One-room dual-temperature vacuum drying box and drying method

A technology of vacuum drying box and vacuum pump, which is applied in the direction of drying, drying machine, drying room/container, etc., which can solve the problems of product pollution and low efficiency, and achieve the effect of convenient operation, unique technology and high cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

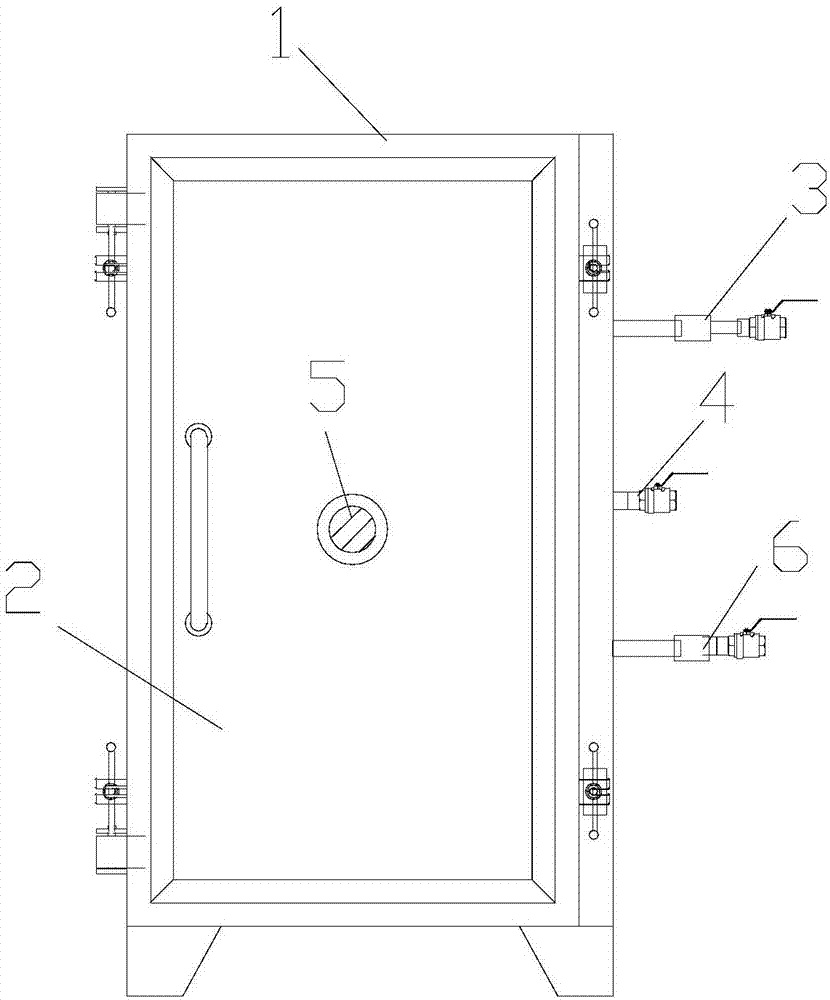

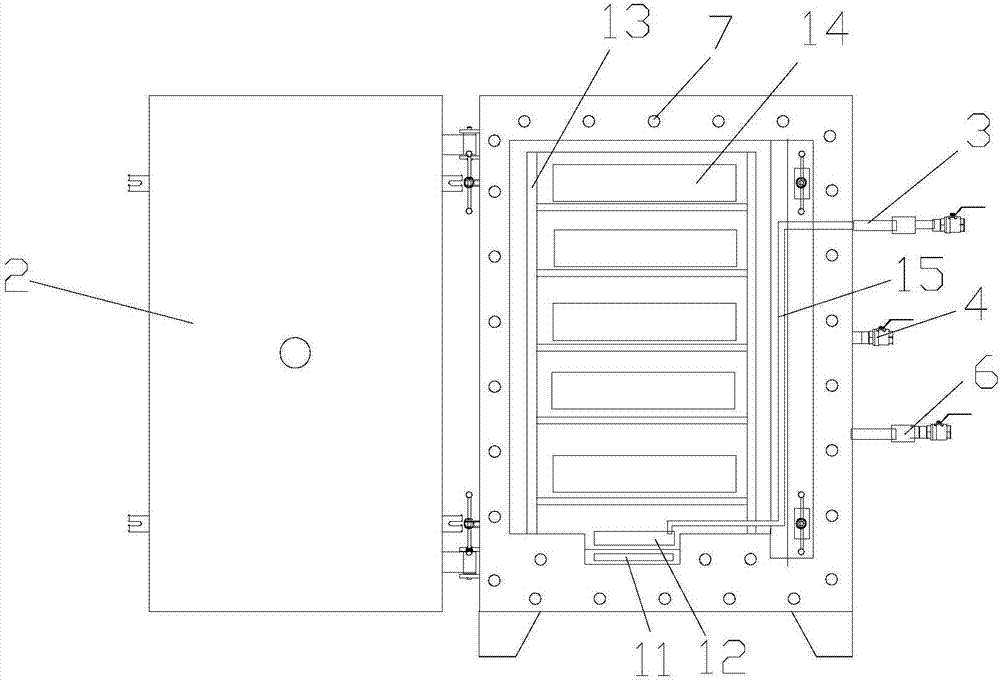

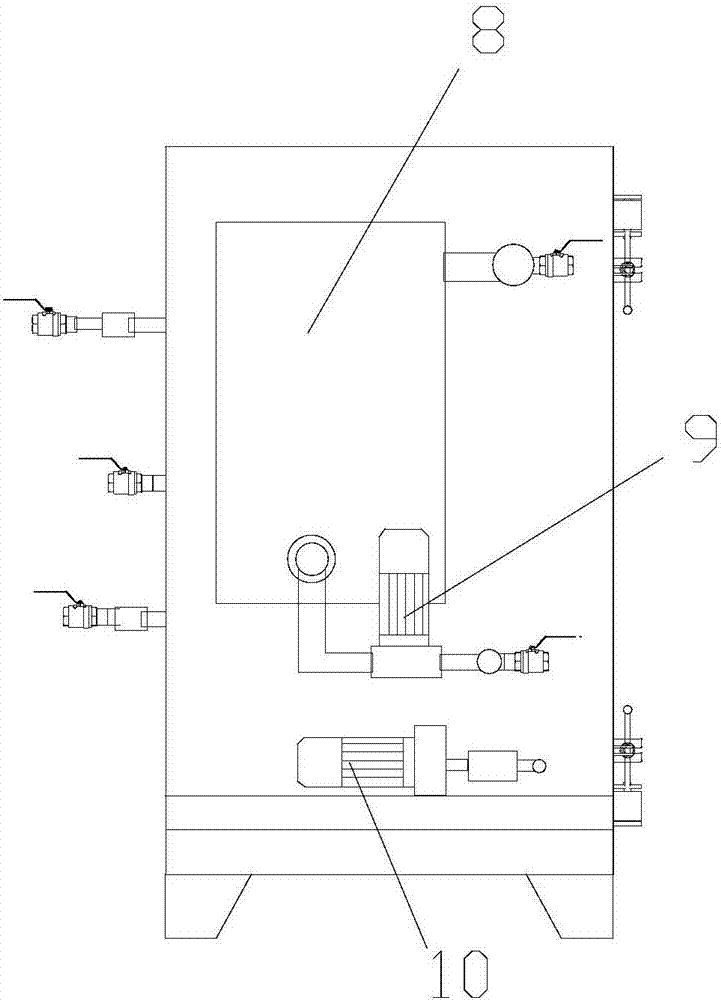

[0032] Such as Figure 1-3 As shown, a double-temperature vacuum drying oven with one chamber includes a furnace body 1 and a vacuum pump 10. The furnace body is provided with a vacuum interface, which communicates with the air inlet of the vacuum pump 10 through a pipeline, and the furnace body is provided with a first A heating device and a second heating device, the first heating device includes a heating water tank 8, a water pump 9 and a water pipe 7, wherein the water tank 8 and the water pump 9 are arranged outside the body of heater 1, and the water pipe 7 is arranged in the interlayer of the side wall of the body of furnace, The water inlet of the water pipe 7 communicates with the water outlet of the water pump 9, the water outlet of the water pipe 7 communicates with the water tank 8, and the water inlet of the water pump 9 communicates with the water tank 8 to form a hot water circulation loop. The water tank 8 is provided with an electric heating tube. The second ...

Embodiment 2

[0044] Utilize the method for drying in a double-temperature vacuum drying oven in one chamber, comprising the steps:

[0045] Step 1. Put the glass sheet into the baking tray, put the baking tray on the heat exchange support, close the furnace door, close the exhaust valve, and the furnace chamber is in a sealed state;

[0046] Step 2, start the second solenoid valve, start the vacuum pump, and evacuate the furnace chamber;

[0047] Step 3: Open the valve on the water pump, and the hot water circulates in the water pipe to heat the first chamber at a heating temperature of 70 degrees to dry the moisture on the surface of the glass sheet; at the same time, control the electric heating plate at the bottom of the second chamber to work , heating the second chamber, the heating temperature is 120 degrees;

[0048] Step 4. When the pressure in the chamber of the furnace body is -0.098MPa, the first electromagnetic valve is opened, and the liquid medicine is added to the material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com