Antarctic Krill Oil

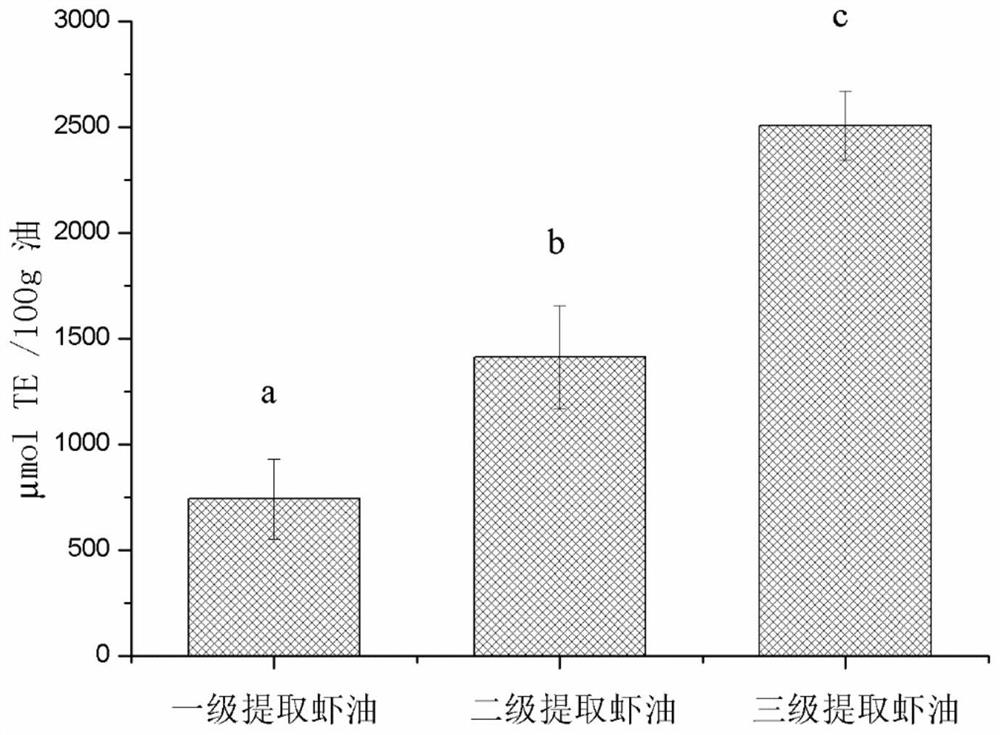

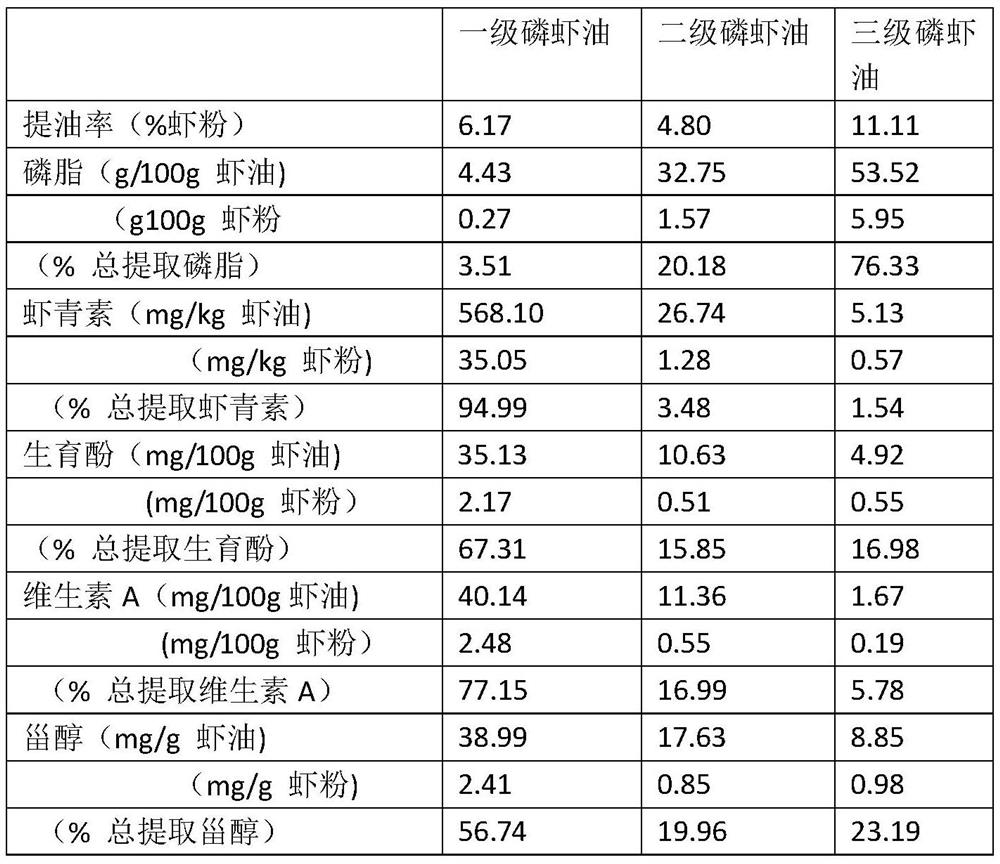

An Antarctic krill oil and Antarctic krill meal technology, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of limited krill oil, differences in the content of phospholipid trace components, and difficulty in maintaining consistency, and achieve excellent results. Antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Take 100g of Antarctic krill powder, first-stage extraction: mix krill powder with acetone (pre-cooled at 4°C for 6h) at a ratio of 1:2 (w / v), stir at 4°C for 15min, and the stirring speed is 300r / min, after the stirring is finished, it is filtered with a Buchner funnel, and the filtrate is precipitated and dried to obtain the first-grade extracted Antarctic krill oil. After weighing, the oil yield is calculated and the chemical composition is determined. The antarctic krill powder filtered out after the primary extraction is dried and desolvated under the conditions of 60°C and -0.1Mpa, and weighed for later use;

[0034] (2) Second-stage extraction: Mix the shrimp powder obtained after (1) extraction with n-hexane at a ratio of 1:2 (w / v), stir at 30°C for 15 minutes, and the stirring speed is 300r / min. The Buchner funnel was used to filter, and the filtrate was precipitated and dried to obtain secondary extracted Antarctic krill oil. After weighing, the yield of ...

Embodiment 2

[0039] (1) Take 200g of Antarctic krill powder, first-stage extraction: mix krill powder with acetone (pre-cooled at 10°C for 6h) at a ratio of 1:3 (w / v), stir at 10°C for 10min, and the stirring speed is 200r / min, after the stirring is finished, it is filtered with a Buchner funnel, and the filtrate is precipitated