Method for refining lead and zinc from coarse zinc oxide recycled from steelmaking dust

A technology for recovery of coarse zinc oxide and dust, which is applied in the field of refining lead and zinc, can solve the problems of increased steelmaking dust production, environmental pollution, etc., and achieves the effect of convenient operation and simple process

Inactive Publication Date: 2017-12-12

CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

View PDF10 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the generation of electric furnace steelmaking dust of the designated waste has also increased, and at the same time, it has also brought about social problems of environmental pollution.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0053] The crude zinc oxide products actually recovered from the electric furnace steelmaking dust are used as starting materials, and the above crude zinc oxide is manufactured into spherical particles of 1-5 mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

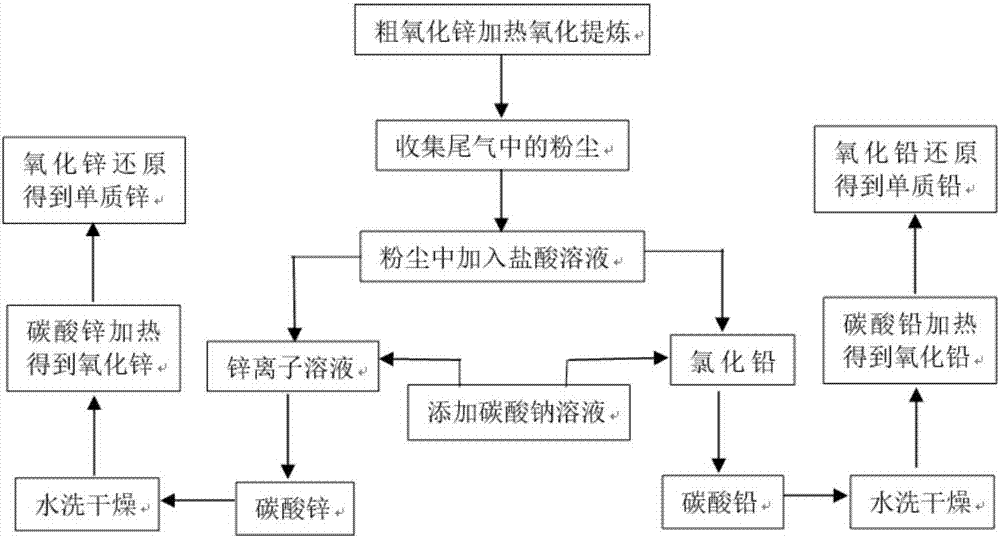

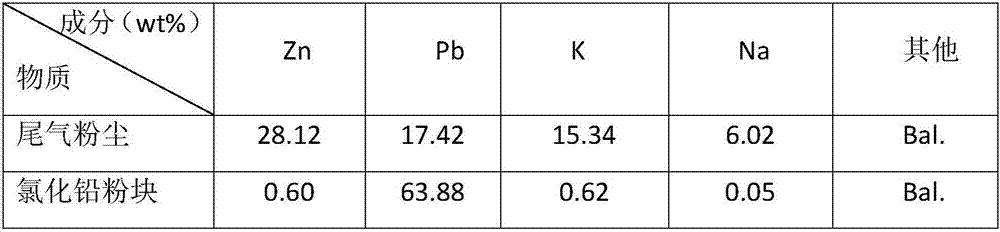

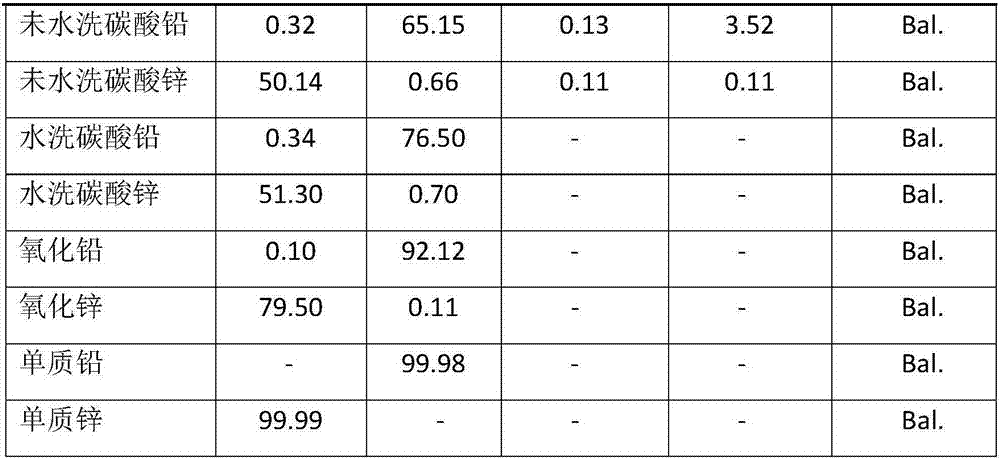

The invention discloses a method for refining lead and zinc from coarse zinc oxide recycled from steelmaking dust and belongs to the technical field of metal recycle. The method comprises the following steps that (1) the coarse zinc oxide is made into spherical particles, and the spherical particles are added into an oxidizing smelting furnace to be heated, oxidized and refined; (2) zinc and lead elements volatilize out of a furnace body in a gaseous form and become dust after meeting oxygen, and the dust containing the zinc and lead is collected through a container; (3) the dust is put into a hydrochloric acid solution to be stirred and dissolved, the zinc component exists in a zinc ion solution form, and the lead component exists in a lead chloride solid form; (4) a sodium carbonate solution is added into the zinc ion solution, zinc carbonate is generated, a sodium carbonate solution is added into the lead chloride, and lead carbonate is generated; and (5) washing and drying are conducted. According to the method, the process is simple, operation is convenient, the purity of PbCO3 and ZnCO3 which are finally obtained can reach 98% or above, the purity of PbO and ZnO reaches 99% or above, and the elementary substances Zn and Pb reach 99.9% or above.

Description

technical field [0001] The invention belongs to the technical field of metal recovery, and relates to a method for refining lead and zinc from crude zinc oxide recovered from steelmaking dust. Background technique [0002] In the electric furnace steelmaking dust, the scattered dust or gas state passes through the cooling process, and the collected particulate phase dust contains a large amount of valuable metals. Usually, in the electric furnace steelmaking method that uses scrap iron as the main raw material to produce steel, the amount of scrap iron put into the electric furnace steelmaking dust generated by the melting process is about 1 to 2%, and such electric furnace steelmaking dust contains a lot Valuable metals, such as lead, zinc, iron, etc. According to the different quality of electric furnace steelmaking company and steelmaking scrap iron, the lead content in the dust is 1-7%, the zinc content is 15-35wt%, and the iron content is 10-35%. [0003] In order to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B7/02C22B19/20C22B13/00C01G9/00C01G21/14

CPCC01G9/00C01G21/14C01P2006/80C22B7/007C22B7/02C22B13/045C22B19/22C22B19/26Y02P10/20

Inventor 栗克建尹在宏

Owner CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com