Method for efficiently preparing high molecular material thickening system

A kind of polymer material and polymer technology, which is applied in the field of high-efficiency preparation of polymer material thickening system, can solve the problems affecting the guarantee of product quality, the deviation of thickener feeding amount, and inconvenient operation, so as to achieve the improvement of production efficiency and product quality. Good, easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

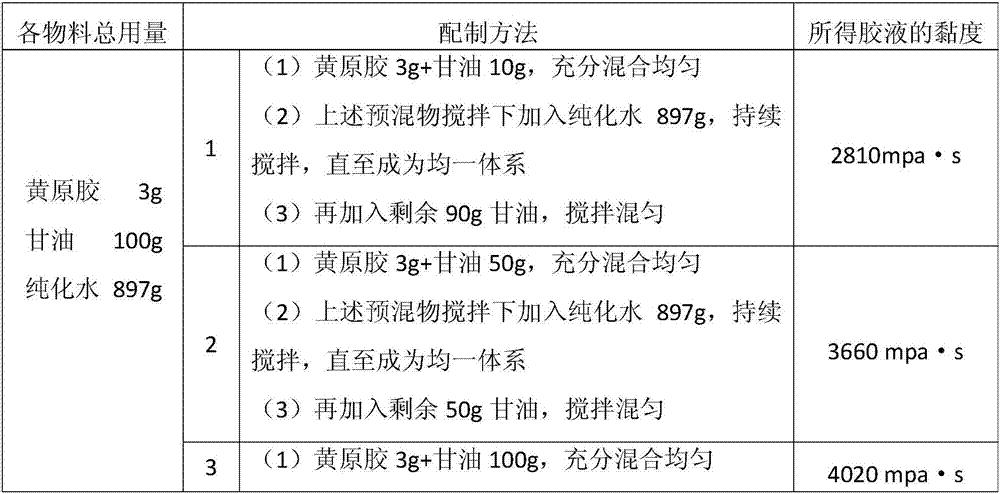

[0032] Embodiment 1 Traditional process and process contrast of the present invention-operation method, preparation time and result contrast

[0033] 3% xanthan gum-10% glycerin-water solution thickening system preparation

[0034] 1. Experimental method

[0035] The traditional craft preparation method is:

[0036] (1) Add 100g of glycerin into 870g of purified water, stir and mix;

[0037] (2) Sprinkle 30g of xanthan gum into it slowly while stirring, and continue to stir until the hydration is completely uniform and there are no visible particles and lumps, and no hard core.

[0038] In step (2), it is advisable to choose a preparation tank with a larger diameter to increase the spread area of the polymer substance on the liquid surface and increase its chance of contact with the solvent. The entire dissolving process takes 2-3 hours, and stirring should be continued during this period And pay attention to remove the xanthan gum adhering to the container wall and the s...

Embodiment 2

[0053] Embodiment 2 Comparison of traditional process and process of the present invention-screen retention result and viscosity retention situation comparison

[0054] The preparation method of the traditional process and the process method of the present invention is the same as in Example 1. The results are as follows

[0055] Table 1 Comparison of sieve retention results and viscosity retention

[0056] Compare items

Embodiment 3

[0057] Embodiment 3 traditional process and the process contrast of the present invention---consistency contrast between batches

[0058] The preparation method of the traditional process and the process method of the present invention is the same as in Example 1. The results are as follows

[0059] Table 2 Consistency comparison between batches

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com