and dried to obtain the first-grade extracted Antarctic krill oil. After weighing, the oil yield is calculated and the chemical composition is determined. The antarctic krill powder filtered out after the primary extraction is dried and desolvated under the conditions of 60°C and -0.1Mpa, and weighed for later use;

[0040] (2) Second-stage extraction: Mix the shrimp powder obtained after (1) extraction with isohexane at a ratio of 1:3 (w / v), stir at 30°C for 15 minutes, and the stirring speed is 300r / min. The Buchner funnel was used to filter, and the filtrate was precipitated and dried to obtain secondary extracted Antarctic krill oil. After weighing, the yield ...

Embodiment 3

[0045] (1) Take 250g of Antarctic krill powder, first-stage extraction: mix krill powder with acetone (pre-cooled at 0°C for 6h) at a ratio of 1:3 (w / v), stir at 0°C for 20min, and the stirring speed is 100r / min, after the stirring is finished, it is filtered with a Buchner funnel, and the filtrate is precipitated and dried to obtain the first-grade extracted Antarctic krill oil. After weighing, the oil yield is calculated and the chemical composition is determined. The antarctic krill powder filtered out after the primary extraction is dried and desolvated under the conditions of 60°C and -0.1Mpa, and weighed for later use;

[0046] (2) Second-stage extraction: Mix the shrimp powder obtained after the extraction in (1) with n-hexane at a ratio of 1:3 (w / v), stir at 25°C for 20 minutes, and the stirring speed is 200r / min. The Buchner funnel was used to filter, and the filtrate was precipitated and dried to obtain secondary extracted Antarctic krill oil. After weighing, the yi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com