softening point of high temperature heating, so as to increase the softening point of glass , Ease of molding control, and the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] The invention provides a kind of glass suitable for thin-film solar cell substrates, including 58% SiO by mass percentage 2 , 9% Al 2 o 3 , 0.01% ZrO 2 , 4.49% K 2 O, 9% Na 2 O, 1% MgO, 5% CaO, 3% BaO, 10% SrO, 0.45% SnO 2 and 0.01% MoO 3 ; The above-mentioned components are melted and molded according to the glass preparation process to obtain the glass.

Embodiment 2

[0012] The invention provides a kind of glass suitable for thin-film solar cell substrates, including 55% SiO by mass percentage 2 , 12% Al 2 o 3 , 0.01% ZrO 2 , 4.49% K 2 O, 9% Na 2 O, 1% MgO, 5% CaO, 3% BaO, 10% SrO, 0.45% SnO 2 and 0.01% MoO 3 ; The above-mentioned components are melted and molded according to the glass preparation process to obtain the glass.

Embodiment 3

[0014] The invention provides a kind of glass suitable for thin-film solar cell substrates, including 56% SiO by mass percentage 2 , 11% Al 2 o 3 , 0.05% ZrO 2 , 4.49% K 2 O, 9% Na 2 O, 1% MgO, 5% CaO, 3% BaO, 10% SrO, 0.40% SnO 2 and 0.1% MoO; the above-mentioned components are melted and molded according to the glass preparation process to obtain the glass.

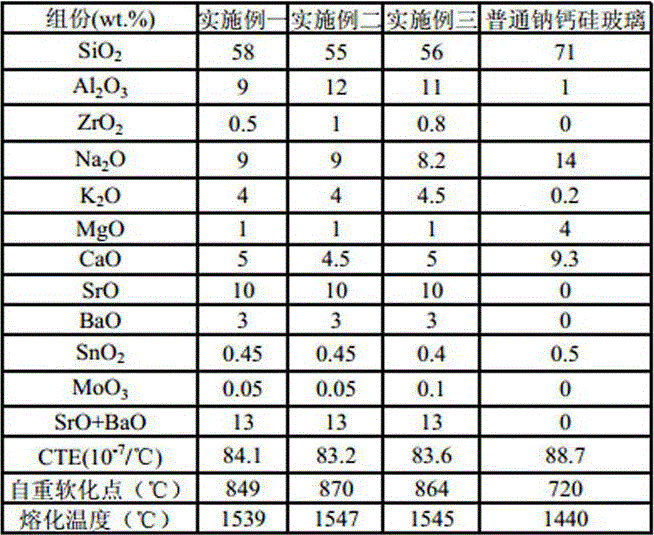

[0015] The glass that embodiment one to three makes is compared with each performance index by traditional component soda-lime glass, specifically see the following table:

[0016]

[0017] It can be seen from the above table that the coefficient of thermal expansion of the glass in Examples 1 to 3 is 80-85*10 -7 / °C, the weight softening point is above 840°C, which meets the high temperature process energy requirements of thin film solar cells. The thermal expansion coefficient of traditional soda-lime glass meets the requirements, but the softening point of its own weight is around 720°C, so the dimensional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com