Heating device for input smoke of SCR method denitration system

A heating device and denitrification technology, which is applied in lighting and heating equipment, waste heat treatment, gas emission reduction, etc., can solve problems such as difficulty in utilizing waste heat boilers, affecting denitrification reaction efficiency, flue gas temperature and heat not meeting requirements, etc. Achieve the effects of ingenious design, improved denitrification efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

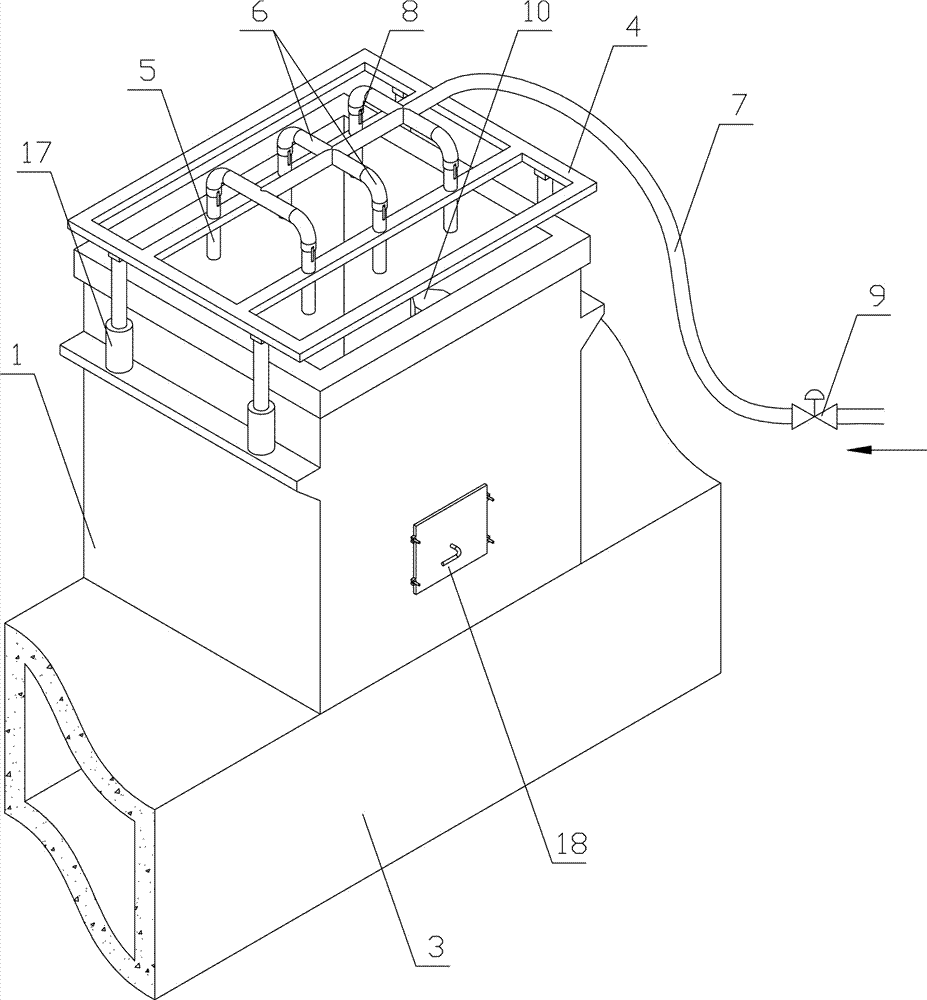

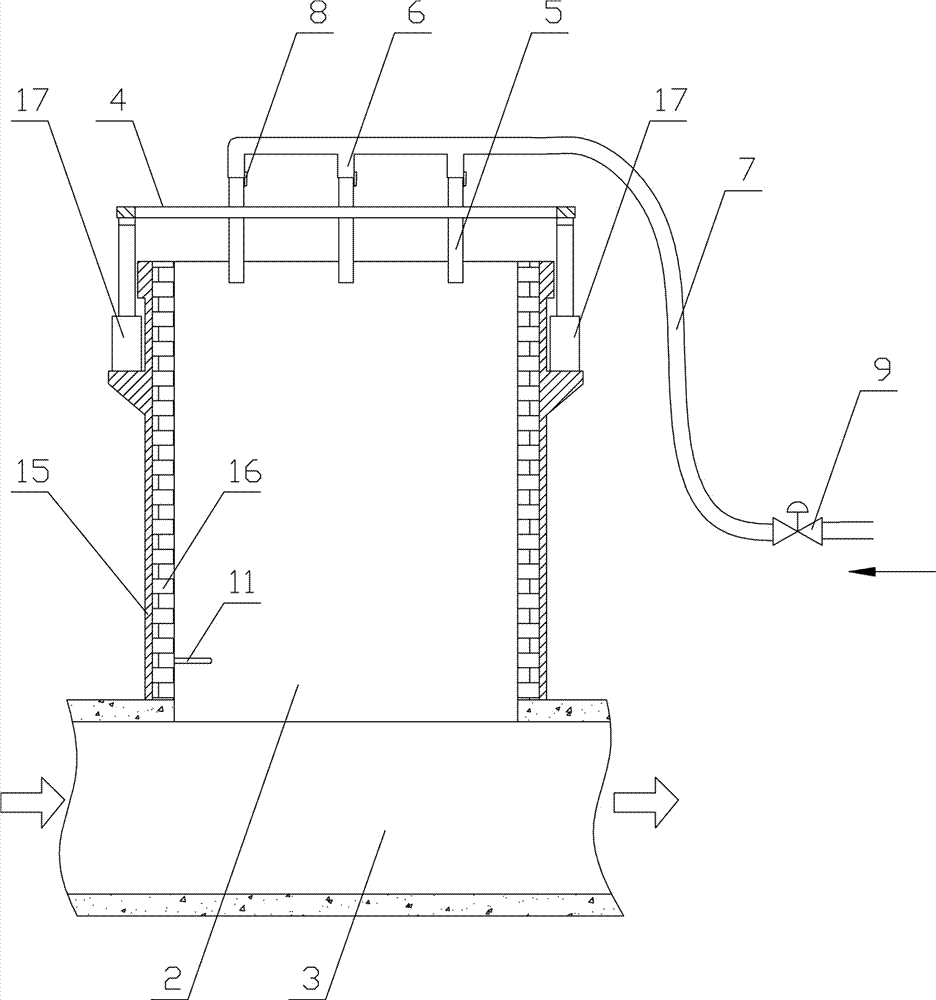

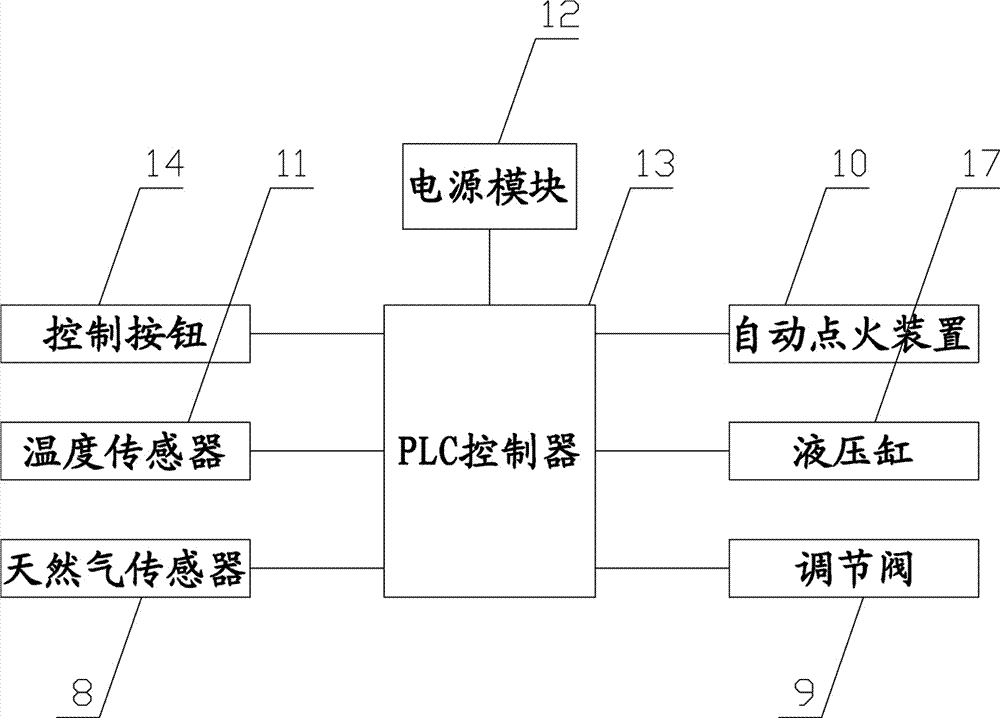

[0013] see Figure 1-3 , the present invention includes a regenerator 1 and its control system. The regenerator 1 has an inner cavity 2 for gas combustion and heat storage, and the upper end is open, and the lower end is connected to the flue gas channel 3 of the SCR denitrification system. 1 is provided with an elevating frame 4 on which several gas nozzles 5 are fixed, and each gas nozzle is connected to a gas delivery branch pipe 6, and all the gas delivery branch pipes 6 are connected with the gas delivery main pipe 7. A natural gas sensor 8 is provided at the joint between the gas nozzle 5 and the gas transmission branch pipe 6, and a regulating valve 9 is installed on the gas transmission main pipe 6, and the regulating valve 9 adopts a pneumatic regulating valve or an electric regulating valve; Automatic ignition device 10 is housed, and temperature sensor 11 is equipped with at the lower end; Described control system includes power module 12 and PLC controller 13 and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com