A kind of supple whitening laundry soap composition and preparation method thereof

A technology of laundry soap and composition, which is applied in the direction of detergent composition, soap detergent composition, surface active detergent composition, etc., which can solve the problems of loose soap body structure, cracking, and ineffective molding, etc., and achieves the preparation method simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

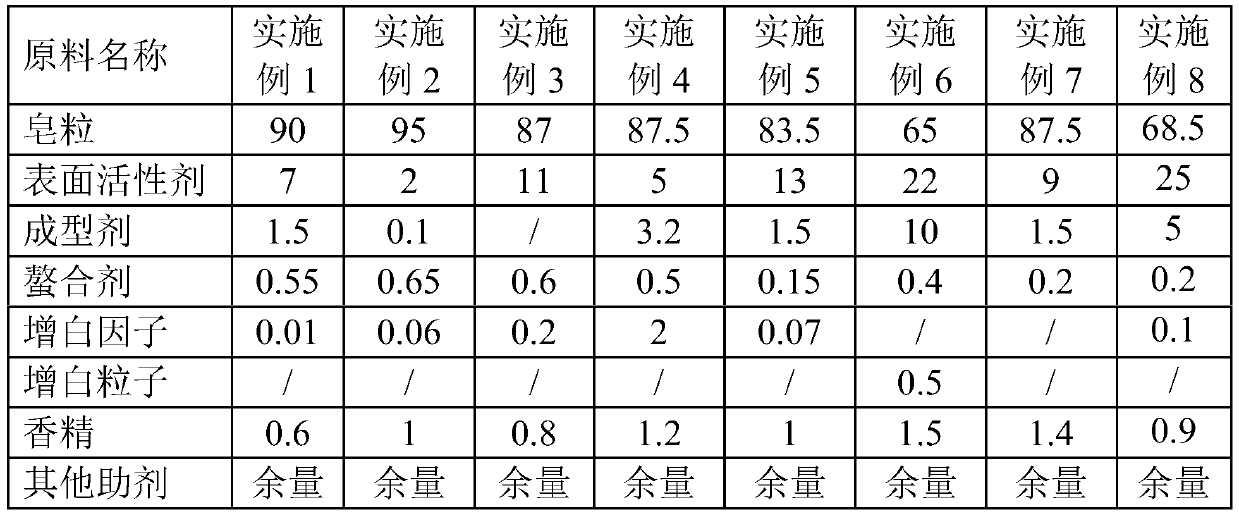

[0067] The material that each component is specifically used in the supple and whitening laundry soap composition of the present embodiment is as follows:

[0068] The soap grains are mixed oil soap grains, and the mixed oil soap grains refer to the soap grains that the fatty acids used in the soap grains are obtained by hydrolysis of animal oil and vegetable oil according to a certain proportion according to the existing technology, and obtained by neutralization and drying. The surfactant is compounded with fatty alcohol polyoxyethylene ether sulfate and sodium α-alkenyl sulfonate, and the mass ratio of fatty alcohol polyoxyethylene ether sulfate to sodium α-alkenyl sulfonate is 3:4. The forming agent is sodium carboxymethyl cellulose, the chelating agent is tetrasodium hydroxyethylidene diphosphonate, the whitening factor is Tinolux PSA15, the fragrance selection is jasmine fragrance essence, and the other additives are antioxidant dibutyl hydroxytoluene ( BHT).

[0069] T...

Embodiment 2

[0076] The material that each component is specifically used in the supple and whitening laundry soap composition of the present embodiment is as follows:

[0077] The soap grains are all vegetable oil soap grains. The so-called whole vegetable oil soap grains means that the fatty acids used in the soap grains are hydrolyzed from a single vegetable oil (palm oil, palm kernel oil or coconut oil) or different vegetable oils according to the existing technology in a certain proportion. And the soap particles obtained by neutralization and drying. Fatty alcohol polyoxyethylene ether is selected as the surfactant, PEG-4000 is selected as the forming agent, disodium hydroxyethylene diphosphonate is selected as the chelating agent, Violet 452 is selected as the whitening factor, lavender fragrance essence is selected as the fragrance selection, and other additives are selected Enzyme.

[0078] The preparation method of the softening and whitening laundry soap composition of this imp...

Embodiment 3

[0080] The material that each component is specifically used in the supple and whitening laundry soap composition of the present embodiment is as follows:

[0081] The soap particles are made of mixed oil soap particles. The mixed oil soap particles refer to the fatty acids used in the soap particles are obtained by hydrolyzing animal oil and vegetable oil according to a certain proportion according to the existing technology, and obtained by neutralization and drying. The surfactant is selected The combination of fatty alcohol polyoxyethylene ether and fatty acid methyl ester sulfonate, the mass ratio of A fatty alcohol polyoxyethylene ether and fatty acid methyl ester sulfonate is 3:8. This embodiment does not select to add molding agent, and chelating agent selects the disodium hydroxyethylidene diphosphonate for use, and the whitening factor selects Duasyn Red N6B for use, and the citrus fragrance type essence used for the fragrance selection, and other auxiliary agents sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com