High deformation control method for longspan tunnel in water-bearing stratum of chlorite quartz schist

A control method and technology of quartz flakes are applied in tunnels, tunnel linings, underground chambers, etc., to achieve the effects of improving the bearing capacity and stability of surrounding rock, ensuring construction efficiency and construction safety, and fast settlement rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

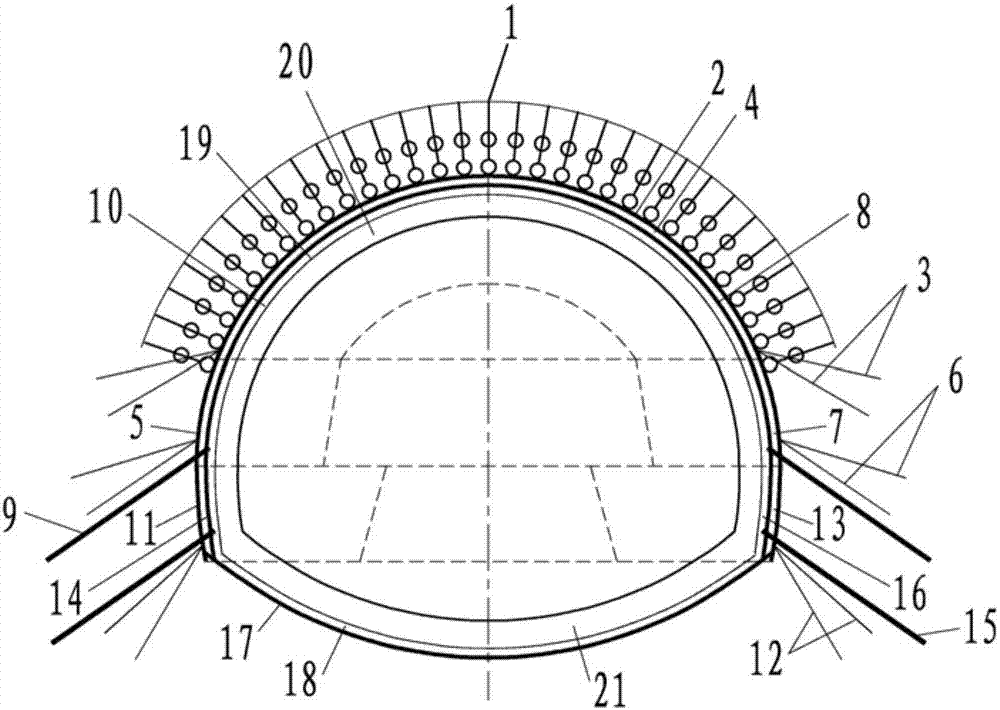

[0037] The present invention provides a large deformation control method for large-span tunnels in chlorite-quartz schist water-bearing formations, based on the three-step annular excavation method for reserving core soil, such as figure 1 As shown, tunnel expansion and support are carried out under advanced support, in which double-layer HK200b steel frames are used at the arch and side walls of the tunnel, and support is carried out in stages, in which the first layer of steel frame is used The corresponding reserved deformation is 50~90cm, and the corresponding reserved deformation is 25~45cm when the second layer of steel frame is constructed. The inverted arch adopts a single-layer HK200b steel frame. Double-layer Φ8 steel mesh, grid spacing 20×20cm, specifically includes the following steps:

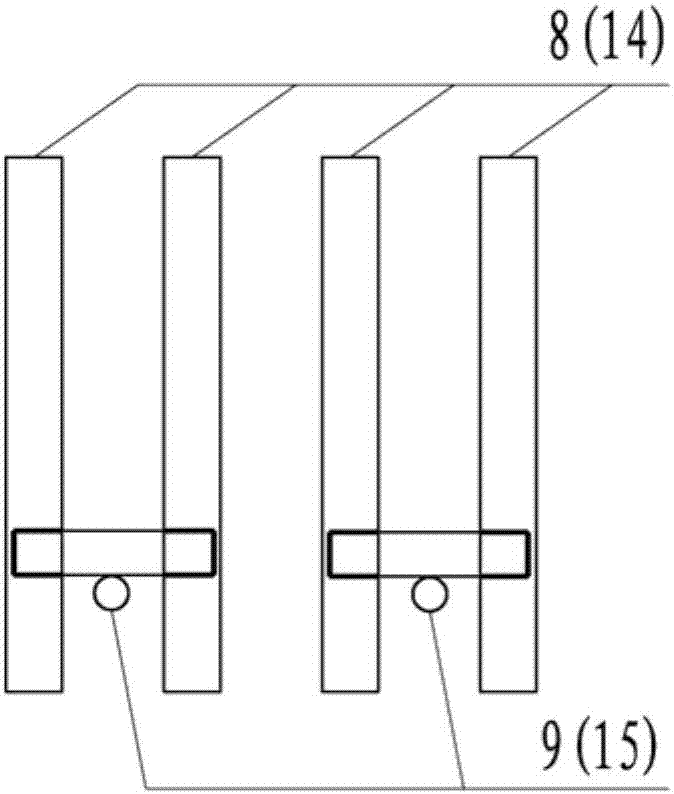

[0038] (1) Advance support: use double rows of 3.5m long Φ50 advance grouting small conduits 1 with a circumferential spacing of 40cm, and make 1 ring for every 2 steel frames.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com