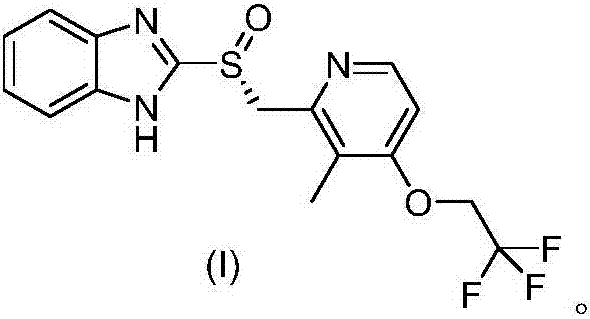

Preparation method of anhydrous dextro lansoprazole

A technology of dexlansoprazole and dexlansoprazole hydrate, applied in the field of preparation of anhydrous dexlansoprazole, can solve the problem of poor sample stability, poor water removal effect, dexlansoprazole The water content of azoles does not meet the requirements and other problems, and achieves the effect of simple operation, good stability and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

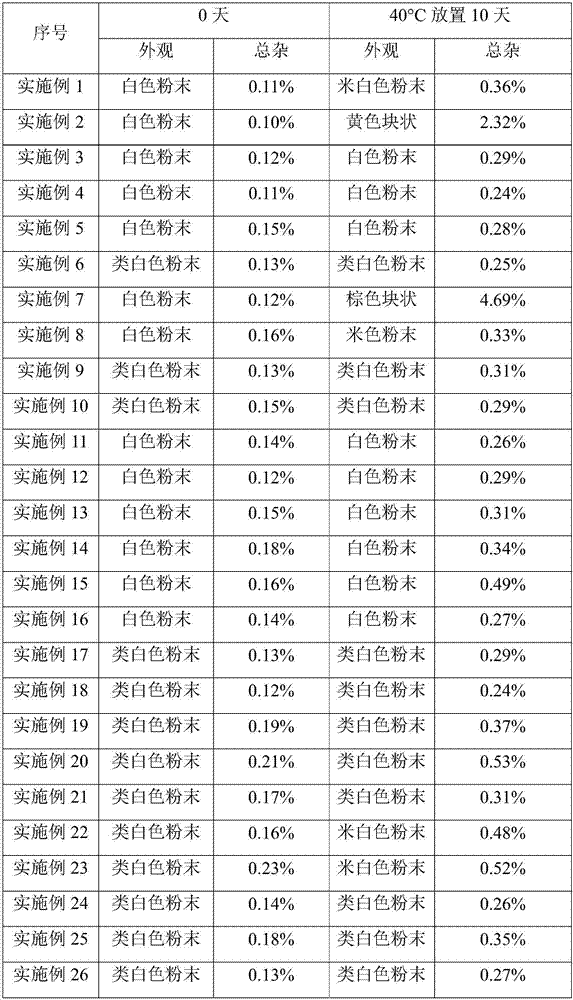

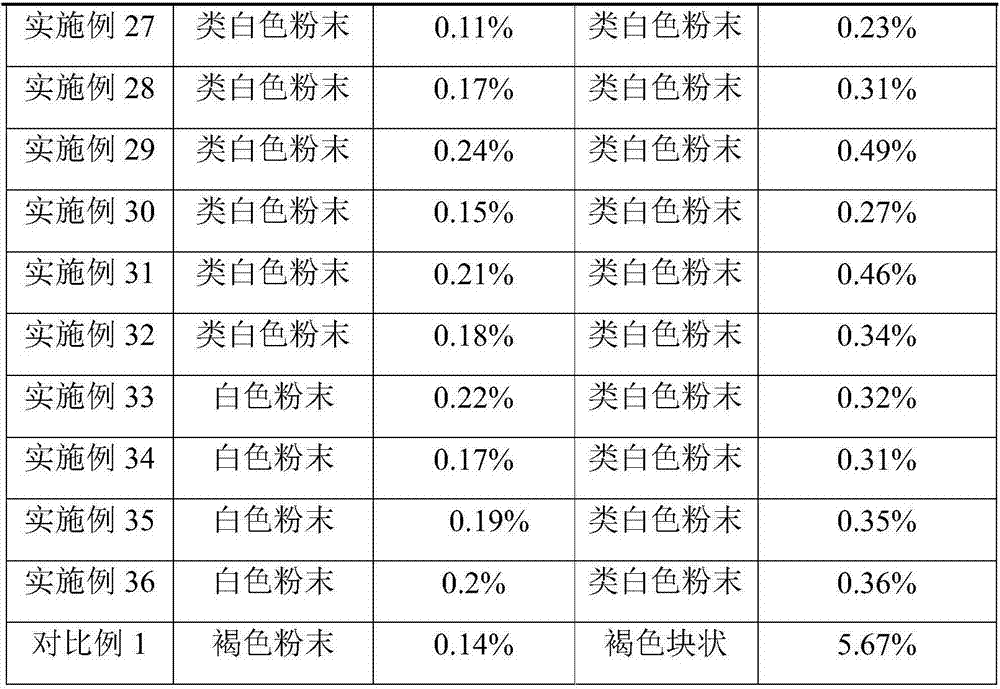

Examples

Embodiment 1

[0029] Weigh D-lansoprazole hydrate (water content 7.5%, 8g) and suspend it in isopropyl ether (40mL), stir at room temperature evenly, concentrate under reduced pressure at 35°C to dryness, add isopropyl ether (40mL), stir evenly Concentrate under reduced pressure to dryness, add isopropyl ether (40mL) again, stir evenly, concentrate under reduced pressure to dryness, add isopropyl ether (40mL), stir and beat at room temperature for 30 minutes, suction filter, wash with isopropyl ether, collect and filter The cake was vacuum-dried at 25° C. for 8 hours to obtain 7.17 g of anhydrous D-lansoprazole as a white solid, with a yield of 89.6% and a water content of 0.49%.

Embodiment 2

[0031] Weigh D-lansoprazole hydrate (water content 7%, 8g) and suspend it in ether (40mL), stir evenly at room temperature, concentrate under reduced pressure at 25°C to dryness, add ether (40mL), stir evenly and concentrate under reduced pressure To dryness, diethyl ether (40 mL) was added again, stirred evenly, concentrated to dryness under reduced pressure, diethyl ether (40 mL) was added, stirred and beaten at room temperature for 30 minutes, suction filtered, washed with diethyl ether, the filter cake was collected, and vacuum-dried at 25°C for 8 hours. Obtained 7.27 g of anhydrous dexlansoprazole in the form of a white solid, with a yield of 90.9% and a water content of 1.70%.

Embodiment 3

[0033] Weigh D-lansoprazole hydrate (water content 15%, 10g) and suspend it in methyl tert-butyl ether (50mL), stir evenly at room temperature, concentrate to dryness under reduced pressure at 28°C, add methyl tert-butyl ether (50mL), stirred evenly, concentrated to dryness under reduced pressure, added methyl tert-butyl ether (50mL) again, stirred evenly, concentrated to dryness under reduced pressure, added methyl tert-butyl ether (50mL), stirred and beat at room temperature for 30 minutes , filtered with suction, washed with methyl tert-butyl ether, collected the filter cake, and vacuum-dried for 8 hours at 25°C to obtain 8.36g of anhydrous D-lansoprazole as a white solid, with a yield of 83.6%, and a water content of 0.29%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com