Quick-drying hydroxyl acrylic resin for automobile refinishing coatings, and preparation method of quick-drying hydroxyl acrylic resin

A technology of fast-drying hydroxyacrylic acid and car refinish paint, applied in the field of hydroxy acrylic resin, can solve the problem that the drying speed of car refinish paint is getting lower and lower, shorten the hard drying time, improve wear resistance, and speed up the reaction speed of paint film Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

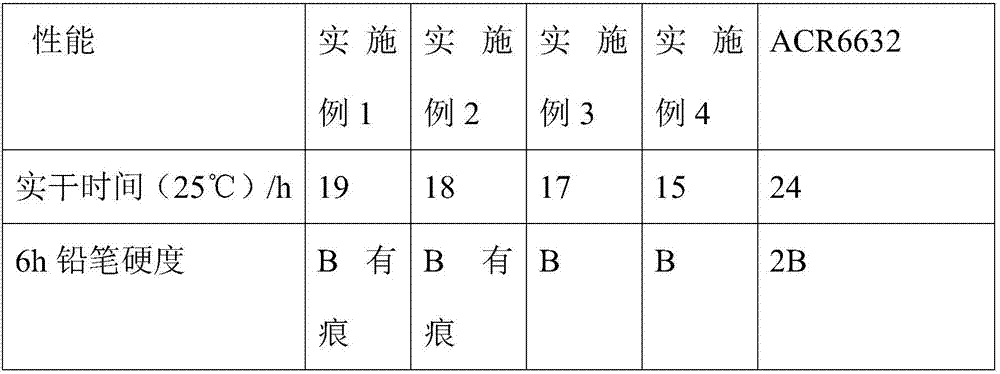

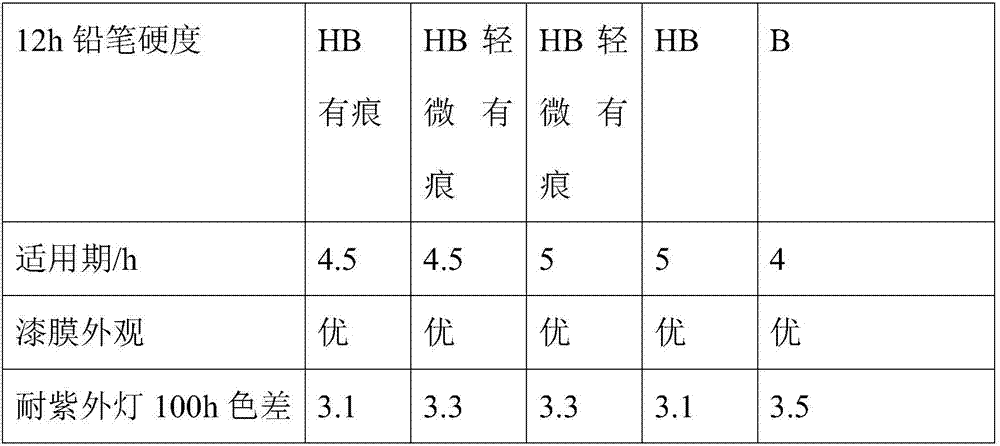

Examples

Embodiment 1

[0036] 1) Throw 10kg of butyl acetate and 25kg of xylene into the reaction kettle, and raise the temperature to 130°C;

[0037] 2) Take 1kg of acrylic acid, 30kg of methyl methacrylate, 10kg of butyl acrylate, 15kg of hydroxyethyl acrylate, 10kg of 4-hydroxybutyl acrylate, and 10kg of benzoyl peroxide to form material B, stir evenly, and drop it evenly over 3 hours In the reactor, the temperature is controlled at 130°C;

[0038] 3) After the dropwise addition, keep at 130°C for 2 hours;

[0039] 4) Add C material benzoyl peroxide 1kg, and maintain at 130°C for 3 hours;

[0040] 5) Cool down to 80°C and discharge.

Embodiment 2

[0042] 1) Throw 15kg of butyl acetate and 20kg of xylene into the reaction kettle, and raise the temperature to 130°C;

[0043] 2) Take 1kg of acrylic acid, 35kg of methyl methacrylate, 10kg of butyl acrylate, 10kg of hydroxyethyl acrylate, 15kg of 4-hydroxybutyl acrylate, and 12kg of benzoyl peroxide to form material B, stir evenly, and drop it evenly over 3 hours In the reactor, the temperature is controlled at 130°C;

[0044] 3) After the dropwise addition, maintain at 130°C for 2 hours;

[0045] 4) Add C material benzoyl peroxide 1kg, and maintain at 130°C for 3 hours;

[0046] 5) Cool down to 80°C and discharge.

Embodiment 3

[0048] 1) Throw 20kg of butyl acetate and 15kg of xylene into the reaction kettle, and raise the temperature to 135°C;

[0049] 2) Take 1kg of acrylic acid, 30kg of methyl methacrylate, 10kg of butyl methacrylate, 15kg of hydroxyethyl methacrylate, 20kg of 4-hydroxybutyl acrylate, and 10kg of tert-butyl peroxybenzoate to form material B, and stir evenly , drop evenly into the reactor for 3 hours, and control the temperature at 135°C;

[0050] 3) After the dropwise addition, maintain at 135°C for 2 hours;

[0051] 4) Add C material tert-butyl peroxybenzoate 1kg, and maintain at 135°C for 3 hours;

[0052] 5) Cool down to 80°C and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com