Root-resistant water-based spraying and non-cured rubber asphalt waterproof coating

A kind of asphalt waterproof coating and non-curing rubber technology, which is applied in the direction of asphalt coating, coating, conjugated diene coating, etc., can solve the problems such as unsatisfactory adhesion effect of wet interface, health hazards of construction workers, long construction period, etc. Creep property and self-healing ability, improvement of construction efficiency and quality, strong bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

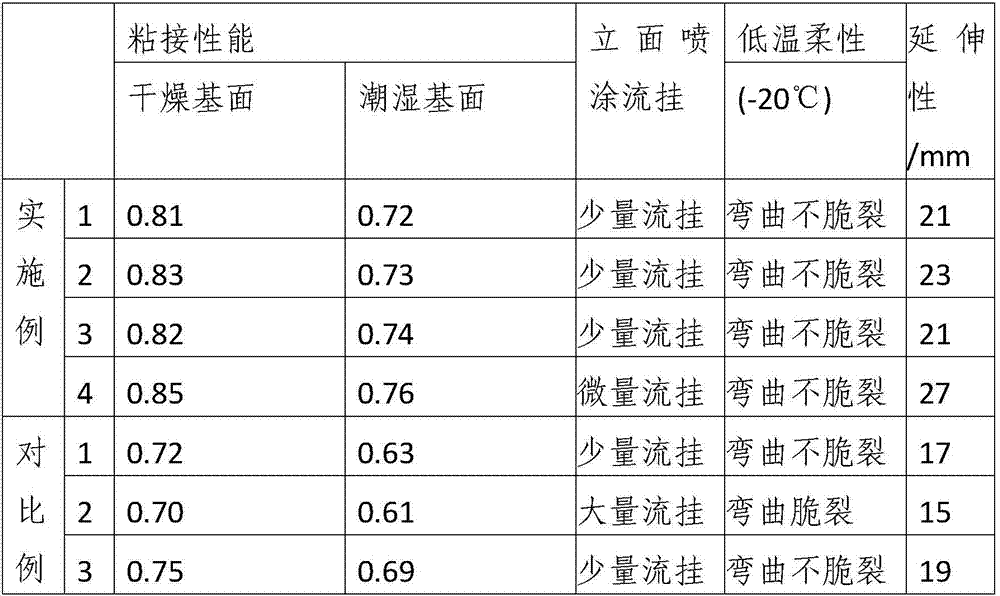

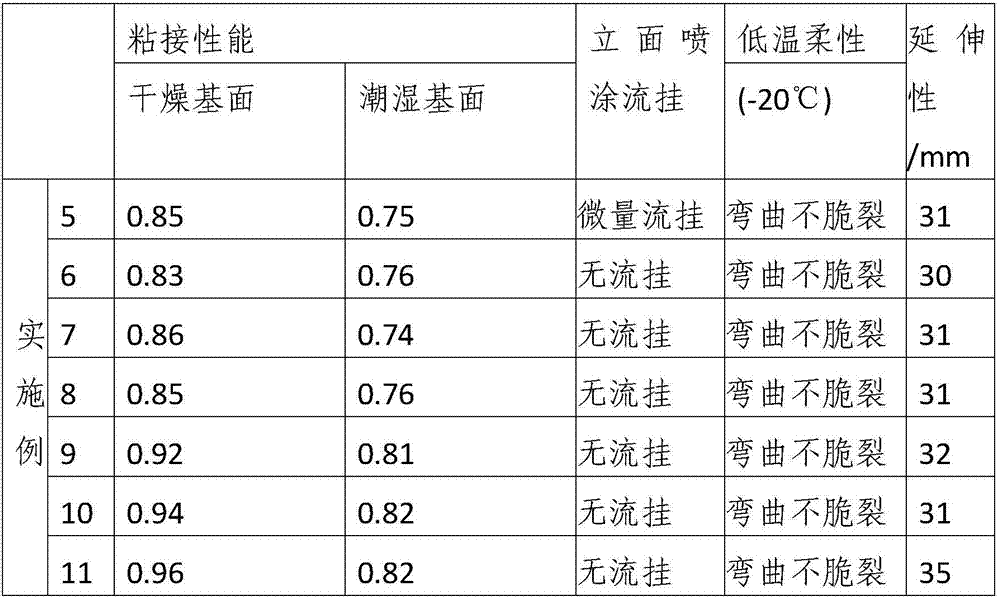

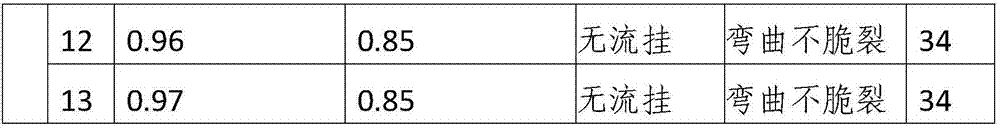

Examples

Embodiment 1

[0029] The anti-root puncture water-based spraying non-curing rubber asphalt waterproof coating composition of embodiment 1 comprises by weight parts:

[0030] 70 parts of anionic rubber elastomer modified emulsified asphalt, 8 parts of modified resin emulsion with a solid content of 70%, 2 parts of coagulation accelerator, 0.1 part of chemical root inhibitor, 0.005 part of defoamer, 0.3 part of dispersant, stabilizer 0.05 parts, 20 parts of filler;

[0031] Among them, the main composition of anionic rubber modified emulsified asphalt is 70 parts of base asphalt, 2 parts of SBS rubber particles, 4 parts of SBR rubber powder, 3 parts of NBR rubber powder, 40 parts of deionized water, 1 part of anionic emulsifier, nonionic surface active 2 parts of agent, 1 part of aromatic oil. Wherein the anionic emulsifier is selected from the group consisting of sulfate ester salt and nonionic surfactant alkylphenol polyoxyethylene ether; the modified resin emulsion is terpene resin emulsi...

Embodiment 2

[0034] The difference between embodiment 2 and embodiment 1 is that the anti-root puncture water-based spraying non-curing rubber asphalt waterproof coating composition includes by weight parts:

[0035] 80 parts of anionic rubber elastomer modified emulsified asphalt, 13 parts of modified resin emulsion with a solid content of 42%, 0.05 parts of coagulant, 3 parts of chemical root inhibitor, 0.9 part of defoamer, 0.003 part of dispersant, stabilizer 1 part, 5 parts of filler;

[0036] The composition and parts by weight of anionic rubber modified emulsified asphalt are: 60 parts of base asphalt, 2 parts of SBS rubber particles, 4 parts of SBR rubber powder, 3 parts of NBR rubber powder, 40 parts of deionized water, 1 part of anionic emulsifier, 2 parts of ionic surfactant, 1 part of naphthenic oil.

Embodiment 3

[0038] The difference between Example 3 and Example 1 is that there are 80 parts of anionic rubber elastomer modified emulsified asphalt, 13 parts of modified resin emulsion with a solid content of 42%, 0.05 parts of coagulation accelerator, 0.9 parts of defoamer, and 0.003 parts of dispersant 15 parts of chemical root inhibitor, 1 part of stabilizer, 5 parts of filler;

[0039] The composition and parts by weight of anionic rubber modified emulsified asphalt are: 40 parts of base asphalt, 5 parts of SBS rubber particles, 1 part of SBR rubber powder, 7 parts of NBR rubber powder, 10 parts of deionized water, 3 parts of anionic emulsifier, non- 0.5 parts of ionic surfactant, aromatic oil and naphthenic oil are added in a weight ratio of 1:1, and the sum of parts by weight is 3 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com