An integrated device and method for hydraulic cooperative flotation treatment of sewage

A sewage and hydraulic technology, used in gas separation, liquid and solid fields, can solve the problems of inability to effectively remove suspended particles and oil components at the same time, damage to pipelines, equipment valves and pipe fittings, and affect biochemical advanced treatment, etc., to improve the harsh operation. The effect of high degree of automation, high degree of processing and fast processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

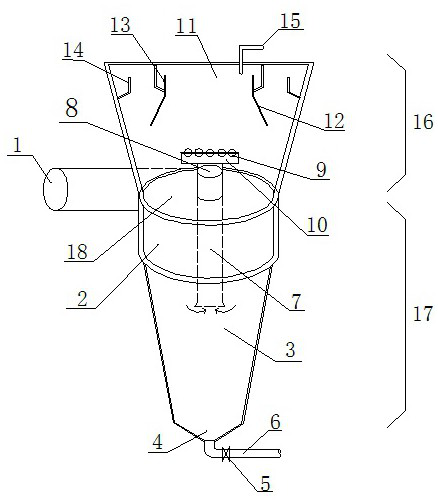

[0021] figure 1 It is a schematic diagram of an integrated device for treating sewage by hydraulic cooperative flotation according to the present invention.

[0022] like figure 1 As shown, the present invention provides an integrated device and method for hydraulic cooperative flotation treatment of sewage, wherein the integrated device for hydraulic cooperative flotation treatment of sewage is mainly composed of two parts: hydraulic separation zone 17 and flotation zone 16 .

[0023] The integrated device for hydraulic cooperative flotation treatment of sewage consists of two parts: a flotation area 16 and a hydraulic separation area 17 . Wherein, the releaser 9 is placed in the supporting tray 10; the supporting tray 10 is arranged on the upper side of the overflow port 8; the deflector 12 is arranged inside the ...

Embodiment 2

[0032] According to the integrated device and method for hydraulic cooperative flotation treatment of sewage provided in the above embodiments, according to the screening principle of solid particles in the fluid when they rotate in the desander, hydraulic separation and gas flotation technology are integrated, through two With the synergistic effect of these agents, the effects of sand removal, turbidity reduction, and solid-liquid separation are remarkable in the field of water treatment. In addition, the integrated device and method for hydraulic cooperative flotation treatment of sewage proposed by the present invention have low cost, stable treatment effect, reliable operation, and solid-liquid separation efficiency of 95%; when the design influent water quality COD≤400mg / L, BOD 5 ≤180 mg / L, SS≤220mg / L, continuous test, effluent water quality COD≤320mg / L, BOD 5≤144mg / L, SS≤10mg / L, the treatment effect is stable, the COD removal efficiency is stable at 60% to 80%, it can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com