Efficient cleaning device for etched foil and implementation method of device

A cleaning device and a technology for realizing the method are applied in the directions of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of unstable production, low chemical conversion efficiency, and flash fires in chemical forming tanks, and achieve cleaning The effect of good effect, high cleaning efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

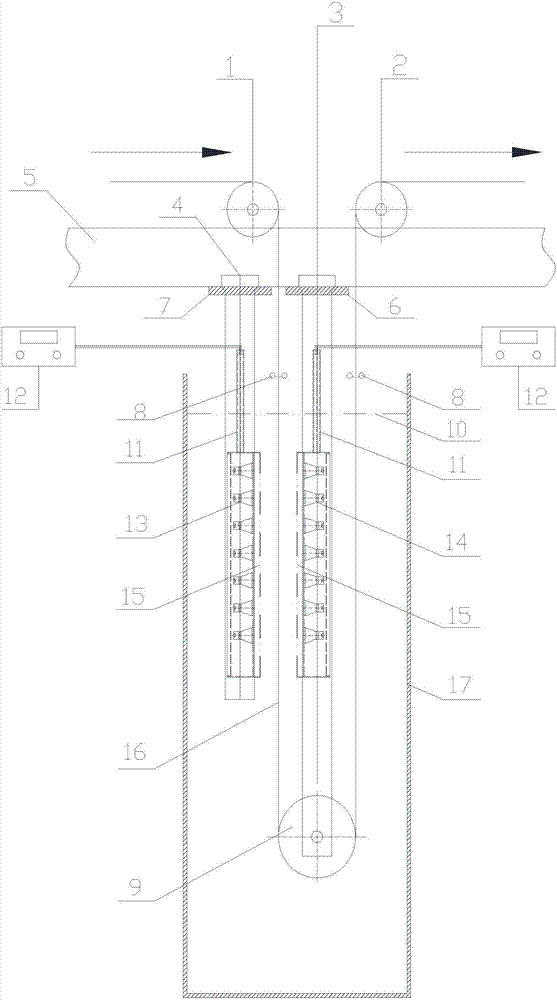

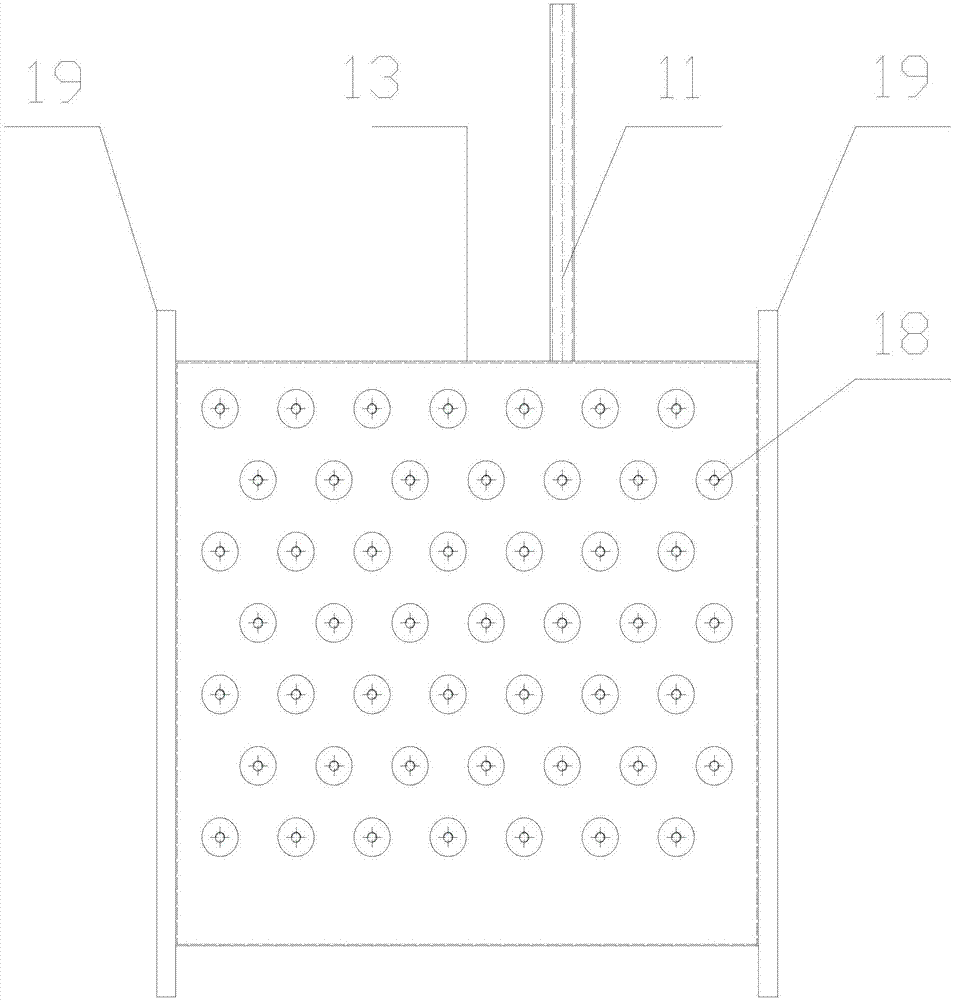

[0036] Such as Figure 1~2 As shown, a high-efficiency cleaning device for corroded foil includes a foil inlet roller and a foil outlet roller. The bottom of the girder is provided with a cleaning hanger support plate and a vibration box hanger support plate. The cleaning hanger and the vibration box hanger are installed on the corresponding support plate. The left vibration box is installed on the vibration box hanger, and the right vibration box is installed. On the cleaning hanger, the left vibrating box and the right vibrating box are set opposite to each other, the bottom roller is set under the cleaning hanger, the left vibrating box and the right vibrating box are respectively equipped with net covers, and the left vibrating box and the right vibrating box are respectively equipped with outlet pipes , connected to the ultrasonic generator through the power cord, spray pipes are installed under the foil inlet roller and the foil outlet roller respectively, and the spray ...

Embodiment 2

[0050] This embodiment differs from Embodiment 1 in that: the working frequency of the ultrasonic vibrator in this embodiment is 120 kHz; the distance between the left vibrating box and the right vibrating box is 200 mm.

[0051] In this embodiment, the ultrasonic vibration box in step (2) is immersed 150mm below the pure water surface.

[0052] The corroded foil is a negative electrode foil, the thickness of the corroded foil is 0.03mm, the ultrasonic cleaning time of the corroded foil is 6 seconds, and the power density of the ultrasonic cleaning is 5w / cm 2 within range.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com