Mass pouring concrete temperature measuring and cooling method

A technology for pouring concrete and large volume is applied in the field of concrete pouring, which can solve the problems of inconvenience and difficulty in temperature measurement and cooling, difficult protection of temperature measurement components and temperature measurement wires, etc. Accurate and reliable data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The large-volume pouring concrete temperature measuring and cooling method of the present invention comprises the following steps:

[0036] a, prefabricated temperature measuring tube and cooling tube, including the following steps:

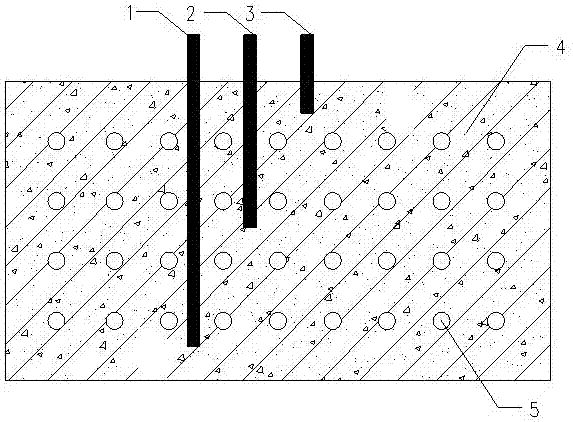

[0037] see now figure 1 , figure 1 It is a structural schematic diagram of pre-embedded temperature measuring tubes and cooling tubes in concrete according to an embodiment of the present invention.

[0038] (1) The temperature measuring tubes are made of DN20 steel pipes, and the bottom of the temperature measuring tubes is welded and sealed with steel plates; several thermometers are provided, and each temperature measuring tube is equipped with a thermometer, and the construction line passes through the round hole at the top of the thermometer and is free Lower it to suspend at a place 5cm from the bottom of the temperature measuring tube; the maximum range of the thermometer is 100°C.

[0039] (2) The cooling pipe 5 is made of DN50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com